Bucket elevator measuring and calculating device

A technology of bucket elevator and bucket elevator, which is applied in the direction of conveyor control device, transportation and packaging, combustion method, etc. It can solve the problems of affecting production heating, personnel cannot observe in fully sealed state, missing detection and slipping device, etc., and achieves guarantee The effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The following are specific examples of the present invention, further describing the technical solutions of the present invention, but the protection scope of the present invention is not limited to these examples. All changes or equivalent substitutions that do not depart from the concept of the present invention are included in the protection scope of the present invention.

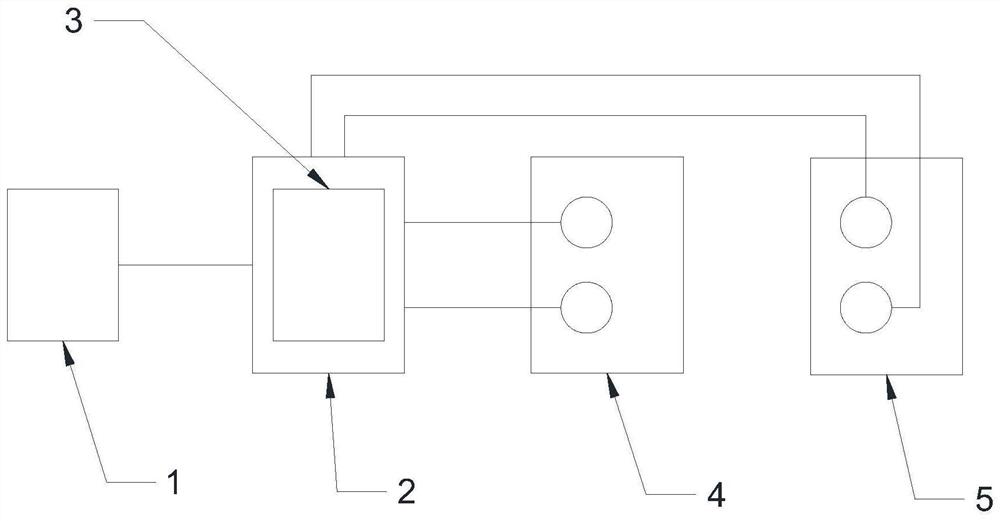

[0012] Such as figure 1 As shown, a bucket elevator measuring and calculating device includes a touch display screen 1, PLC2, a speed measuring switch and a pulverized coal bucket elevator. 5 are respectively set on the left and right sides of the pulverized coal bucket elevator, the speed measuring switch 1 4 and the speed measuring switch 2 5 are connected to PLC2, PLC2 is connected to the touch screen through the signal line, and the touch screen 1 is set in the hot blast stove duty room, touch The display screen 1 is provided with an audible and visual alarm.

[0013] Further, the PLC2 incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com