Yarn end-forming device of yarn reeling machine

A technology of a spinning device and a spinning machine, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and processing of thin materials, can solve the problems of device structure and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is a specific embodiment of a spin-in device for a spinning machine of the present invention in conjunction with the illustrations. The embodiment is only an illustration of the present invention and does not constitute a limitation to the claims of the present invention. The unmentioned parts of the present invention are applicable to the present invention have technology.

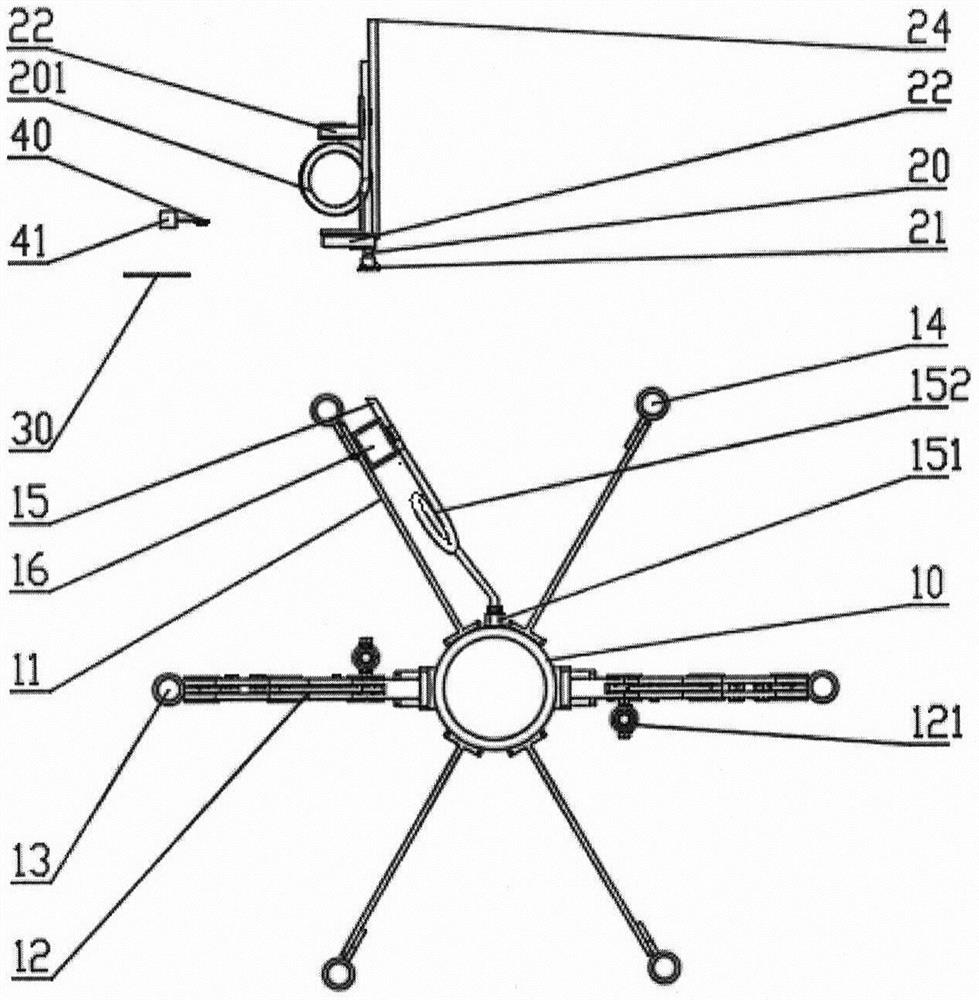

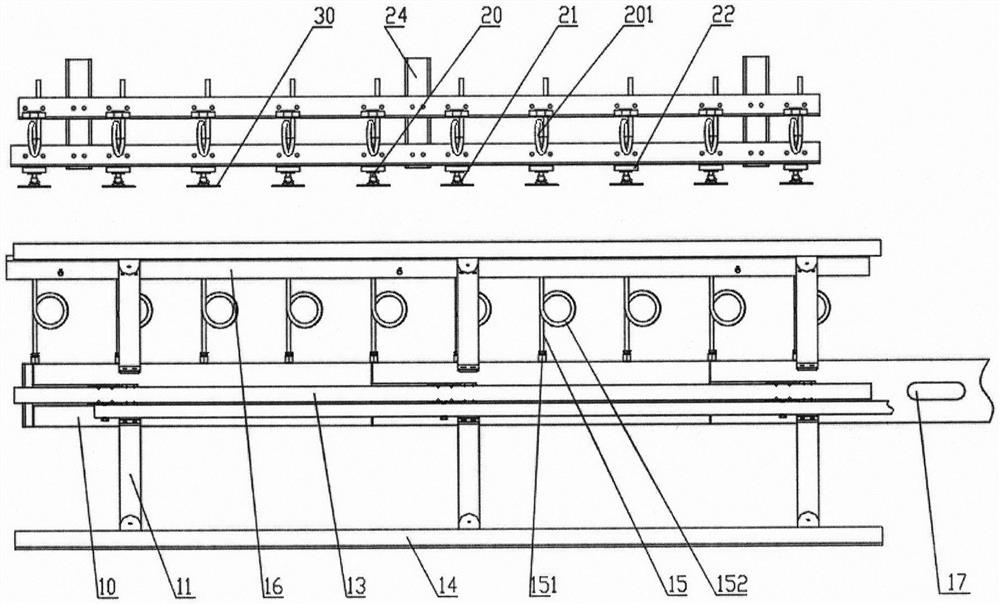

[0020] A kind of embodiment of spinning machine spinning-in device of the present invention (such as Figure 1-2 shown):

[0021] The yarn frame shaft 10 of the spinning machine in this embodiment is a hollow shaft, and is a sealed structure except for the yarn frame suction port 17 and the air nozzle 151 opened on the shaft. The yarn frame suction port 17 is a hole opened outside the yarn frame shaft 10 for connecting Negative pressure suction device, for example, adopts a rubber negative pressure interface piece similar in shape to the yarn frame suction port 17 to introduce negati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com