Molded case circuit breaker

A technology of molded case circuit breaker and casing, which is applied to circuits, parts of protection switches, electrical components, etc., can solve the problems of inconvenient disassembly and assembly of plastic casings, poor heat dissipation effect, etc., so as to improve the protection effect, improve the heat dissipation effect, Effect of stable temperature environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

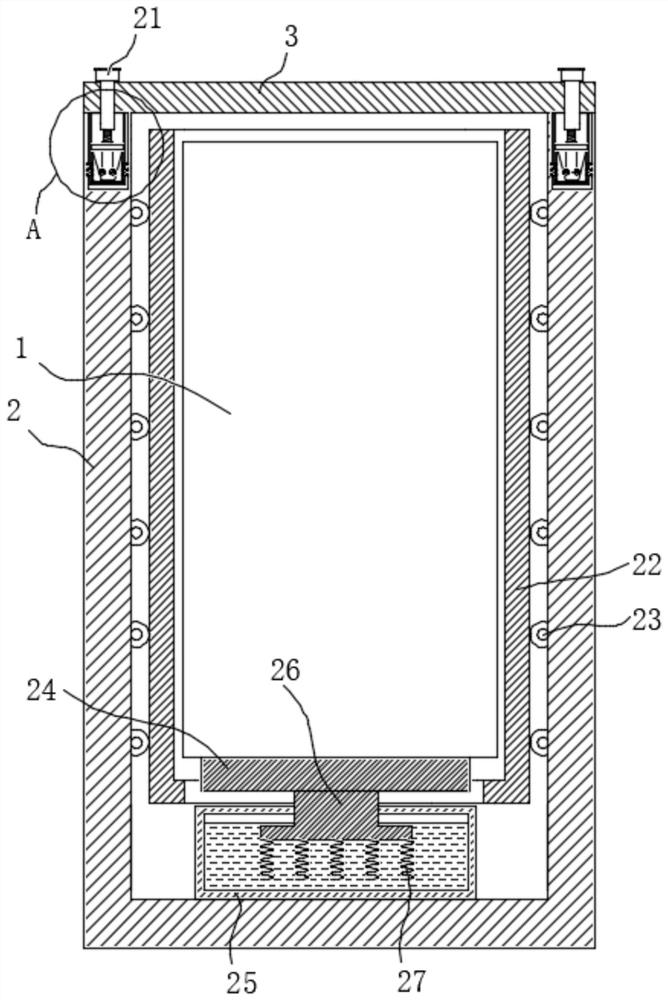

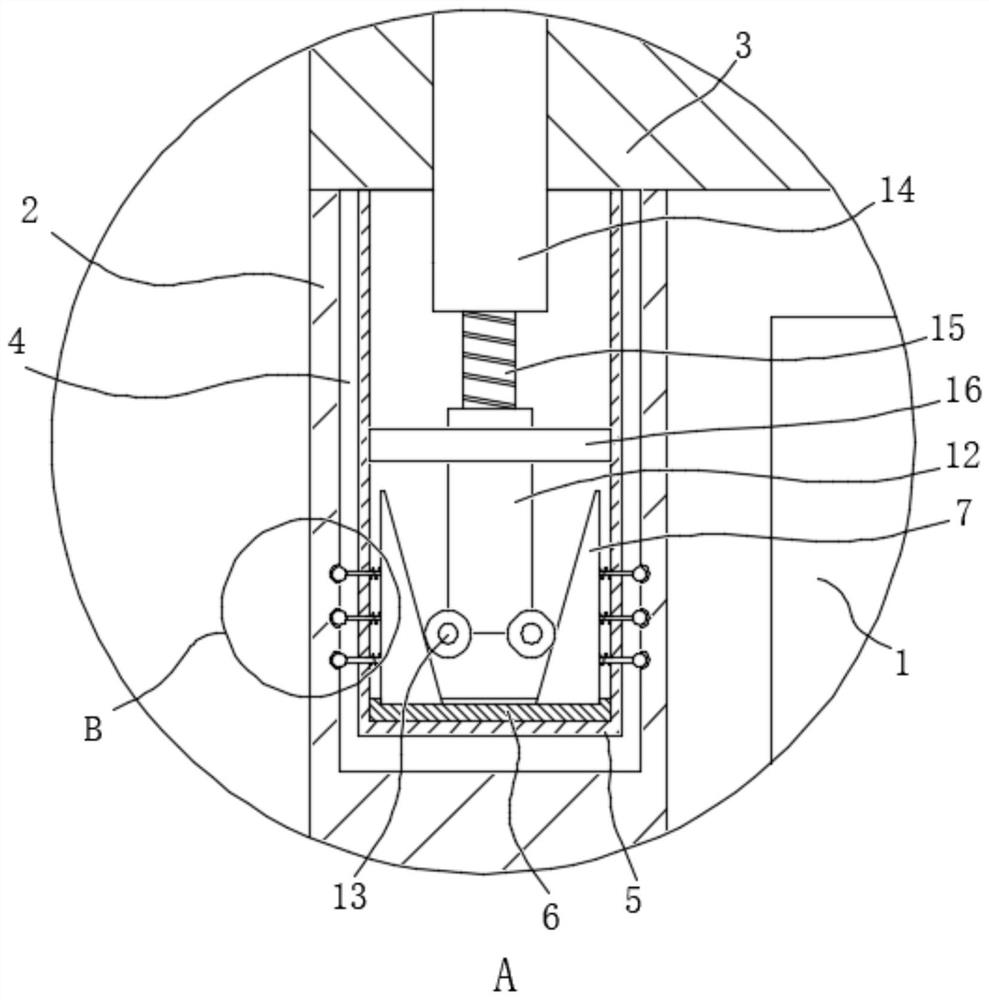

[0035] Please combine Figure 1 to 3 The molding case circuit breaker includes a plastic case circuit breaker body 1, and the outer cover of the plastic case circuit breaker main body 1 is provided with a housing 2, and the outer cover of the molding case circuit breaker main body 1 is provided with a housing 2, and the housing 2 is reserved. The beam line passing through the harness of the shell circuit breaker main body 1 (not shown). One end of the housing 2 has an insertion port (not indicated) inserted from the plastic shell circuit breaker main body 1, and the housing 2 is provided with a housing cover 3 for closing the insertion. Through the housing 2 and the shell cover 3, the plastic case circuit breaker main body 1 can be improved to avoid the operation of the external environment affects the molding circuit breaker.

[0036] The housing cover 3 is disposed on one side of the housing 2 with an interior hollow adapter block 5, and the housing 2 is opened, and the adapter ...

Embodiment 2

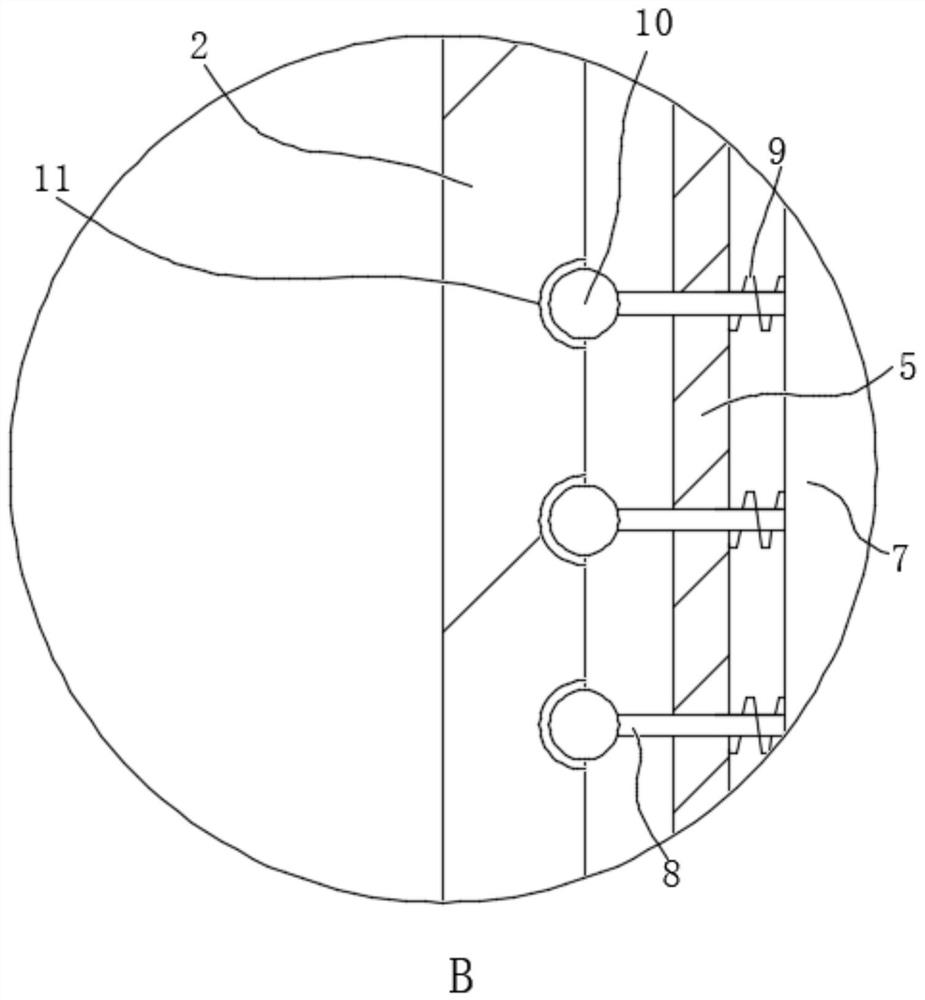

[0052] Please combine Figure 4 to 6 The present embodiment is an improvement scheme of Example 1. Specifically, both sides of the casing 25 are provided with a pair of linked seats, and each of the pair of receiving grooves 30, the carrier cartridge 22 facing the box 25 One side is provided with a pairing block 28 that cooperates with the tang 30, and between the pair of pieces 28 and the pairing groove 30 are engaged. The carrier cartridge 22 can be more smooth and reliable by the engaging of the pair of ligated grooves 28 and the pair of ligated blocks 28, and the launch of the carrier 22 can be more smooth and reliable.

[0053] A bead groove 28 is opened on the block 28, and the top beads 33 are connected by the spring die 33 in the bead tank 34, and the top groove 2 31 that cooperates with the top beads 2 32 is opened. Among them, when the spring 23 does not have a deformation, the pending 32 of the pending die 32 is flat to the slots of the bead groove one 34.

[0054] When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com