A prefabricated staircase and its installation process

A technology for stairs and installation platforms, which is applied in the direction of stairs, ladder-like structures, pedals and riser units, etc. It can solve the problems of easy collision with foreign objects, pressure from foreign objects, and small thickness of joints, so as to facilitate classification and transportation , reduce the probability of collision, improve the effect of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

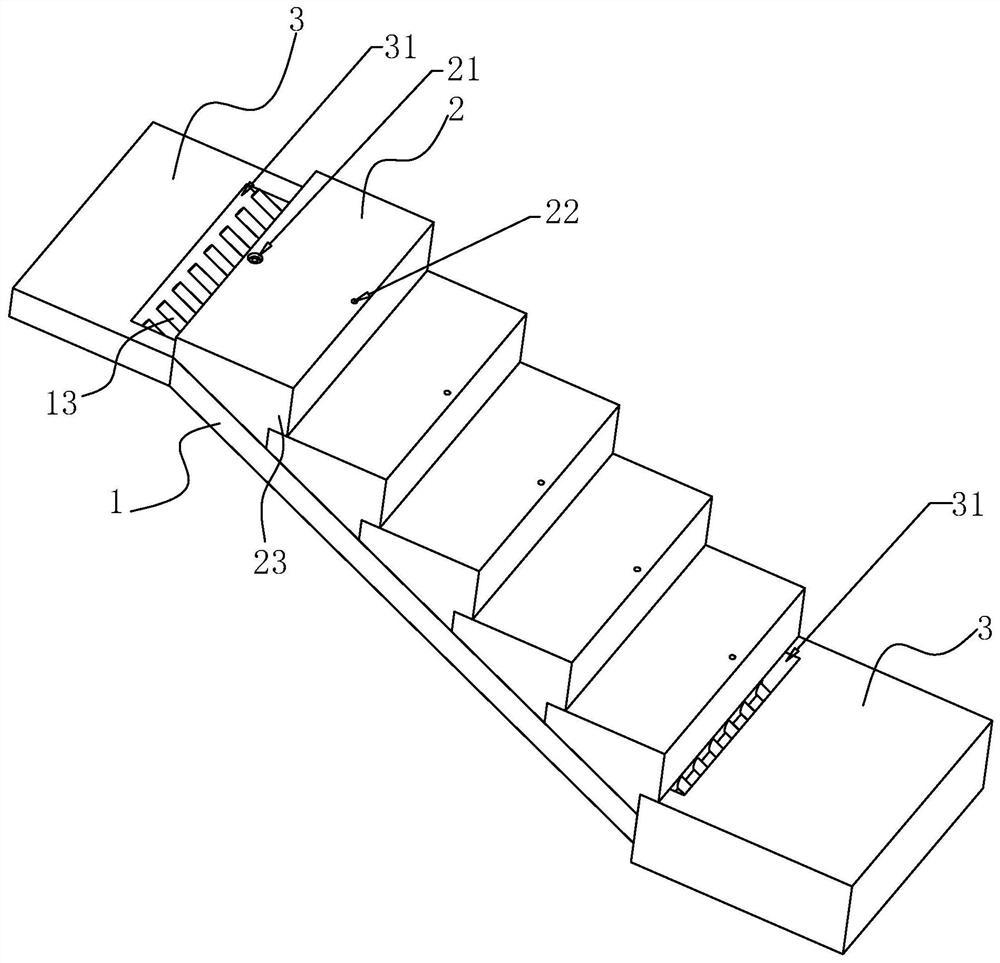

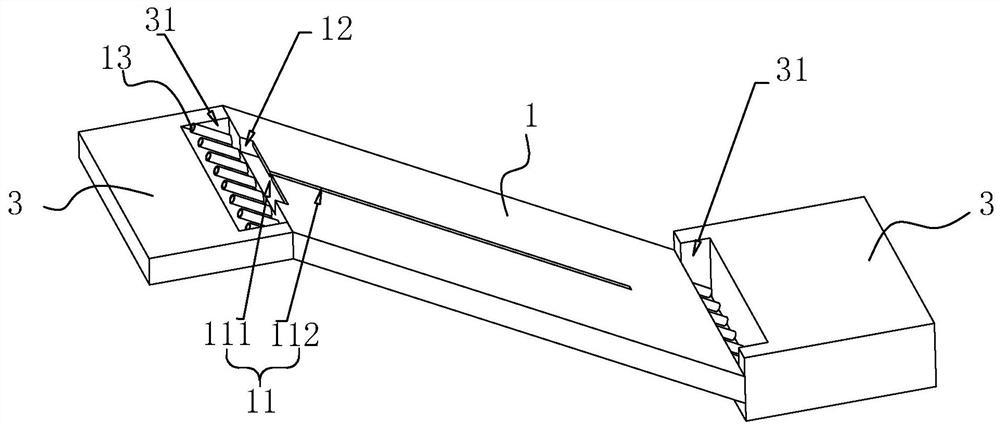

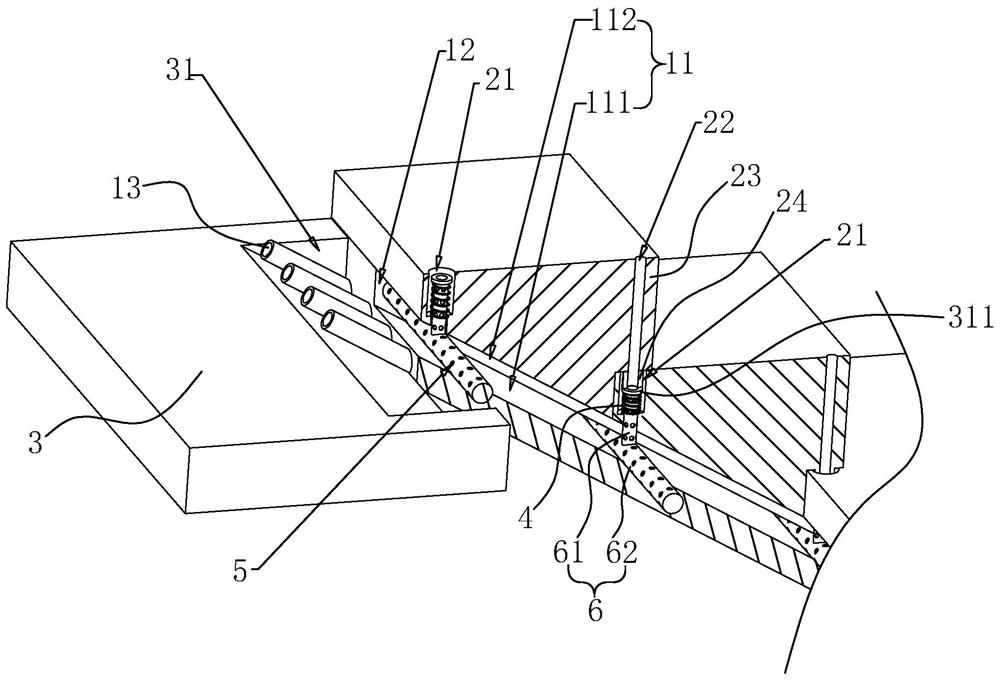

[0036] Contraction below Figure 1-3 Further detailed description of the present application.

[0037] The present application discloses a prefabricated staircase and its installation process. Refer figure 1One prefabricated staircase includes a substrate 1 that is inclined, two mounting tables 3 that are fixed at the upper beam and the lower beam, respectively, and several block step units 2, respectively. The two-piece mounting table 3 is connected to the side of the bottom plate 1, and the connecting groove 31 communicates with the upper end surface of the mounting table 3, and the bottom plate 1 is embedded with several root connecting tubes 13, and several connect tubes 13 all along the bottom plate 1 length. The direction extends and the connecting tube 13 projects both ends of the bottom plate 1, and the plurality of connect pipes 13 are distributed in the width direction of the bottom plate 1. The two ends of the connecting tube 13 are respectively engaged in the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com