Cooling fin mounting device

A technology for installing devices and heat sinks, which is applied in the direction of modification through conduction heat transfer, cooling/ventilation/heating transformation, electrical components, etc., which can solve problems such as PCB heat sink component damage, so as to solve component damage and avoid pain Discomfort, guaranteed precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

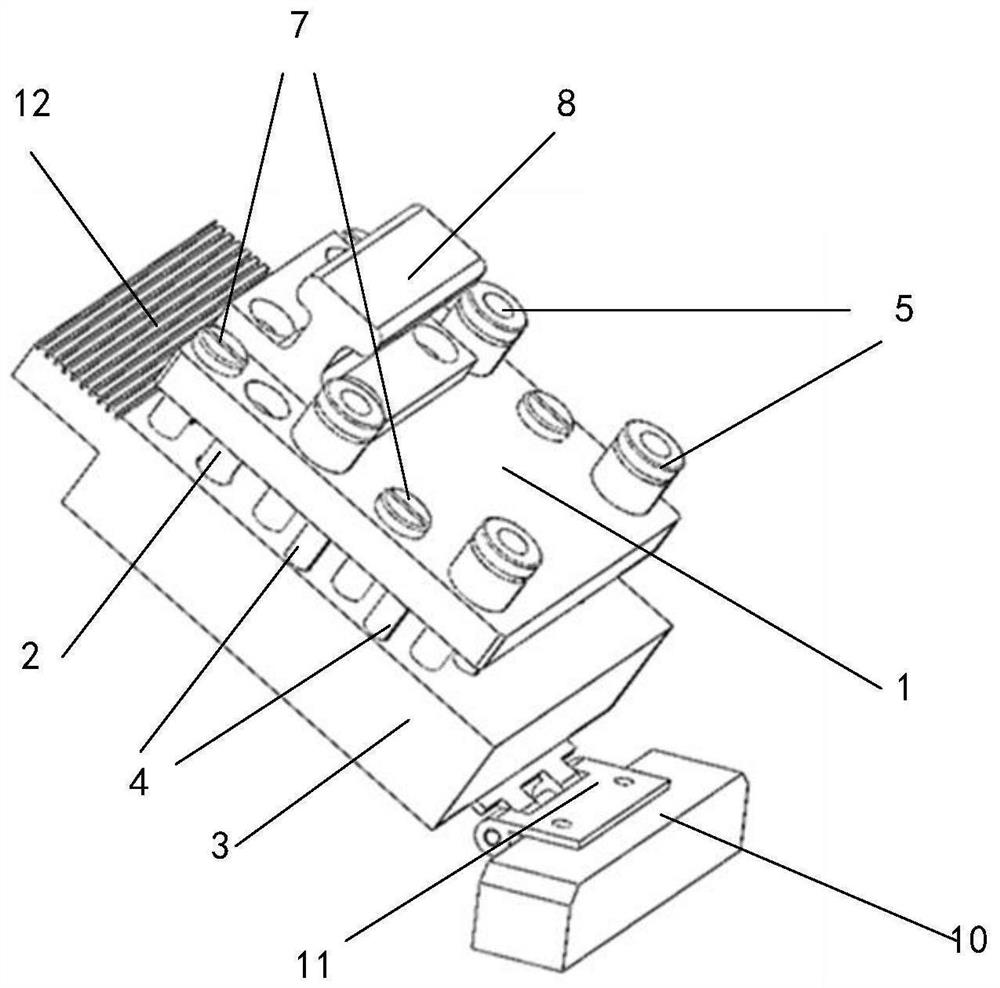

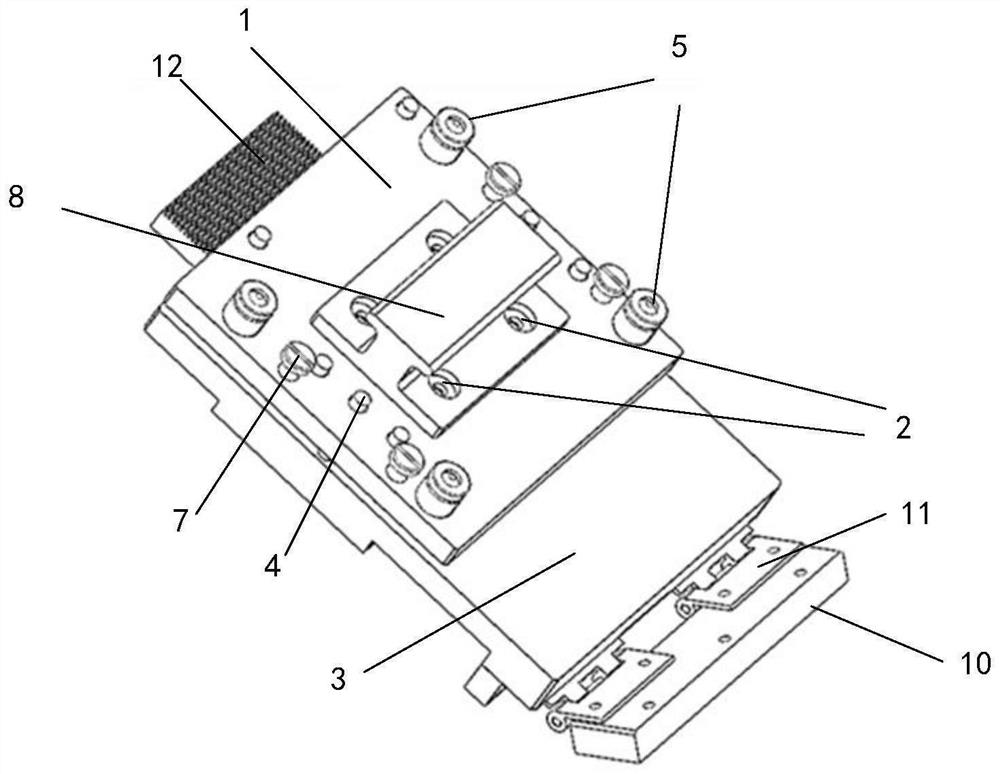

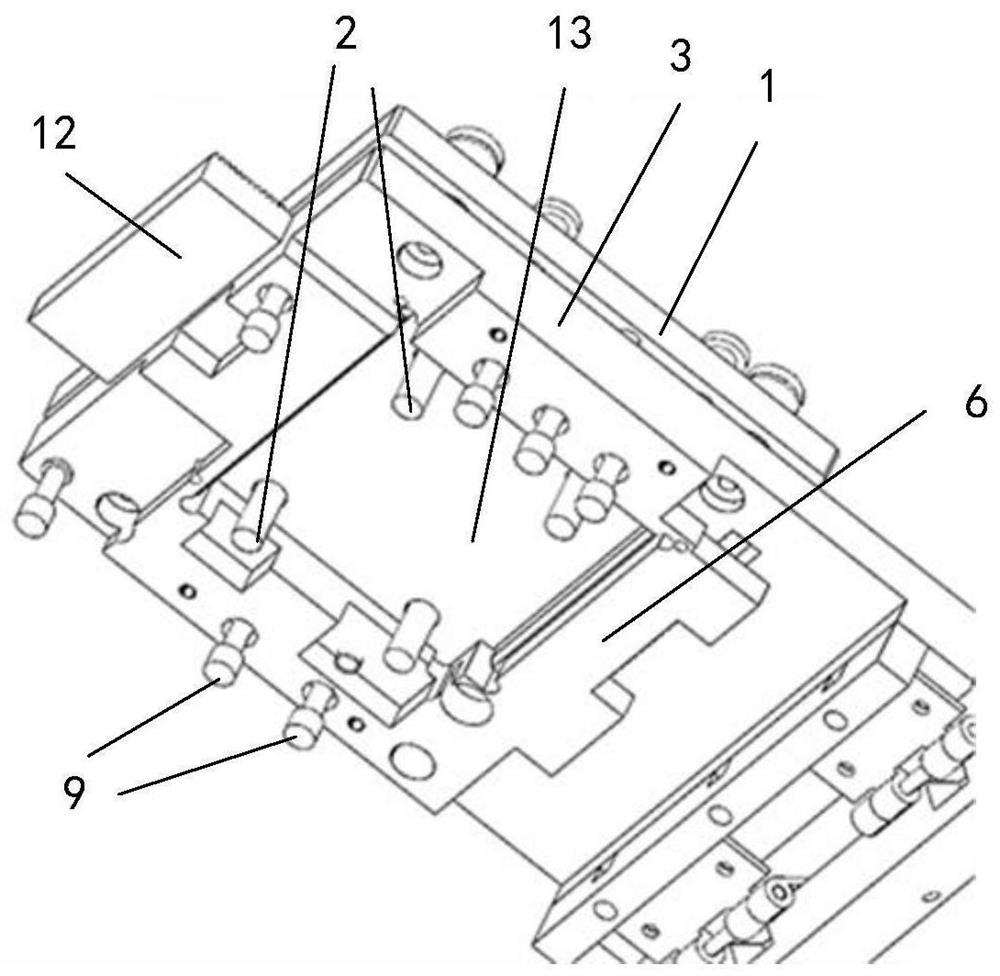

[0033] The heat sink mounting device provided by the embodiment of the present invention is used to install the heat sink 14 of the PCB, such as Figure 4 and Figure 5 As shown, there are two types of heat sinks, one is a heat sink with two fixed plugs, and the other is a heat sink with four fixed plugs. Such as Figure 1 to Figure 3 As shown, the cooling fin installation device includes a pressing plate 1 , a pressing column 2 , a bin plate 3 , a spring 4 and a bearing 5 . in, figure 1 It is a heat sink mounting device with 2 fixed plugs, figure 2 and image 3 It is a heat sink mounting device with 4 fixed plugs. Pressing plate 1 and silo plate 3 are flexibly connected through spring 4 and bearing 5, and the relative distance between pressing plate 1 and silo plate 3 can be changed through compression and rebound of spring 4. The setting of bearing 5 ensures that Smooth and fluid linear motion. The pressing plate 1 is provided with a plurality of pressing columns 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com