Kitchen garbage disposer

A kitchen waste and processing machine technology is applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., which can solve the problems of costing a lot of electricity, kitchen waste is easy to stink, etc., and shorten the drying time. , The effect of uniform distribution and few parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

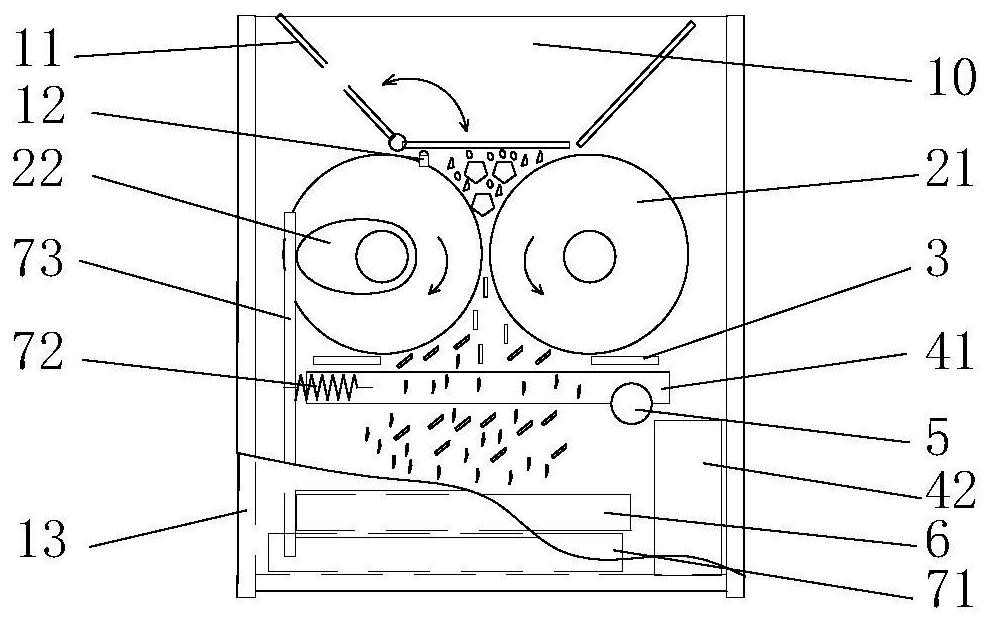

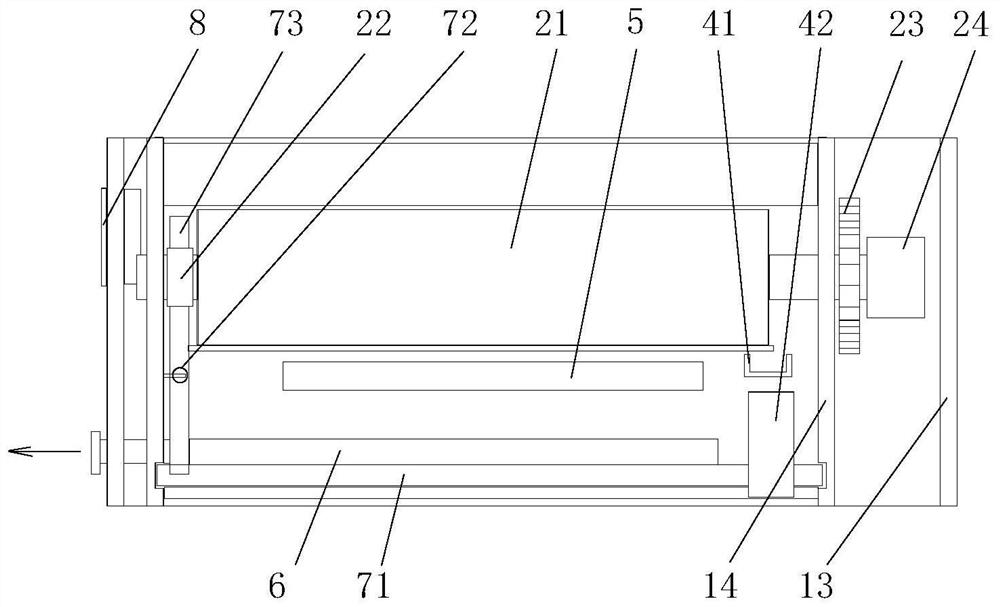

[0030] Now in conjunction with accompanying drawing, the present invention will be further described:

[0031] As shown in the figure, a kitchen waste disposer includes:

[0032] Housing 13, the top of which is provided with kitchen waste inlet 10;

[0033] frame 14, which is fixed in the housing 13;

[0034] Squeeze roll 21, be provided with a pair of and the end face of squeeze roll 21 is high at one end and low at one end, from figure 2 Seen from above, the left end is high and the right end is low, and its two ends are rotatably fixed to the frame 14 respectively, and the kitchen waste in the kitchen waste inlet 10 can be squeezed dry after being passed between a pair of squeeze rollers 21; It can flow from the high end to the low end along the press roll 21;

[0035] A pair of gears 23 are provided, which are respectively fixed to the rotating shafts of a pair of press rolls 21, and the pair of gears 23 mesh with each other;

[0036] The motor 24 is usually a deceler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com