Foot pad

A leather and pattern technology, applied in the field of foot pads, can solve the problems of non-waterproof, cumbersome process, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

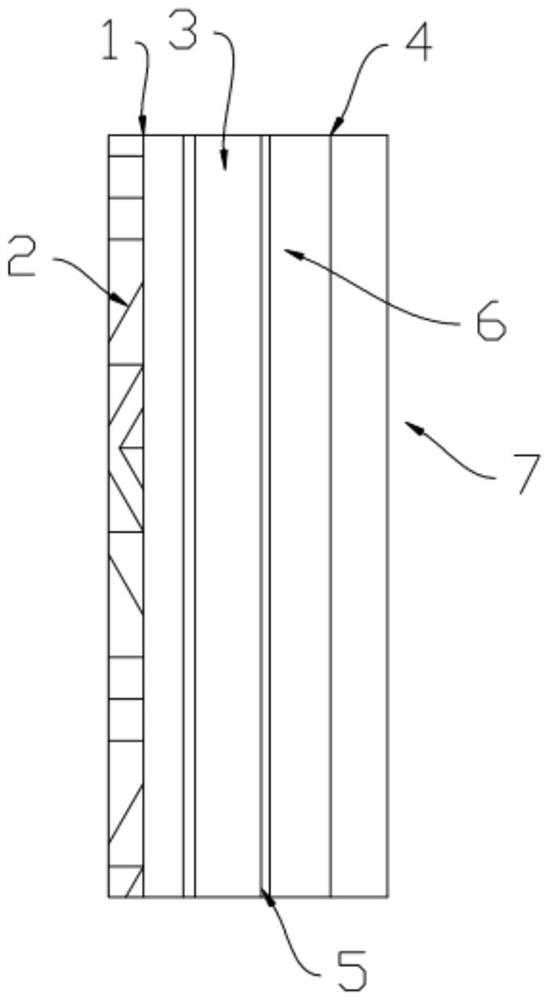

[0016] combined with figure 1 , a foot pad, which includes a leather 1, the outer surface of the leather 1 is provided with a pattern 2 produced by a letter-absorbing shaping process, and the inside of the leather 1 is provided with a high-density elastomer sponge 3, and the high-density The side of the elastic body sponge 3 away from the leather 1 is provided with a polyester hook cloth 4, and the adjacent sides of the leather 1, the high-density elastomer sponge 3, and the polyester hook cloth 4 are all bonded together by an environmentally friendly PUR hot-melt adhesive 5. connected.

[0017] Described absorbing letter shaping process he comprises the following steps:

[0018] S, put the leather 1 into the oven to heat, use the vacuum stick to set the pattern in advance, and then use the vacuum machine and the vacuum stick to shape the pattern on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com