A heat sink installation device

A technology for installing devices and heat sinks, which is used in cooling/ventilation/heating transformation, modification by conduction heat transfer, electrical components, etc. It can solve problems such as damage to PCB heat sink components, so as to solve component damage and ensure accuracy. the effect of reducing the repair rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

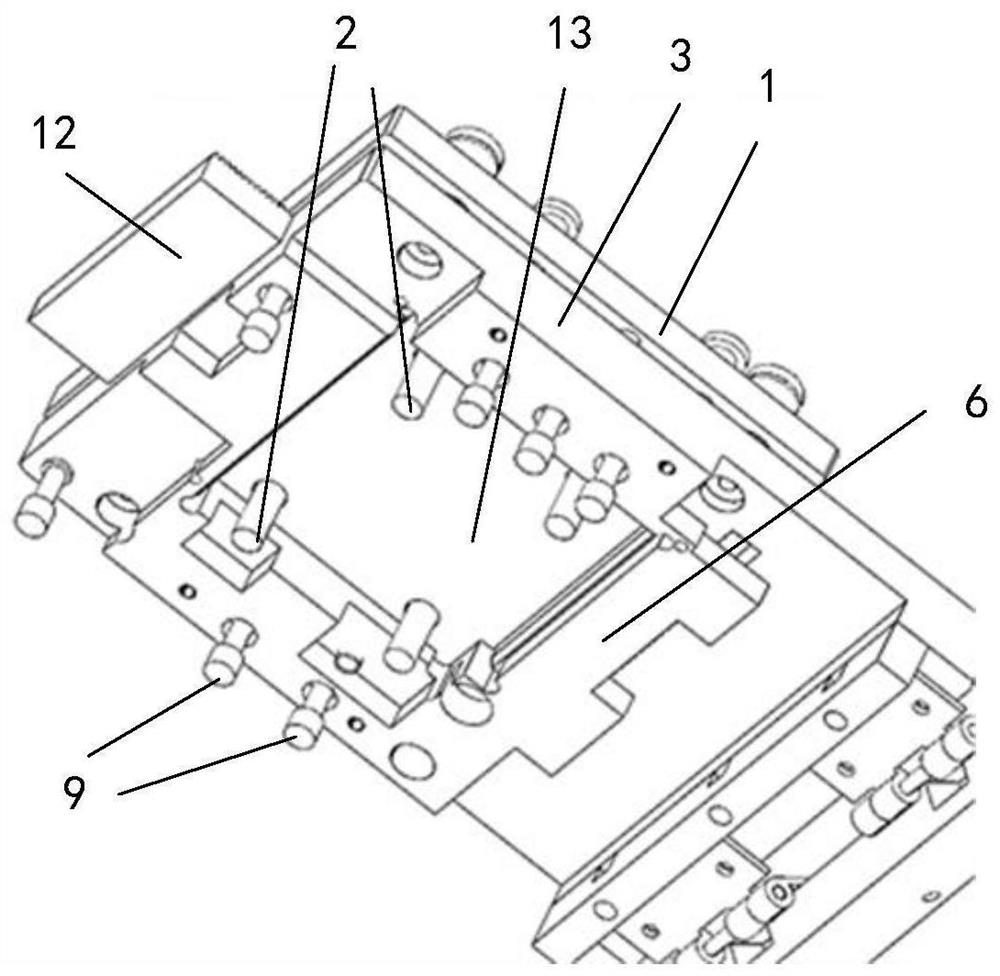

[0036] In a possible implementation, the locking slider 6 is provided with a guide slope. Guided slopes are provided for easy heat dissipation

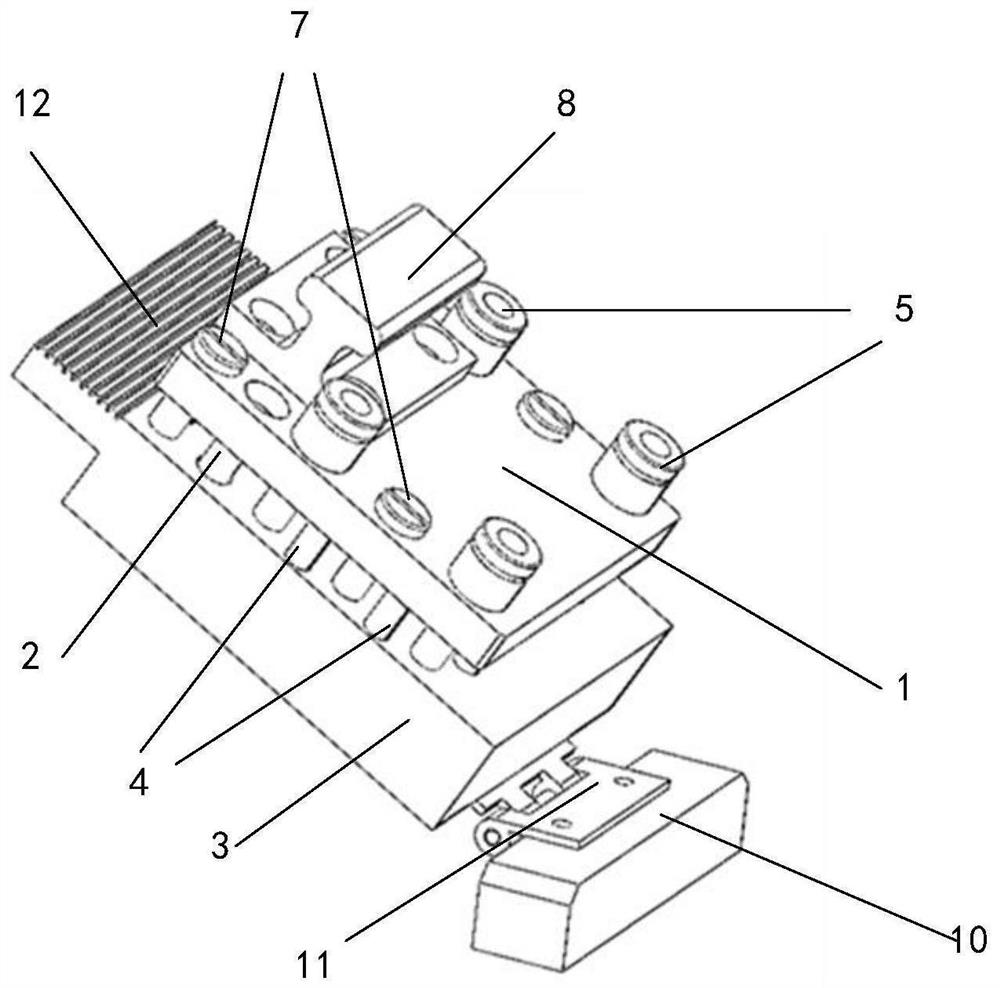

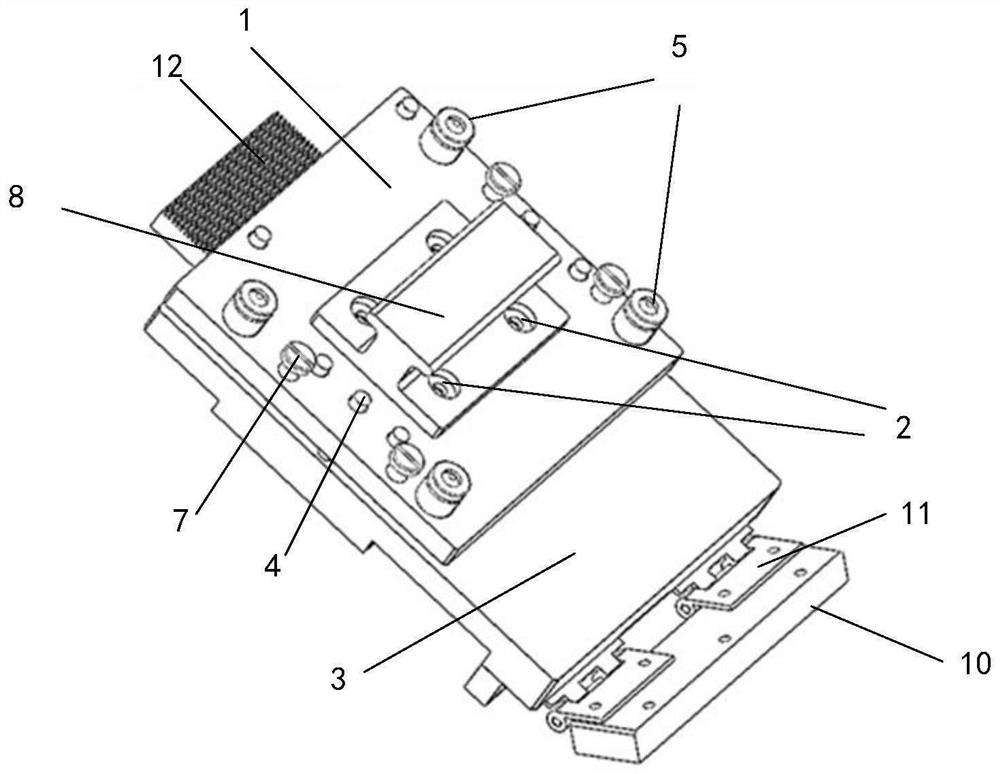

[0038] In a possible implementation, the top surface of the pressing plate 1 is provided with a pressing handle 8. Operators can press

[0039] In a possible implementation, the number of the pressing columns 2 is 2 or 4. As shown in Figures 4 and 5, the most common

[0040] In a possible implementation, the bearing 5 is a linear bearing. Linear bearings are in point contact with the shaft because of their bearing balls.

[0042] In a possible implementation, the heat sink mounting device provided in the embodiment of the present invention further includes a blocking block

[0043] In a possible implementation manner, a hand-held handle 12 is provided on one side of the silo plate 3 . Set the hand grip 12, increase

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com