Injection molding structure of a tee pipe fitting

A technology of three-way pipe fittings and injection molding, which is applied to tubular articles, household components, household appliances, etc., can solve the problems of weight change and production cost increase of three-way pipe fittings, and achieve the effect of improving hydraulic performance and avoiding welding marks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

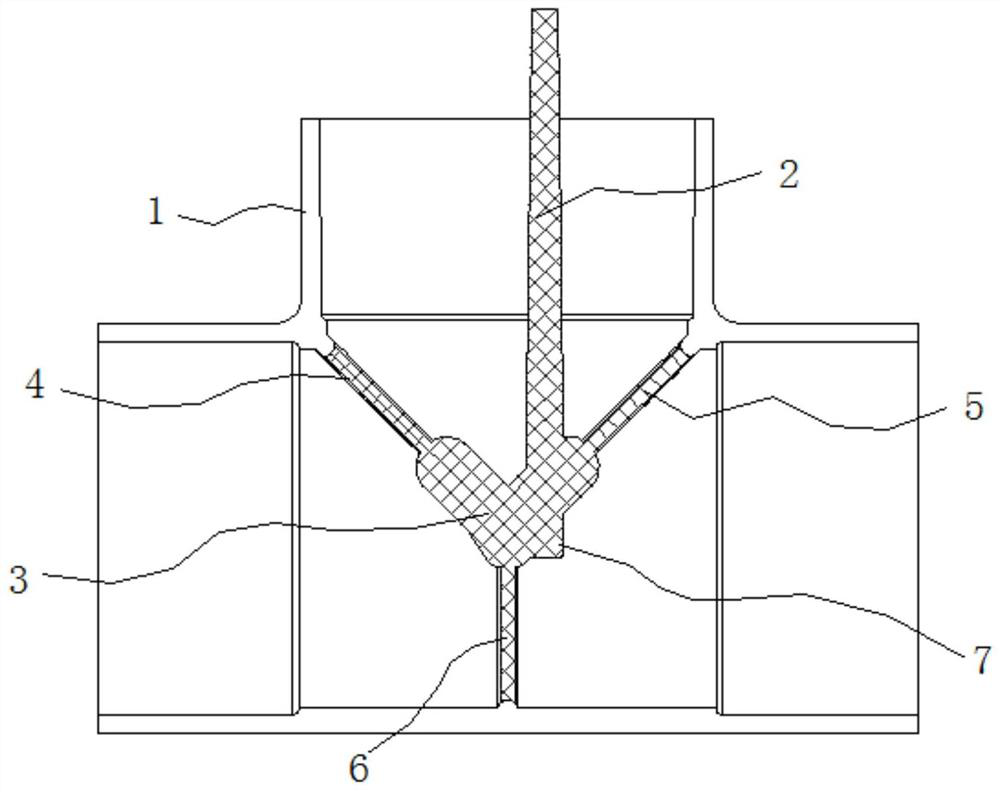

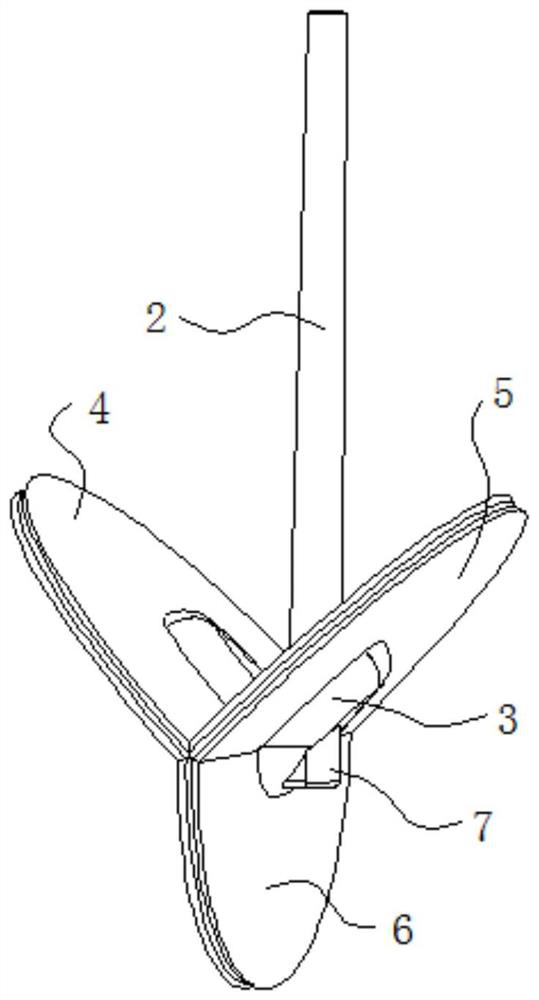

[0021] as Figure 1-2An embodiment of an injection molding structure shown as a three-way pipe fitting fixture, comprising a cavity 1 and a runner disposed in the cavity 1; the runner comprises a main gate 2, a storage portion 3 connecting the main gate 2 and a connected storage portion 3 and a distribution along the 3 circumferences of the storage portion 4, the second gate portion 5 and the third gate portion 6, the first gate portion 4, the second gate portion 5 and the third gate portion 6 are all connected to the cavity 1.

[0022] Among them, the first gate 4, the second gate 5 and the third gate 6 are Y-shaped. From the structure of the three-way pipe fittings, the connection of the tee pipe fittings is divided into three parts, namely the lower end part, the upper left part and the upper right part of the tee pipe fittings, through the Y-shaped distribution setting of the three gate parts, each gate part is injected into one of the parts, so that the melt flows in three dir...

Embodiment 2

[0029] Another embodiment of a fixture for the injection molding structure of a three-way pipe fitting, the difference with Example 1 is that the storage portion 3 is Y-type, the first gate portion 4, the second gate portion 5 and the third gate portion 6 are connected to the end angle of the storage portion 3, respectively, to ensure that the storage portion 3 is filled, the melt can be evenly dispersed to the three gates. There is a cold feed well 7 between the main gate 2 and the storage section 3. When the plastic melt passes through the main gate 2 runner, the front end of the cold material is stored in the cold material well 7 to avoid the cold material from affecting the effect of injection molding.

[0030] The remaining features and working principles of the present embodiment are consistent with Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com