Intelligent spring support system with load convenient to debug

A spring bracket and intelligent technology, applied in the field of spring brackets, can solve the problems that the measurement accuracy is greatly affected by temperature, humidity and patch quality, the debugging is difficult, and the efficiency is low, so as to achieve real-time accurate monitoring of load and displacement, and overcome the load. The effect of the column being easily skewed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

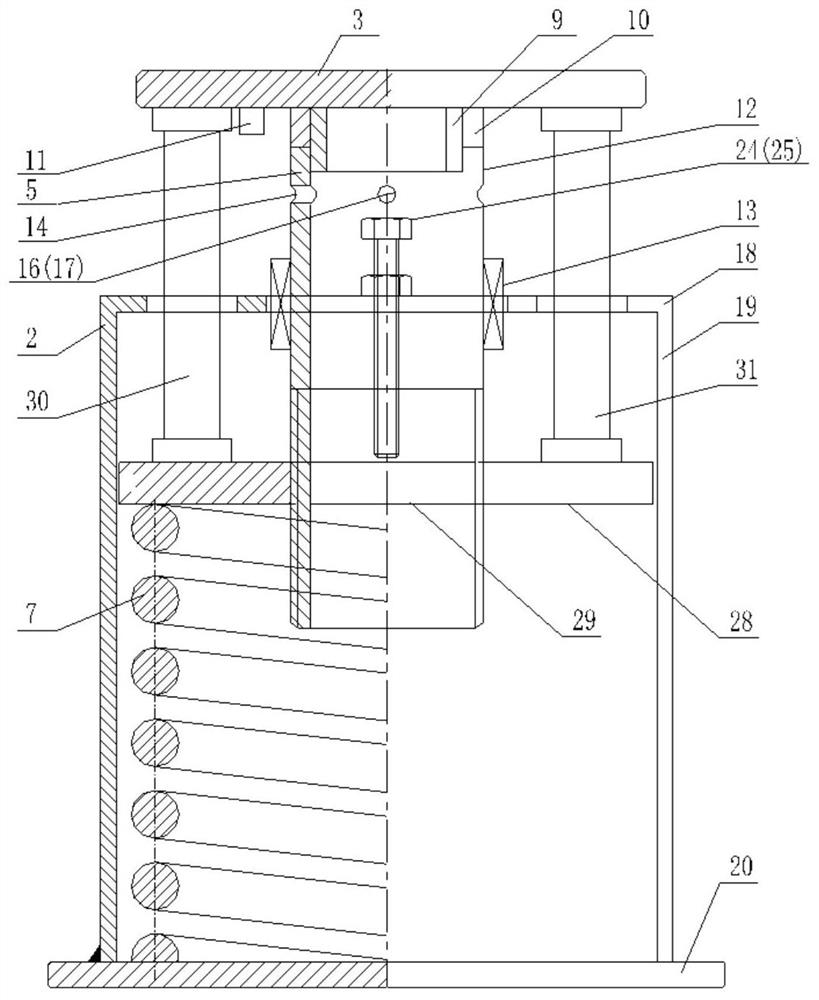

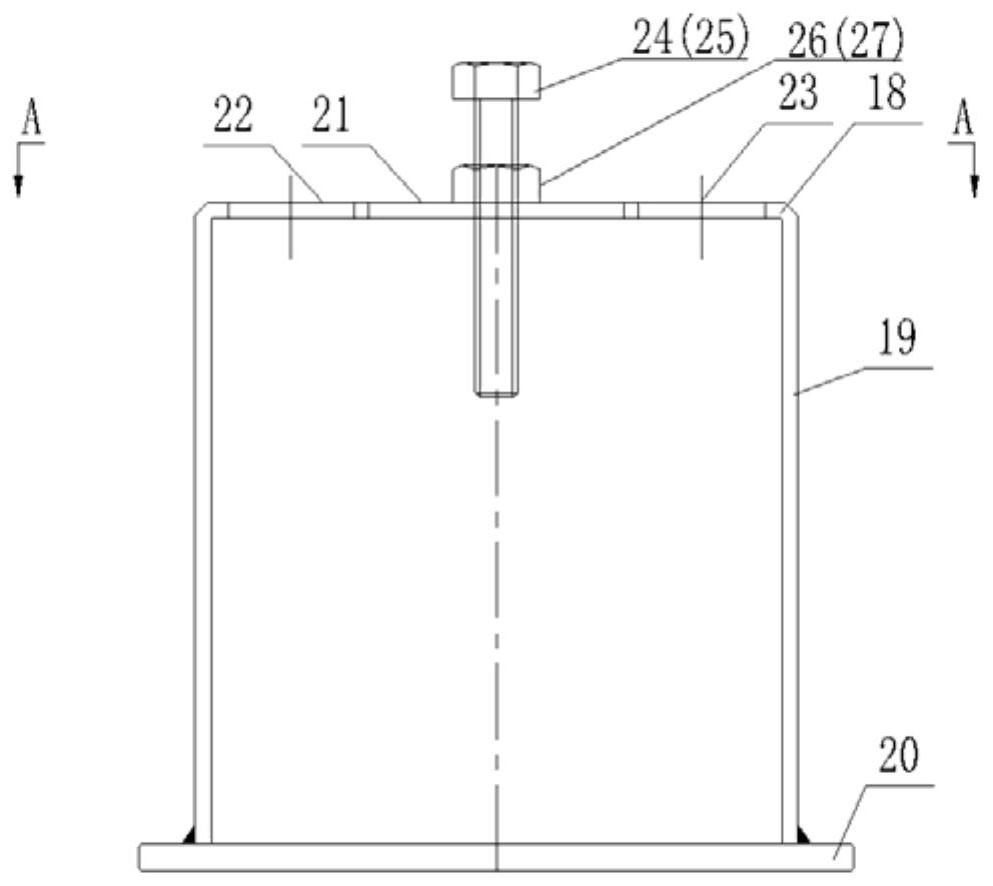

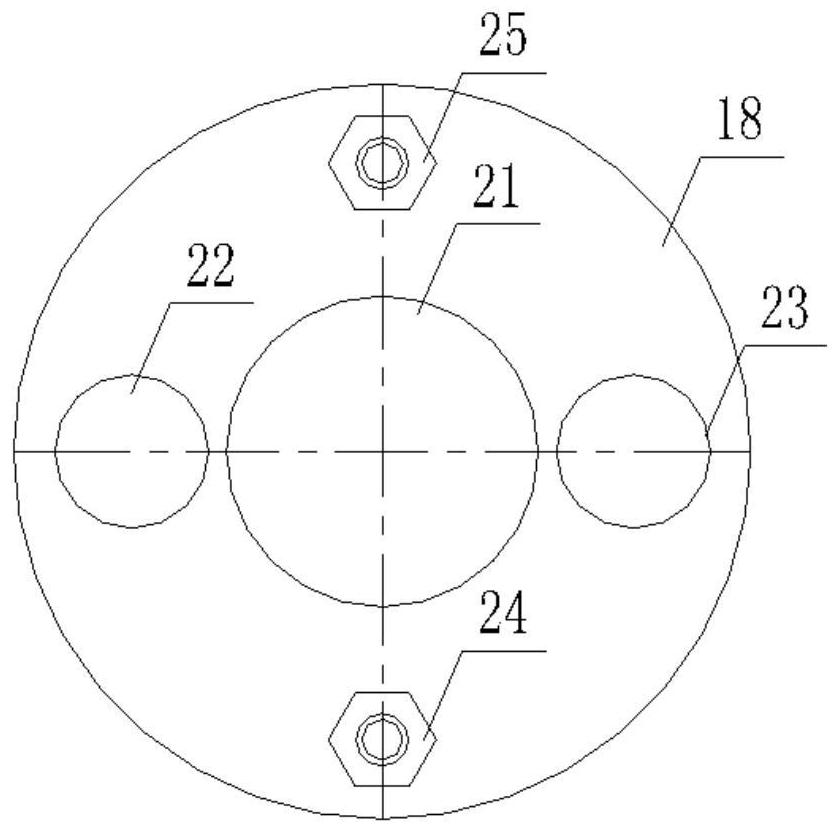

[0031] The present invention is described in further detail below in conjunction with accompanying drawing:

[0032] refer to Figure 1 to Figure 8 , the intelligent spring support system for easy debugging of the load according to the present invention includes a cover tube assembly 2, a cover plate assembly 3, a pillar 4, a data collection module 5, a first locking bolt 24, a second locking bolt 25 and an intelligent management Module 6; the cover tube assembly 2 includes a first cylinder 19, a top plate 18 fixed at the top opening of the first cylinder 19, and a bottom plate 20 fixed at the bottom opening of the first cylinder 19; the circular top plate 18 is provided with a second A round hole 21, a second round hole 22 and a third round hole 23, wherein the second round hole 22 and the third round hole 23 are respectively located on both sides of the first round hole 21, and the lower end surface of the spring 7 is fixed on the base plate 20 Above, the upper end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com