Glasses frame processing system and processing technology thereof

A processing system and processing technology technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of low manufacturing efficiency, low degree of automation, and poor quality of mirror frames, and achieve high work efficiency, high degree of automation, and cost savings Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The present invention will be further described below in conjunction with the accompanying drawings.

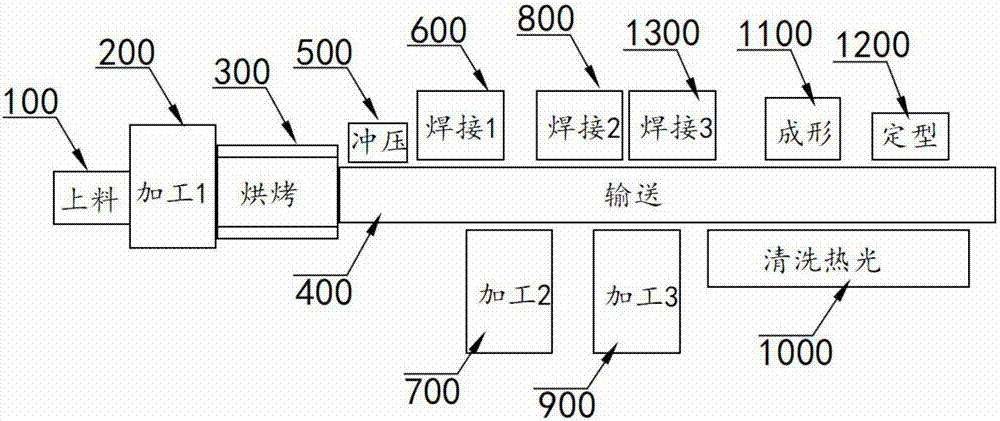

[0079] Such as figure 1 Shown is a schematic diagram of the present invention.

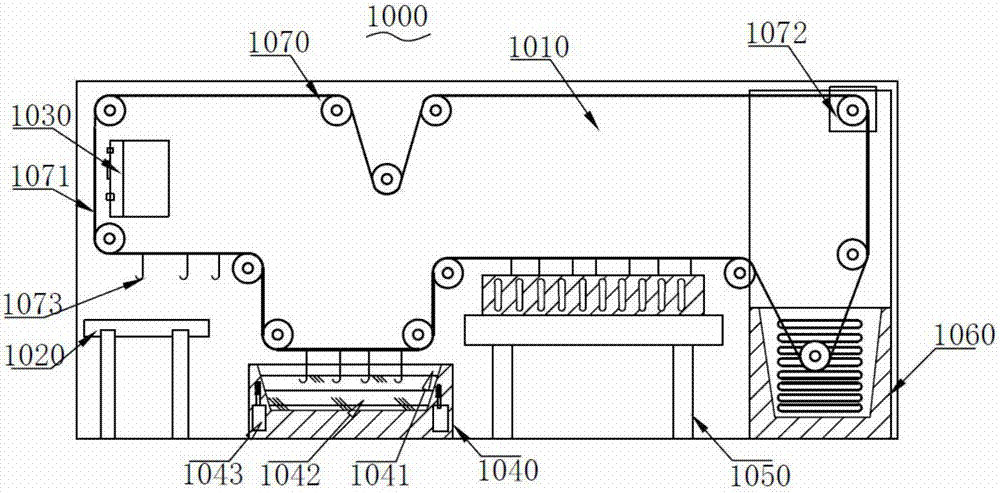

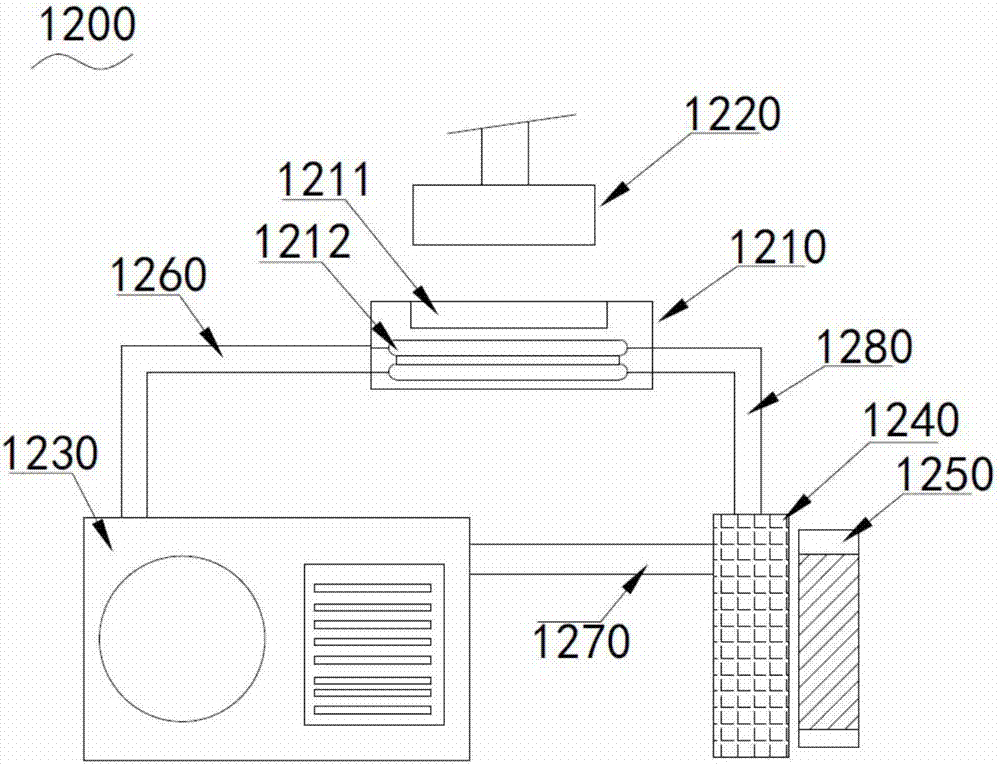

[0080] A spectacle frame processing system, comprising a feeding device 100, a first processing device 200, a baking device 300, a conveying device 400, a stamping device 500, a first welding device 600, a second processing device 700, a second welding device 800, The third processing device 900, the cleaning thermo-optic device 1000, the forming device 1100 and the setting device 1200; the conveying device 400 passes through the stamping device 500, the first welding device 600, the second processing device 700, the second welding device 800, the Three processing device 900, cleaning thermo-optical device 1000, forming device 1100 and sizing device 1200, one end of the baking device 300 is connected to the conveying device 400, and the other end is connected to the first processing devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com