Window glass edge removing and scratching equipment

A scratch and glass technology, which is applied in the field of window glass edge removal and scratch equipment, can solve the problems of manpower time-consuming, low efficiency, difficult operation, etc., and achieve the effect of improving work efficiency and facilitating loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

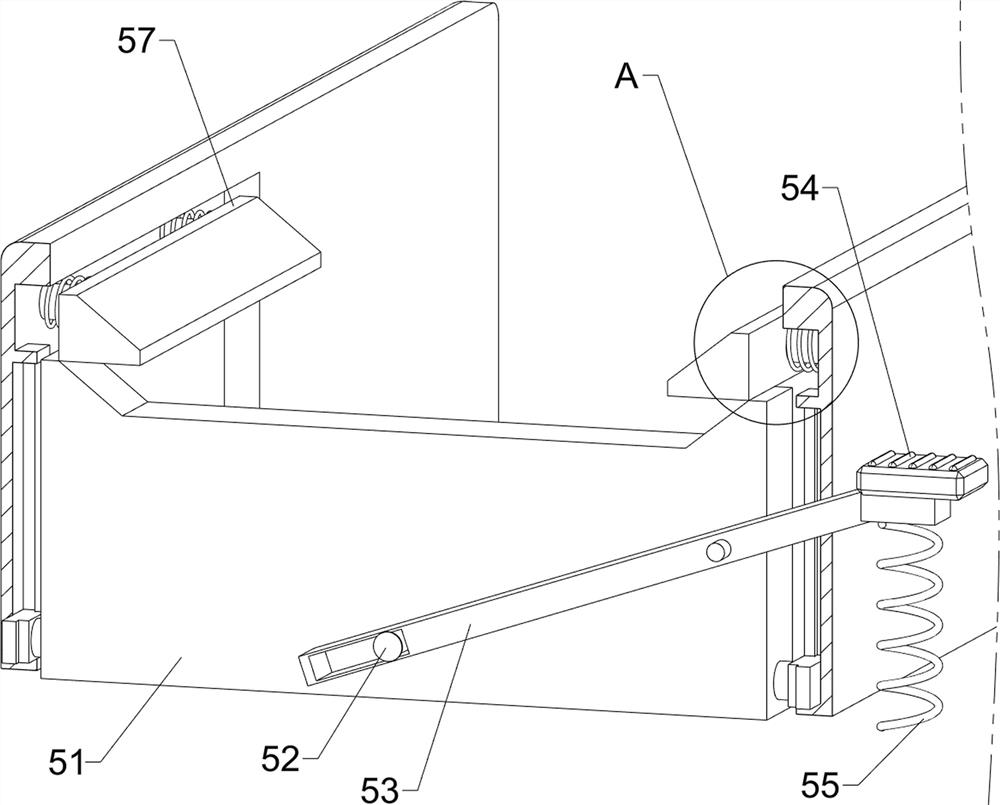

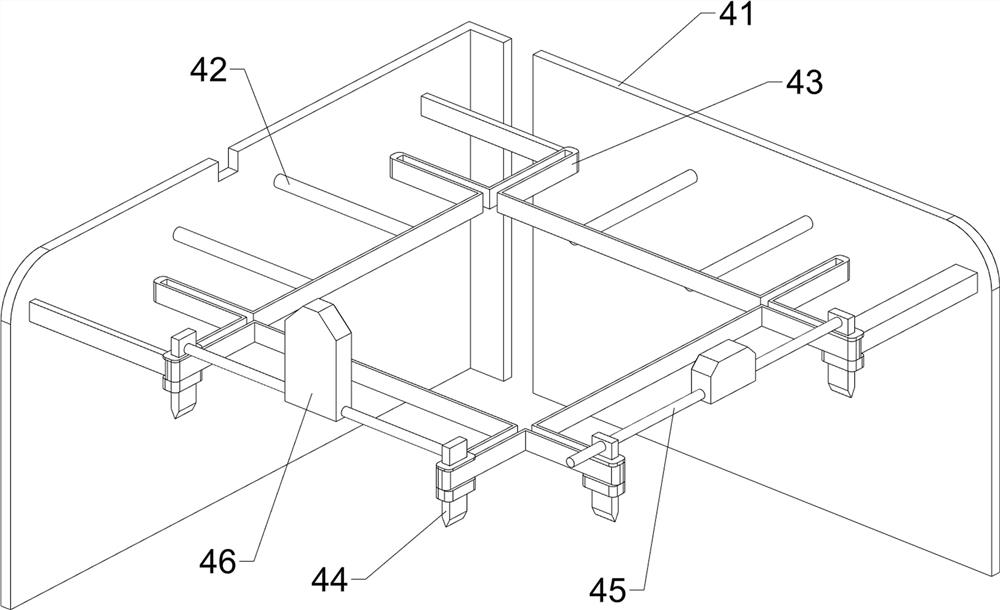

[0031] A kind of window glass edge scraping equipment, such as figure 1 , figure 2 , image 3, Figure 4 and Figure 5 As shown, it includes a base 1, a support frame 2, a fixed assembly 3, a scratch assembly 4 and a rising assembly 5, a support frame 2 is provided in the middle of the upper part of the base 1, a fixed assembly 3 is provided between the front and rear sides of the support frame 2, and the base 1 is provided with a scratch assembly 4 on the left side of the upper part, and a lifting assembly 5 is provided at the upper left part of the base 1.

[0032] When the user needs to remove the edges and scratches on the window glass, first put the glass on the fixed assembly 3, step on the lifting assembly 5, and drive the scratch assembly 4 to move, so that the glass is removed and scratched, and then the glass is removed , Unified collection, to achieve the effect of automatically removing scratches for the glass.

[0033] The fixing assembly 3 includes a first ...

Embodiment 2

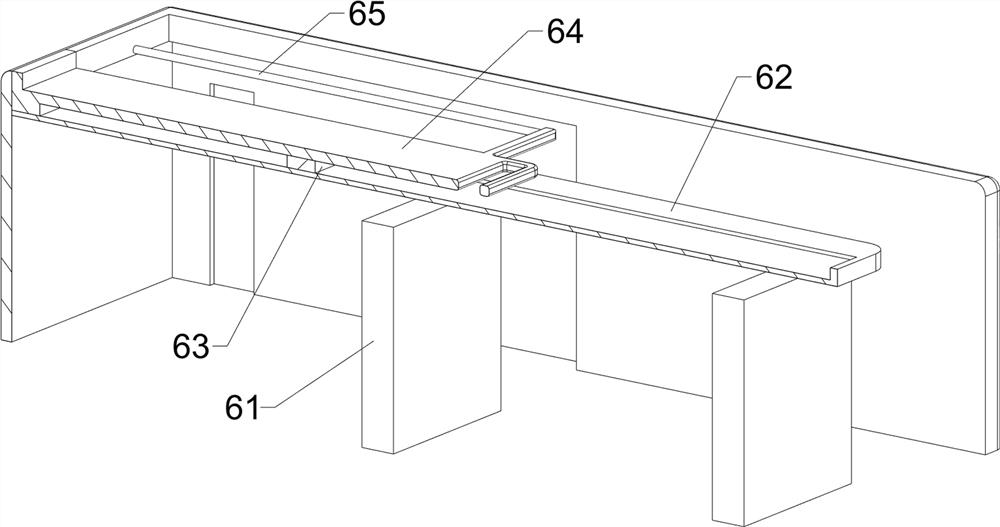

[0040] On the basis of Example 1, such as Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, an auxiliary discharge assembly 6 is also included, and the auxiliary discharge assembly 6 includes a fourth support plate 61, a second slide rail 62, a slider 63, a movable plate 64 and a fourth connecting rod 65, and the upper right side of the base 1 and the middle are connected with a fourth support plate 61, the upper side of the fourth support plate 61 is connected with a second slide rail 62, the left side of the second slide rail 62 is connected with the left side of the support frame 2, and the upper side of the second slide rail 62 Slide block 63 is connected to the side slide type, and movable plate 64 is connected to the upper side of slide block 63, and the fourth connecting rod 65 is connected symmetrically front and rear on the right side of movable plate 64, and the fourth connecting rod 65 is slidingly connected to the left side of support frame ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap