Detection and auxiliary packaging device for EVA blister plates

A technology of blister board and auxiliary layer, which is applied in the directions of packaging, packaging protection, transportation and packaging, etc., and can solve problems affecting user experience, damage to loaded items, loss of production capacity of manufacturers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

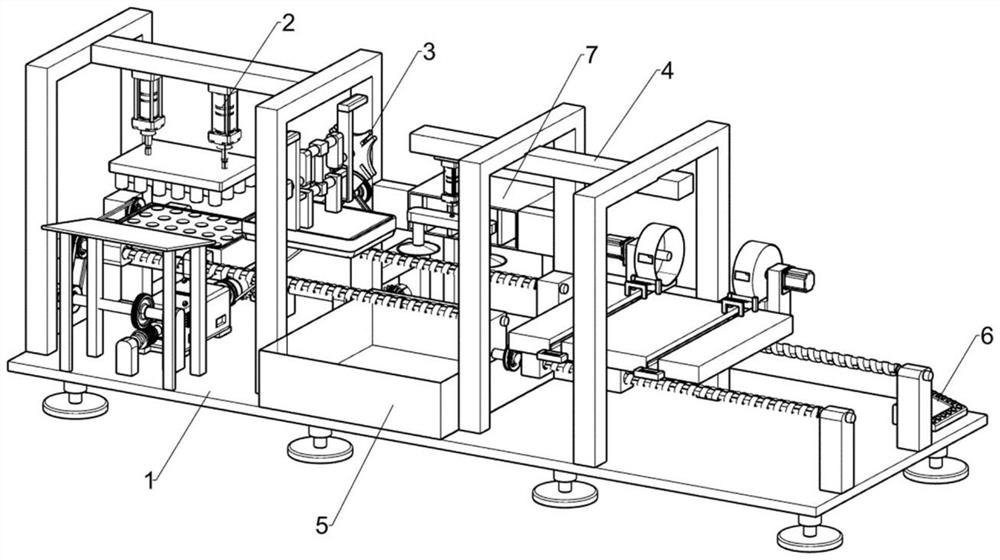

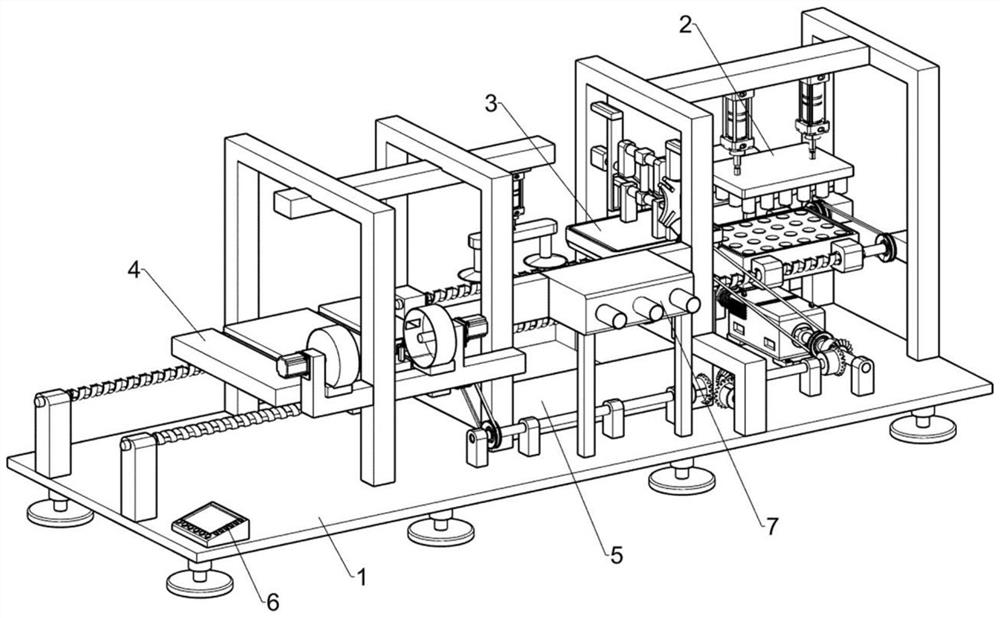

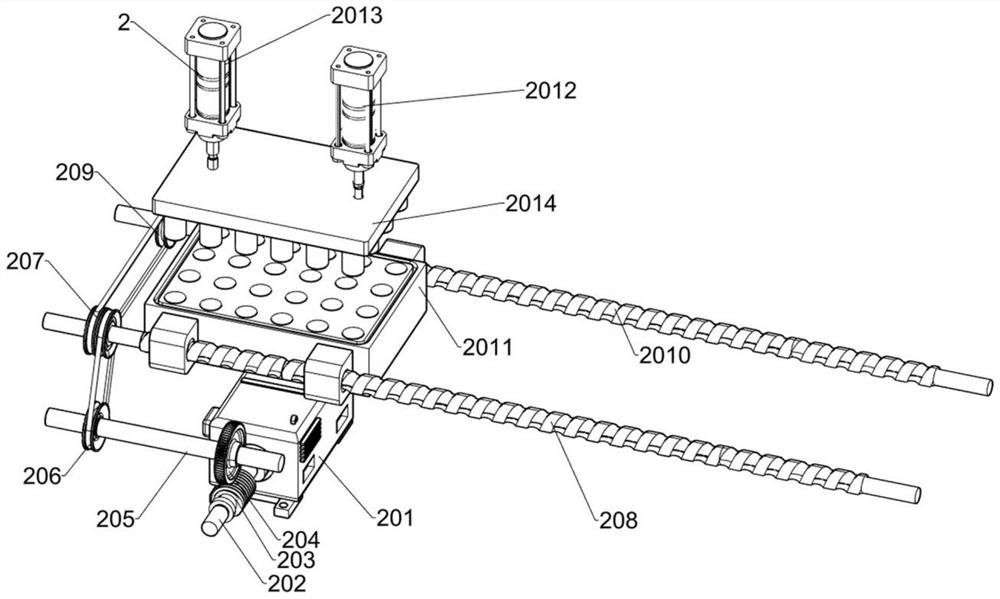

[0028] A detection and auxiliary packaging device for EVA blister board, such as Figure 1-9 As shown, it includes a support chassis 1, a quality inspection system 2, an edge trimming system 3, an auxiliary stacking and packing system 4, a first collection box 5, a controller 6 and a bellows 7; 2. Trimming system 3 and auxiliary stacking and packaging system 4; supporting base frame 1 is connected with first collection box 5; supporting base frame 1 is connected with controller 6; supporting base frame 1 is welded with bellows 7; quality inspection system 2 is connected with the trimming system 3; the quality inspection system 2 is connected with the auxiliary stacking and packaging system 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com