High-precision press fitting tool for camshaft timing gear and signal panel

A timing gear and press-fitting tooling technology, which is applied in manufacturing tools, workpiece clamping devices, hand-held tools, etc. Easy to install, reduce the possibility of press-fitting failure, and improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

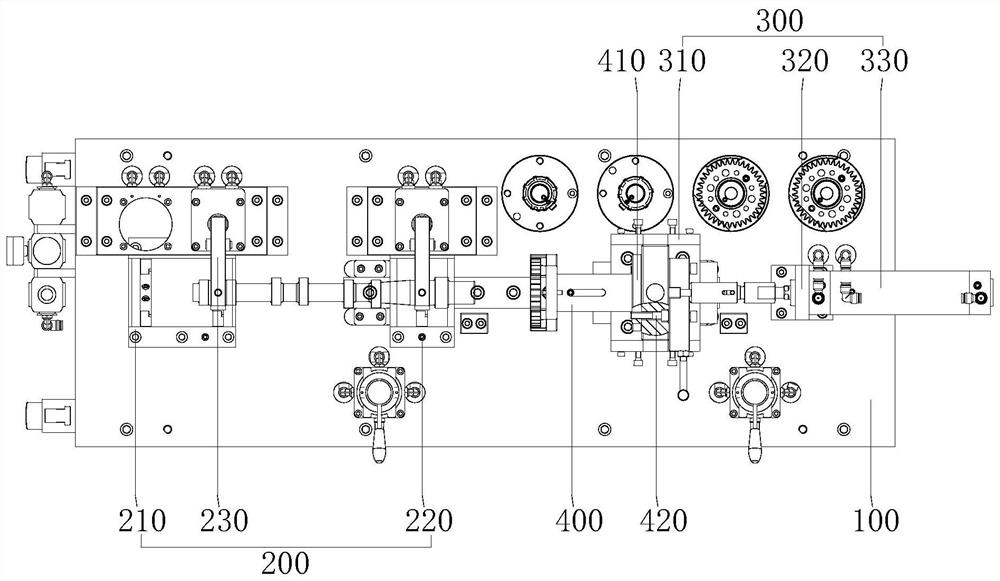

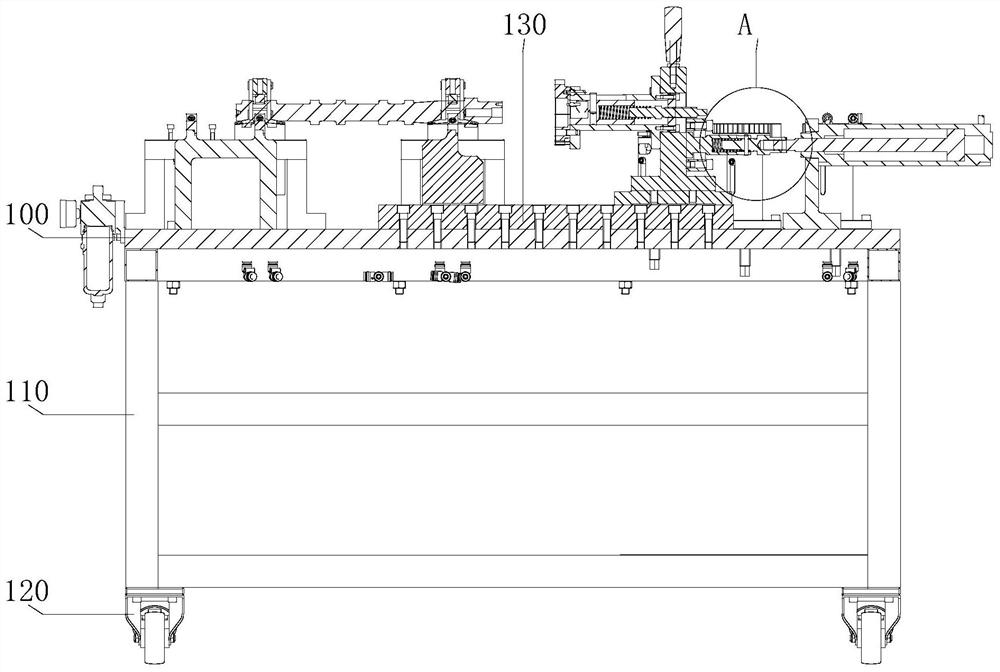

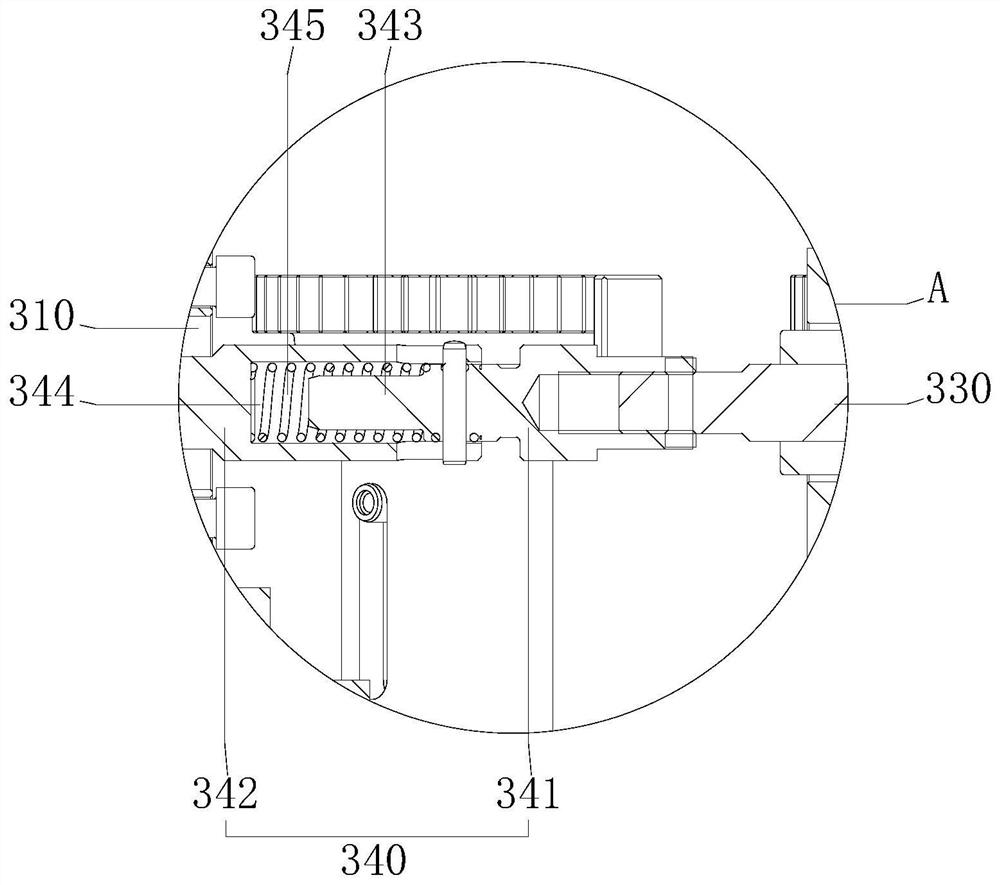

[0032] see Figure 1-4 , the present invention provides a high-precision camshaft timing gear and signal disc press assembly tooling, including a base plate 100 , a clamping mechanism 200 , a moving mechanism 300 and a pressure head 400 .

[0033] Among them, the clamping mechanism 200 is arranged on the surface of the bottom plate 100, and the clamping mechanism 200 is used to clamp the shaft, which reduces the possibility of the shaft moving during the press-fitting process and makes the press-fitting more stable and accurate. The moving mechanism 300 It is used to move the indenter 400, so that the indenter 400 and the extruded workpiece can be pressed into the workpiece. The indenter 400 and the moving mechanism 300 are connected in a detachable manner, which is convenient for disassembling the indenter 400. Operators can install indenters 400 of different specifications according to the specifications of camshaft timing gears, signal discs and other workpieces, reducing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com