Measurement gauge combination and using method thereof

A technology for checking fixtures and locking screws, which is used in manufacturing tools, measuring/indicating equipment, metal processing equipment, etc., and can solve the problems of deviation from the center of rotation, deviation of the second guide block from the original design position, and out of tolerance of the workpiece.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

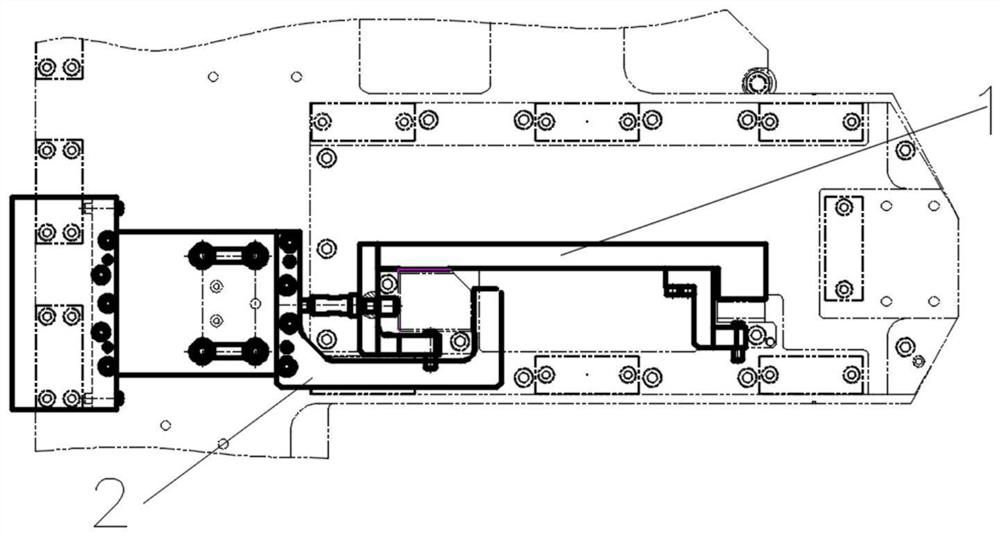

[0053] Such as figure 1 As shown, a combination of measuring and checking tools includes a size checking tool 1 and a parallel checking tool 2. The abutment bolt and the support nail 113 are arranged coaxially, and the abutting position of the abutment bolt contacts the first positioning block 111 .

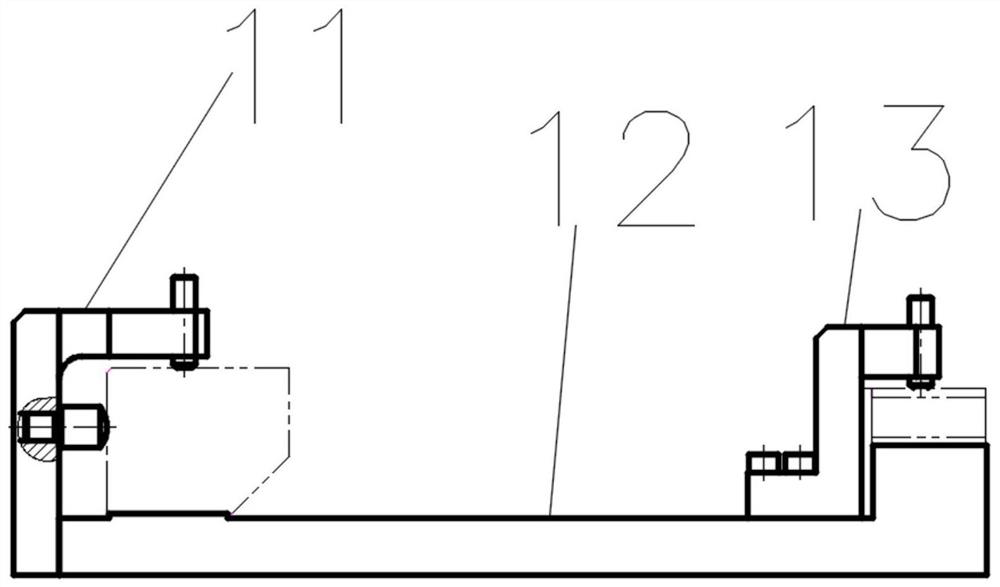

[0054] Such as figure 2 As shown, the dimension inspection tool 1 includes a positioning part 11 , an alignment part 12 and a locking part 13 , and the positioning part 11 and the locking part 13 are respectively provided at both ends of the alignment part 12 .

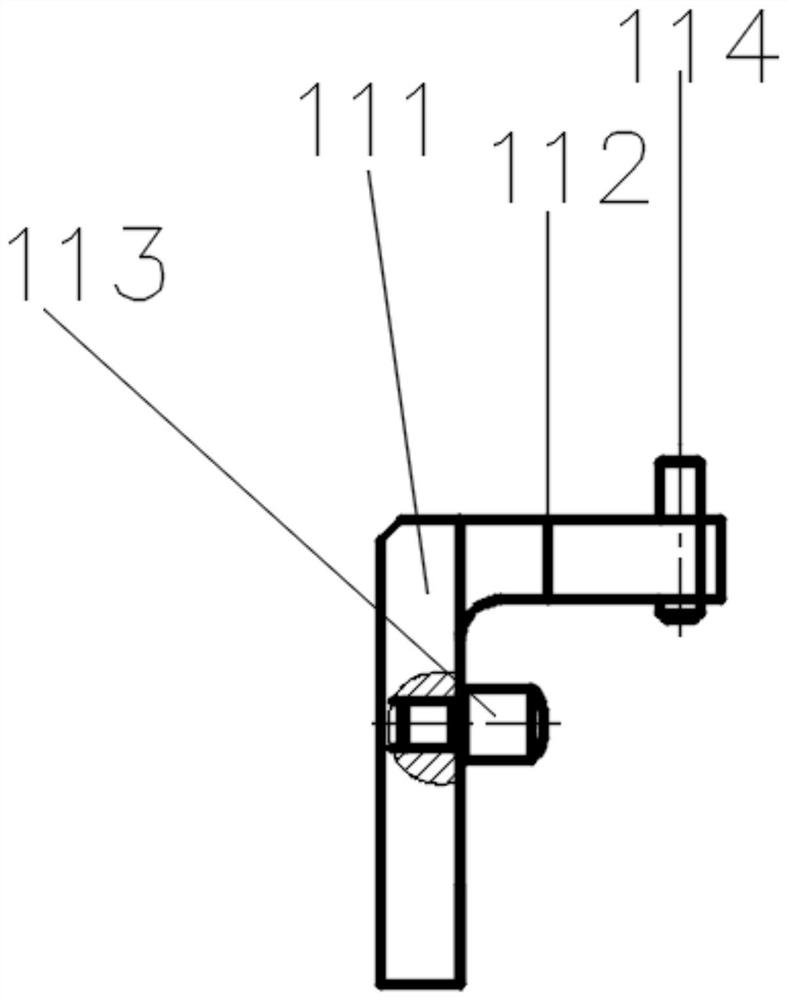

[0055] Such as image 3 As shown, the positioning part 11 includes a first positioning block 111, a second positioning block 112, a supporting nail 113 and a first locking screw 114, one end of the first positioning block 111 is vertically connected with one end of the second positioning block 112, and the first positioning part 11 The other end is vertically connected to the alignment part 12, the first positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com