Defrosting mechanism of refrigeration equipment

A technology of refrigeration equipment and compressors, which is applied in refrigerators, defrosting, refrigeration components, etc., which can solve the problems of reduced cooling effect, inconvenient large-area defrosting, and low defrosting efficiency, so as to achieve convenient distance adjustment and improve defrosting effect, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following is attached Figure 1-4 The application is described in further detail.

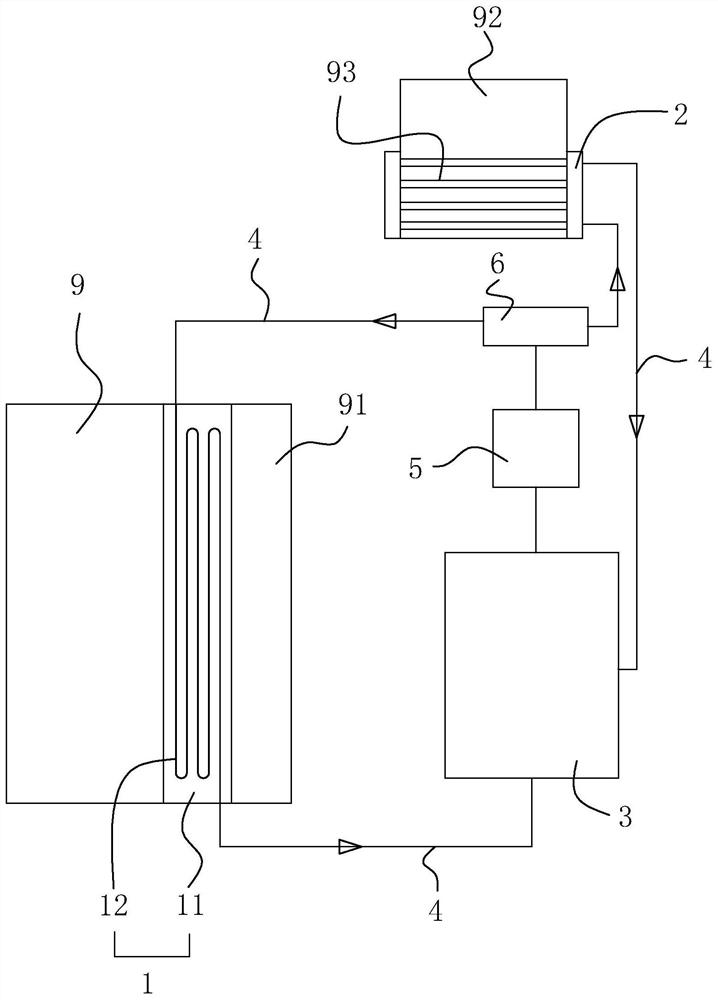

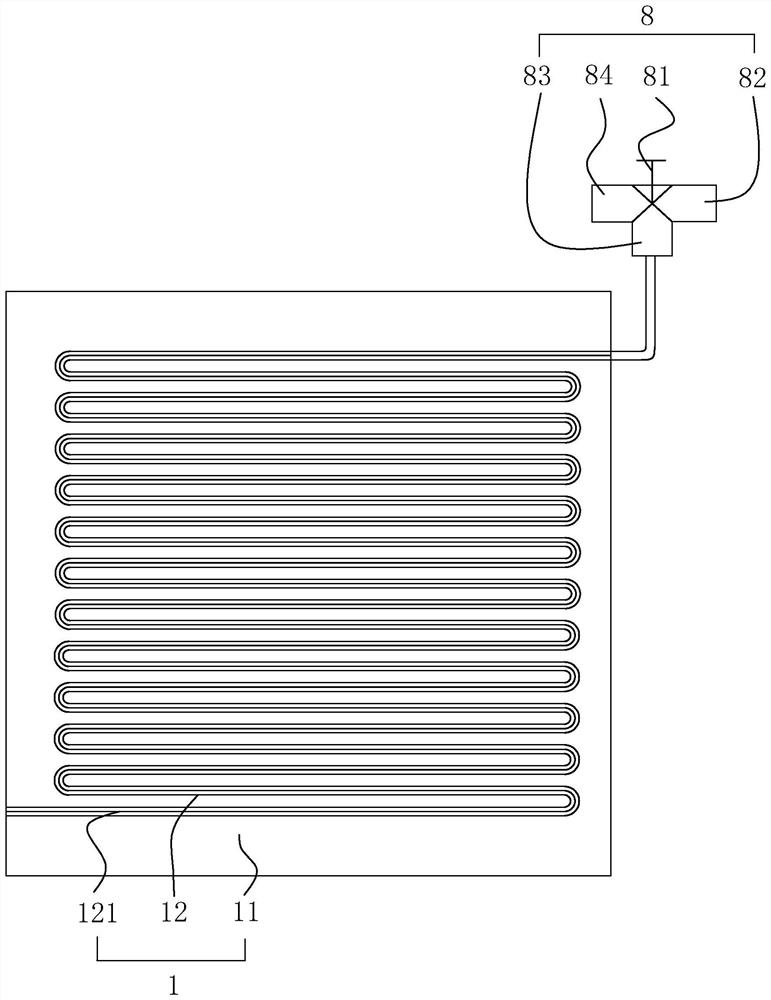

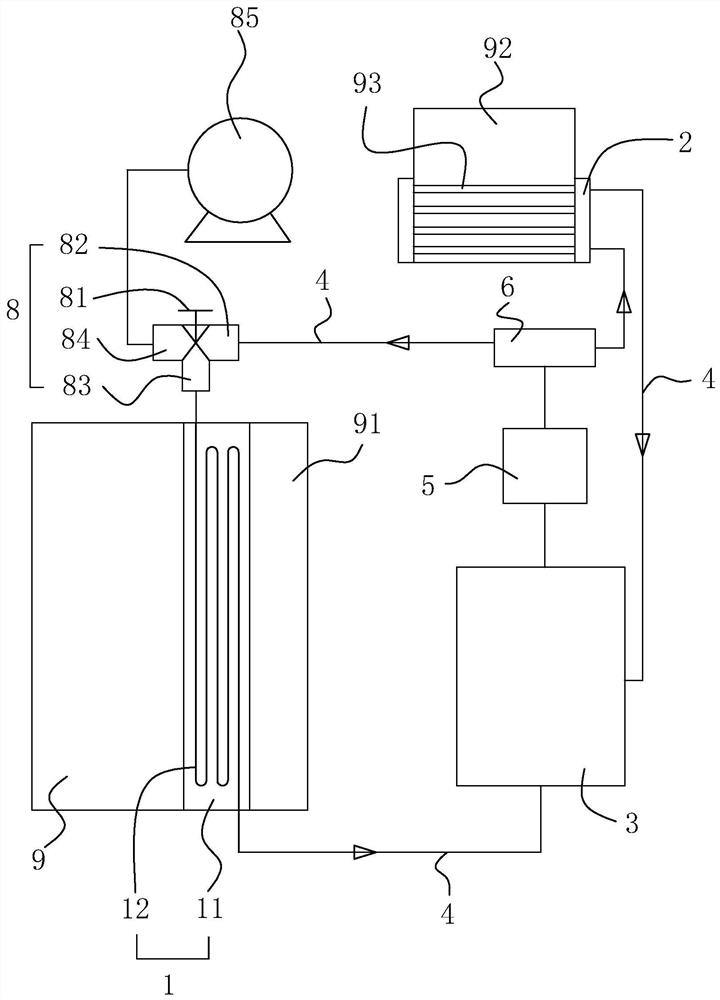

[0037] The refrigerating equipment mainly includes a compressor 92, an evaporator 9, a condenser, a refrigerant storage tank, a filter, and an expansion valve, in which each component is connected through a liquid infusion pipe, and the refrigerant is compressed by the compressor 92 to make the refrigerant flow in the evaporator 9 and The heat between the condenser and the outside air is better, so that the evaporator 9 absorbs heat to the outside to achieve the cooling effect, and the condenser emits heat to the outside to achieve the heating effect, wherein the evaporator 9 and the condenser are equipped with a fan 91. 91 enhances the air flow at the position of the evaporator 9 and the condenser, thereby improving the heat exchange effect and efficiency with the outside world, wherein the surface of the evaporator 9 is relatively low in temperature, and external water vapor is eas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com