Small joint suture threader

A threader and joint technology, which is applied in the field of small joint suture threader, can solve the problems such as difficulty in successfully completing the threading process of suture needles, low efficiency of manual threading, and increased difficulty in operation, so as to achieve a delicate and smooth overall structure and avoid stabbing human tissues , the effect of reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

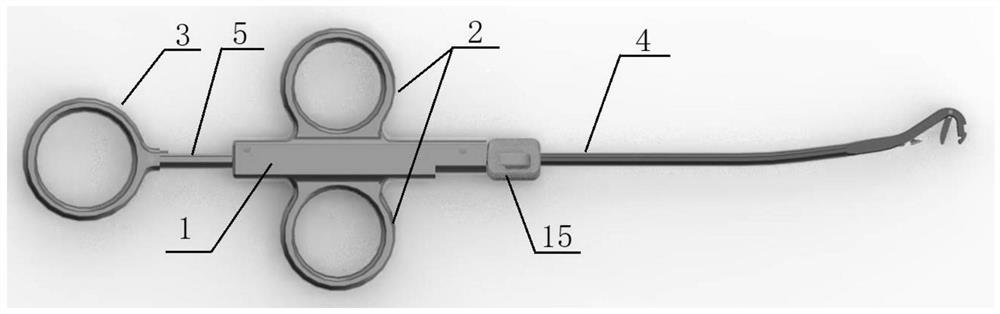

[0028] Such as figure 1 Shown is a preferred embodiment of a facet joint suture threader of the present invention, which mainly includes a handle part, an extension part 4 and a clamping part connected in sequence. The handle part includes the shell 1 and the bionic ring 2 on the shell 1. The smooth design and layout of the ring conform to the bionic structure, and the grip is more comfortable, enabling long-term operation without fatigue.

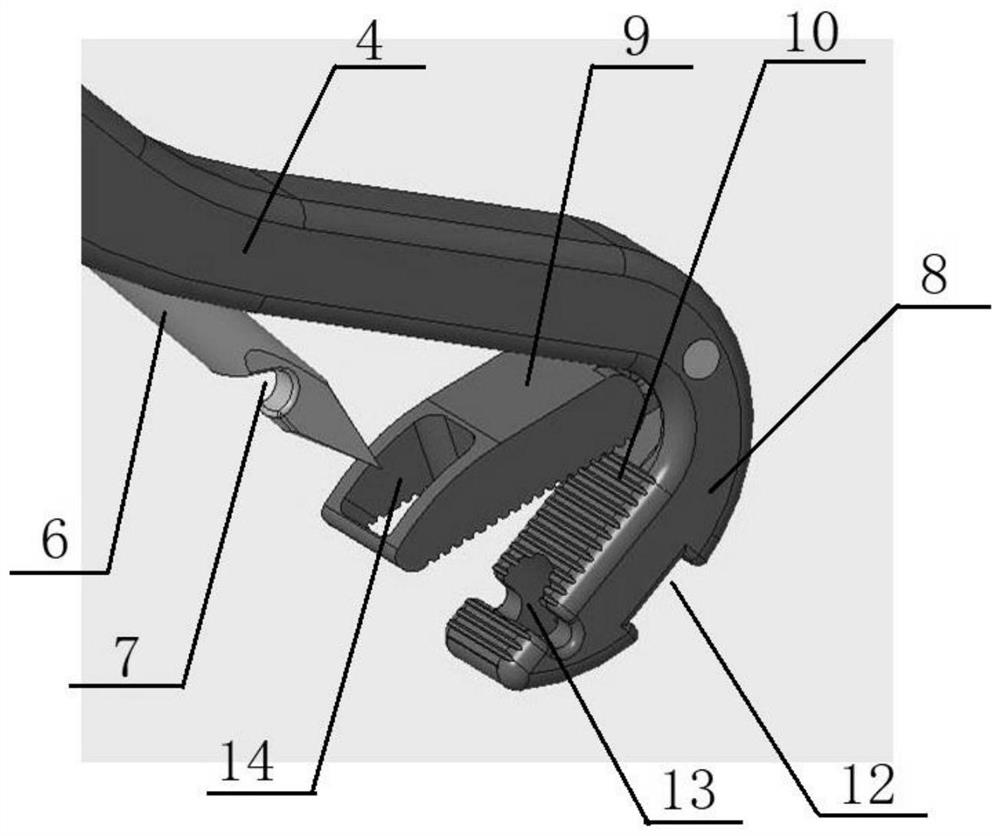

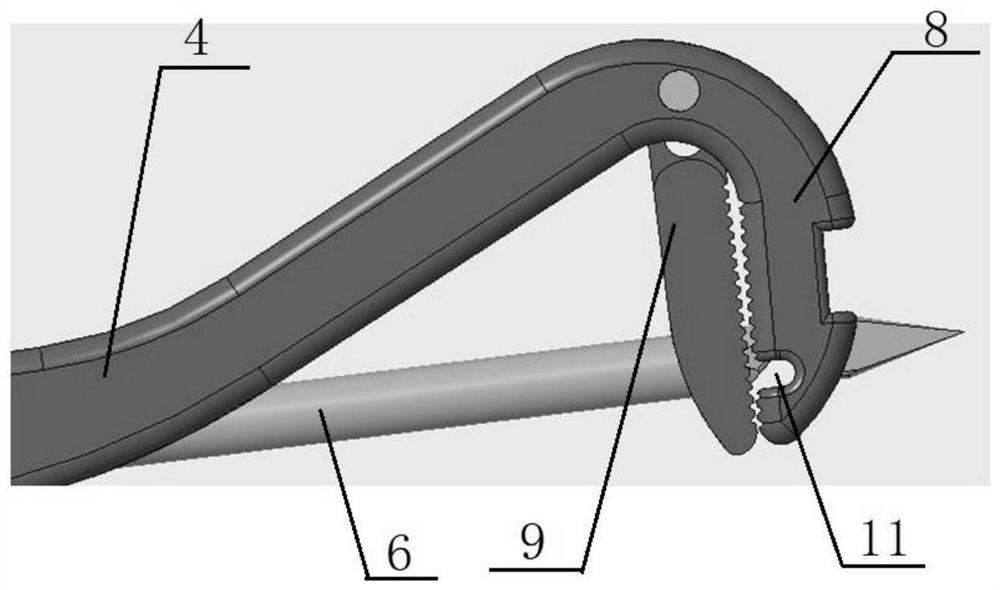

[0029] The front end of the extension part 4 is provided with a clamping part for clamping soft tissue, and a threading needle 6 is pierced in the extension part 4, and a thread hook groove 7 is provided on the threading needle 6. There is a push needle mechanism for pushing out and pulling back the threading needle. When pushing out, the threading needle penetrates the soft tissue and hooks the suture into the hooking groove, and then hooks the suture back when pulling back.

[0030] Further, the handle part is provided with a clamping m...

specific Embodiment approach

[0050] When threading, first wrap the suture thread in the U-shaped harness groove 11 of the outer jaw 8, then hook the outer jaw 8 on the inside of the soft tissue (such as tendon, ligament) to be sutured, and place the inner jaw 9 on the outside of the soft tissue , and then press down on the near-end finger ring 3 to drive the inner jaw 9 to close to clamp the soft tissue, and at the same time drive the threading needle 6 to push out, pass through the waist hole 14 on the inner jaw 9 and the soft tissue into the U-shaped wire harness groove 11 for threading the needle into the hole 13, hook the suture in the U-shaped wire harness groove 11 into the thread hook groove 7, and finally loosen the proximal finger ring 3 (or actively pull it back), drive the threading needle 6 to retreat, and pull the suture thread from the soft tissue to the The side is pulled over (the belt thread passes through the soft tissue), and the inner jaw 9 is opened (relaxing the clamping) simultaneous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com