Inclined sleeve assembling and positioning device and mounting method

A technology for assembling a positioning device and a positioning device, which is applied in the field of transformers, can solve problems such as damage to the casing, personal accident injuries of workers, and the casing is not fixed, and achieves the effects of ensuring safety, improving positioning effect, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

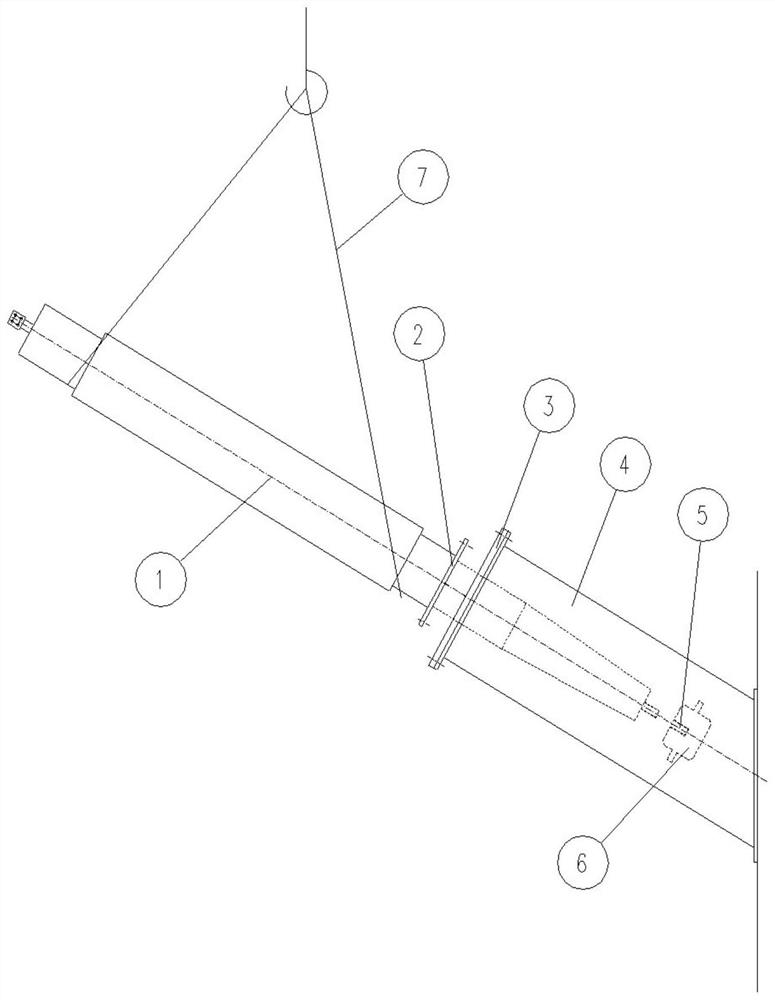

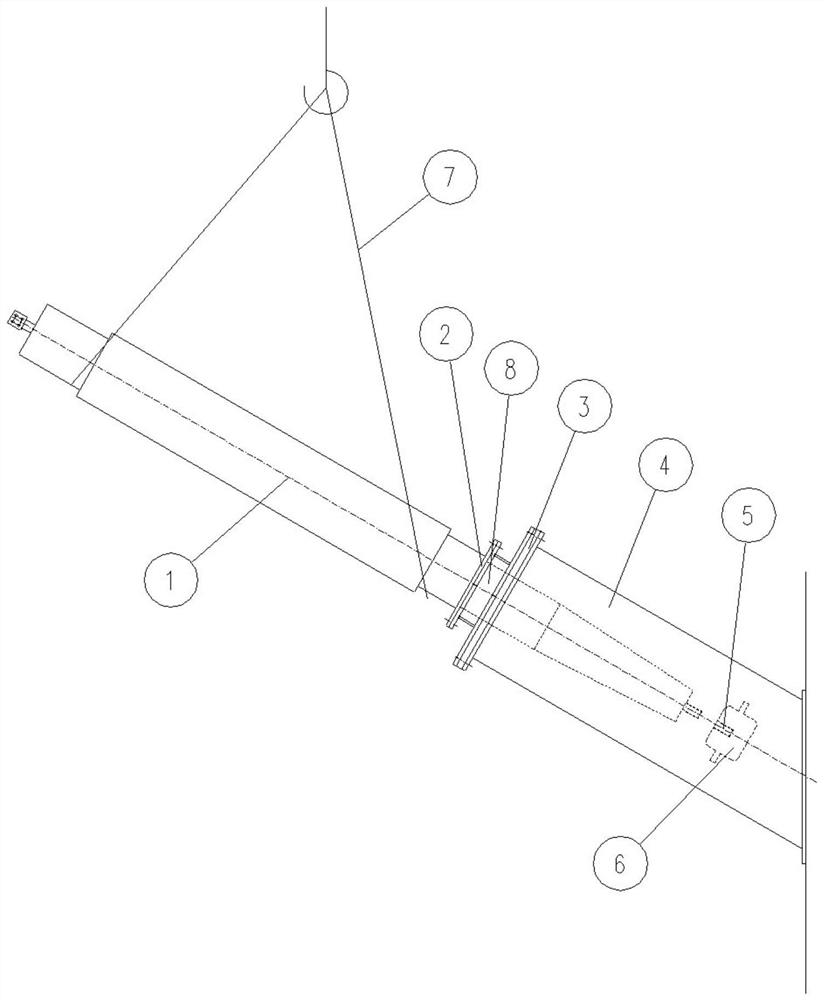

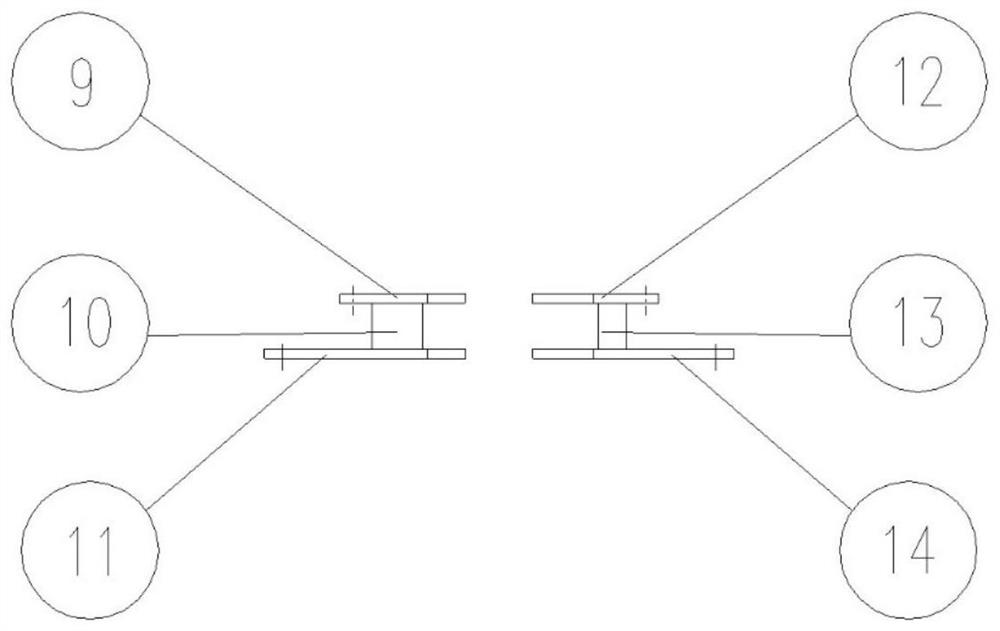

[0030] The invention discloses an installation method of an oblique-mounted casing assembly and positioning device. Before the casing 1 is hoisted and assembled, the connecting bolts between the casing installation flange 2 and the raised seat flange 3 are not installed, and the casing fixing bolts 5 and The casing fixing seat 6 is also loosened, and the casing lifting device 7 is used to raise the casing, and the casing 1 is inserted into the casing raising seat 4, and the inclined-mounted casing assembly positioning device 8 is inserted into the casing installation flange 2 and Between the flanges 3 of the raised seat, the upper flange 9 of the first positioning device is bolted and fixed to the casing mounting flange 2, the lower flange 11 of the first positioning device is connected and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com