Automatic cleaning system for nozzles of fully automatic intelligent spinning machines

A technology of automatic cleaning and automatic control system, applied in the direction of open-end spinning machine, spinning machine, continuous winding spinning machine, etc., can solve the problems of unstable air injection pressure, low air injection pressure, secondary pollution, etc. Achieve the effect of improving the qualified rate of spraying, simple control structure and high precision control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

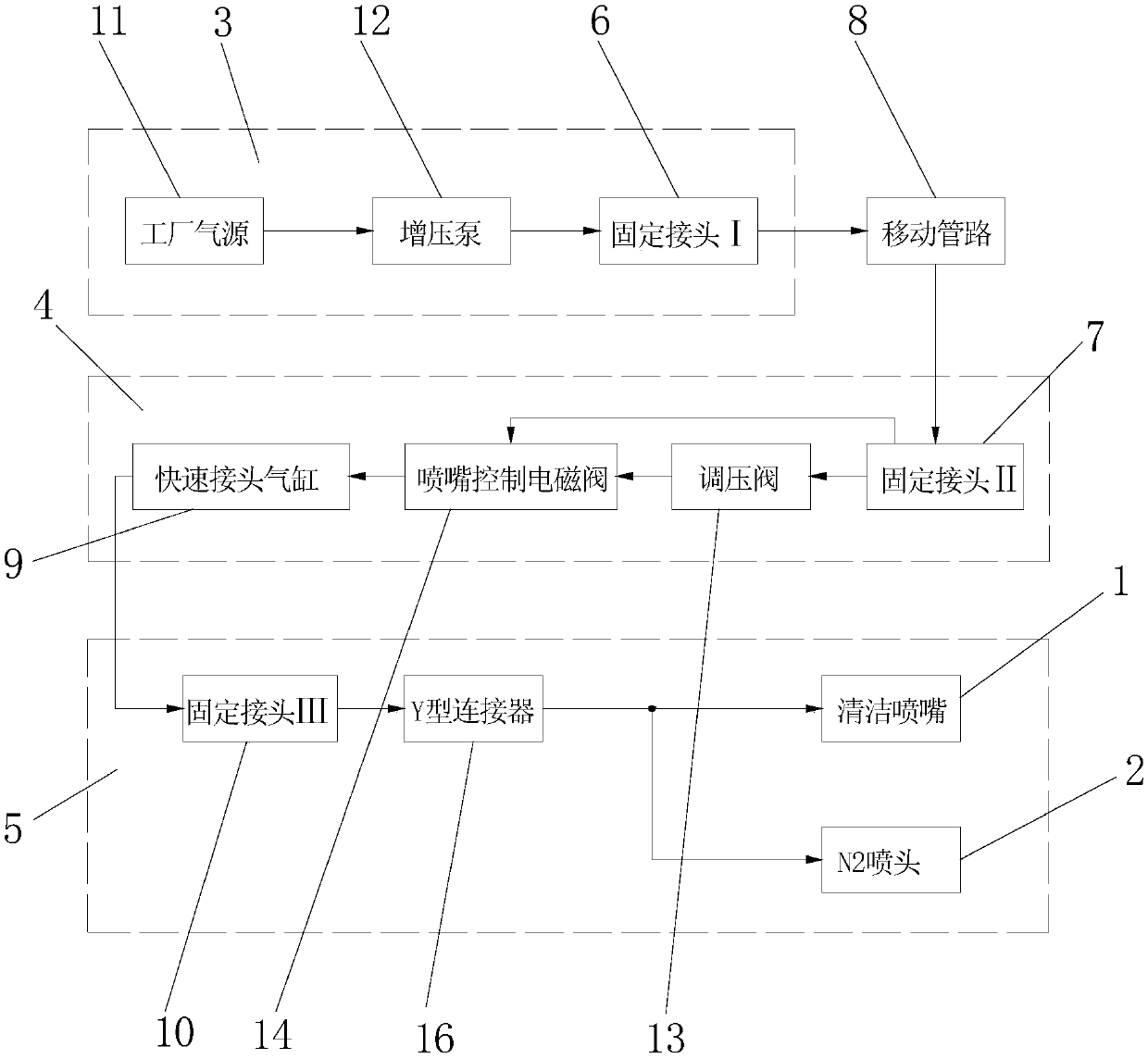

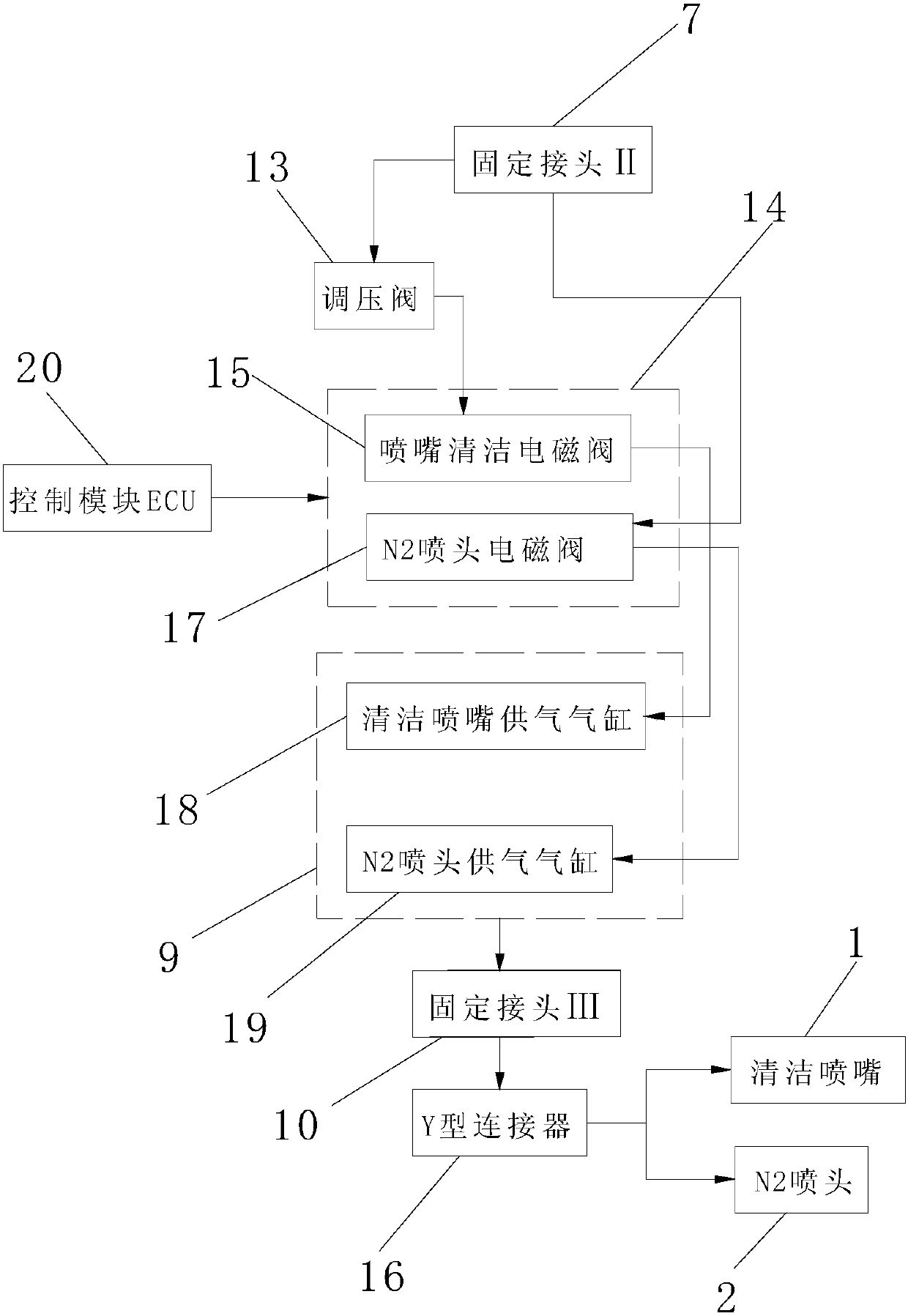

[0018] Attached below Figure 1-2 An embodiment of the present invention is described.

[0019] An automatic cleaning system for the nozzles of a fully automatic intelligent spinning machine, including an air supply system and an automatic control system, the automatic control system is connected to the air supply system and controls the air supply system to clean the nozzles in the air supply system according to the timing requirements 1 Complete the cleaning of the whole cleaning nozzle 1 and the pretwisting of the yarn by the whole N2 nozzle 2 after supplying air with the N2 nozzle 2; specifically, the air supply system includes a rear part 3, a plurality of mobile splicing cars 4 and several A spinning unit 5, the fixed joint I6 in the rear part 3 is connected to the fixed joint II7 in the mobile splicing car 4 through a moving pipeline 8, and then the air pressurized by the rear part 3 is transferred to the mobile splicer. On the connecting car 4, the quick joint cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com