Woven belt-shaped tassel weave and weaving method thereof

A tassel, ribbon-like technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of hook thread breaking, affecting the wearing effect, damage, etc., and achieve the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

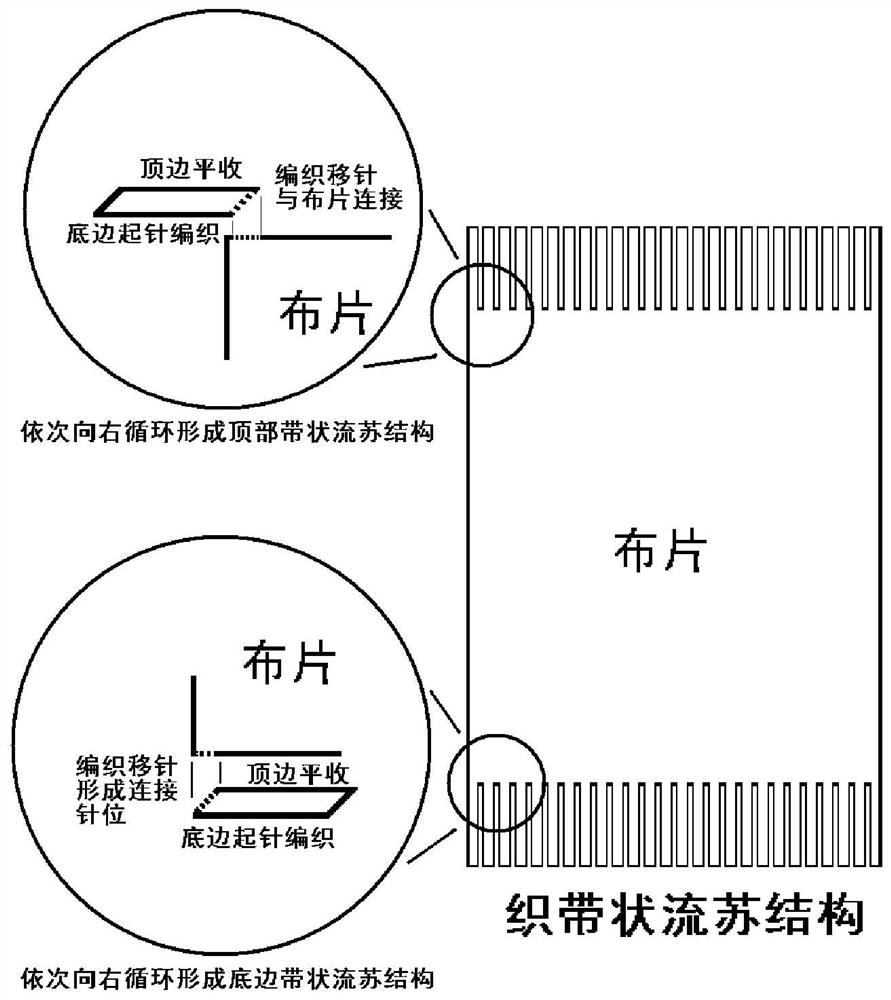

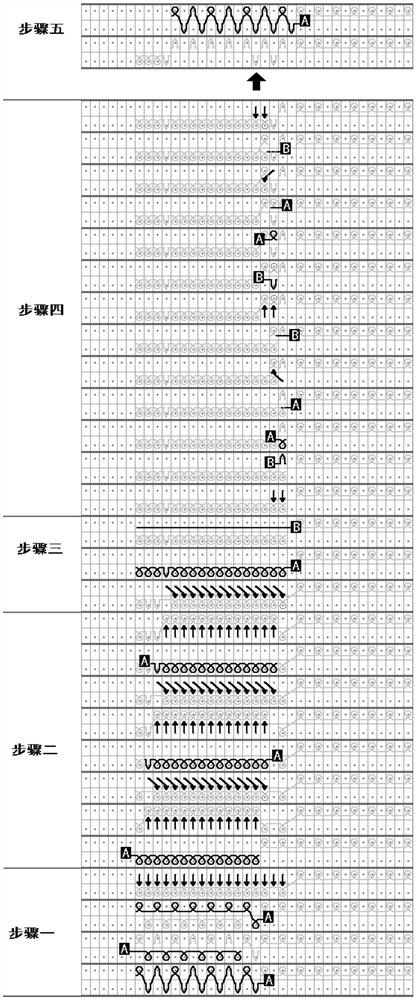

[0028]Such asfigure 1 As shown, a zipped taste structure includes a bottom web-shaped taste connected to the bottom of the fabric, and the bottom web strip-shaped runofa is composed of bottom web strip-shaped streams that are sequentially woven in the bottom of the fabric. The ribbon-shaped stream is subjected to the needle in the woven bottom of the woven, and the knitting of the edge coil is sequentially adjusted on the bottom of the fabric in the bottom of the fabric, and the width of the web is required to weave a certain number of lines according to the width of the web. It is formed to be formed. Further, it is also possible to include a top web-shaped taste connected to the top of the fabric, and the top web-shaped taste is composed of top web strip-shaped streams that are sequentially woven on the top of the fabric, and the top web strip is passed in the fabric. The null needle position is knitted, and the knitting of the knitting is complicated with the thickness of the edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com