Tamping device vibration component with cooling device and corresponding cooling method

A technology for cooling devices and vibrating components, which is applied in bearing cooling, bearing components, roads, etc., can solve the problems of unsuitable cooling of vibrating components of tamping devices, and achieve high-frequency operation, high engineering application value, and effective cooling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

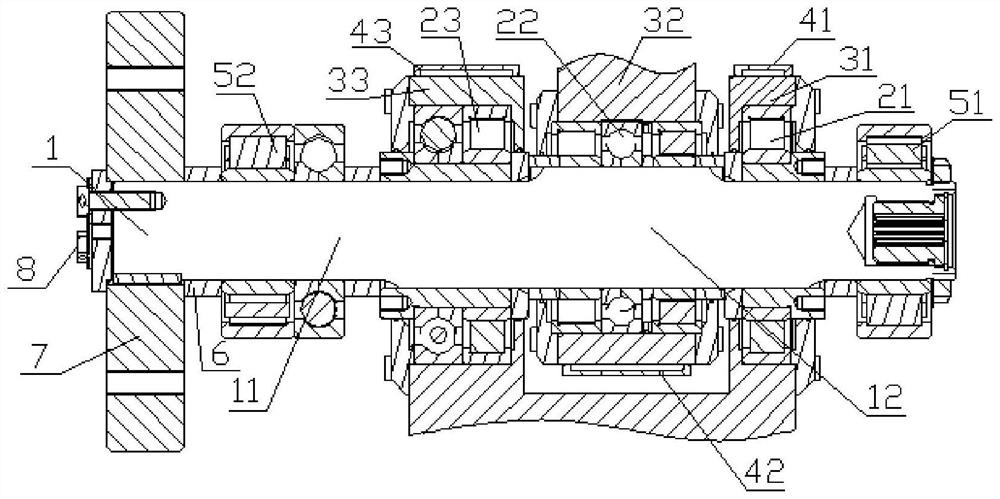

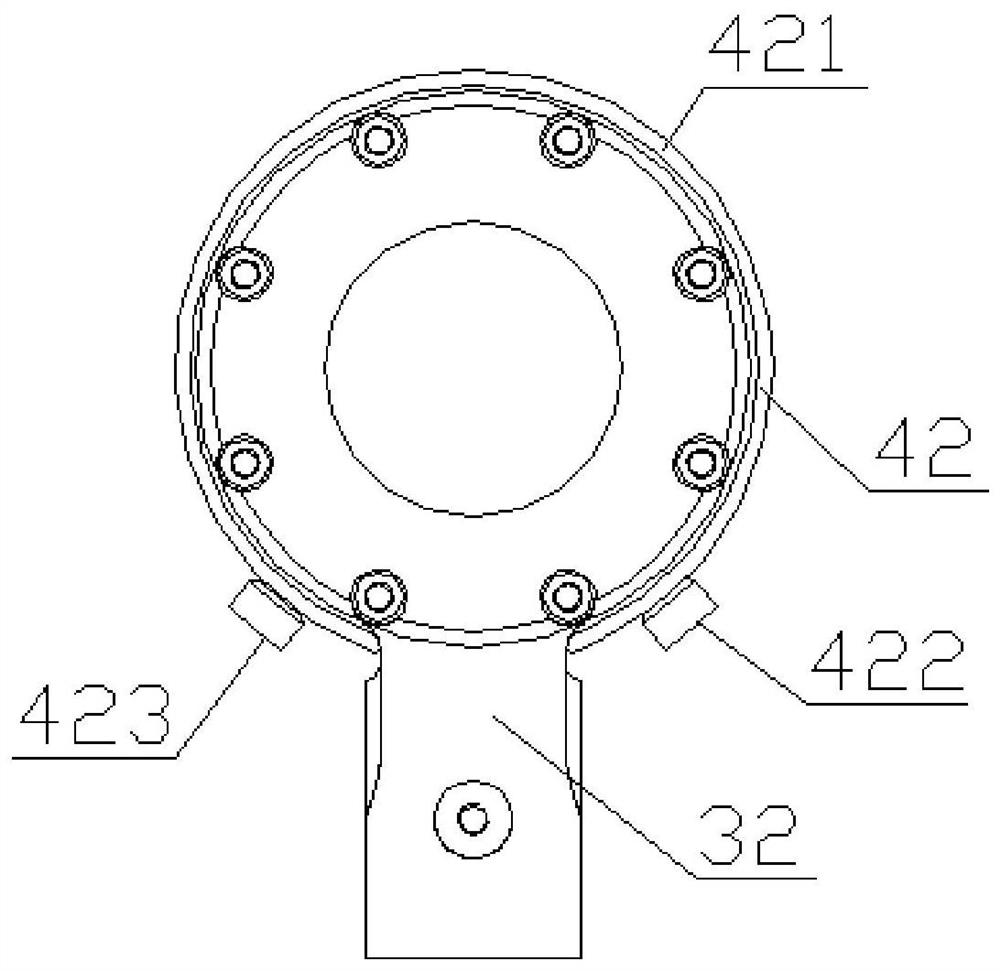

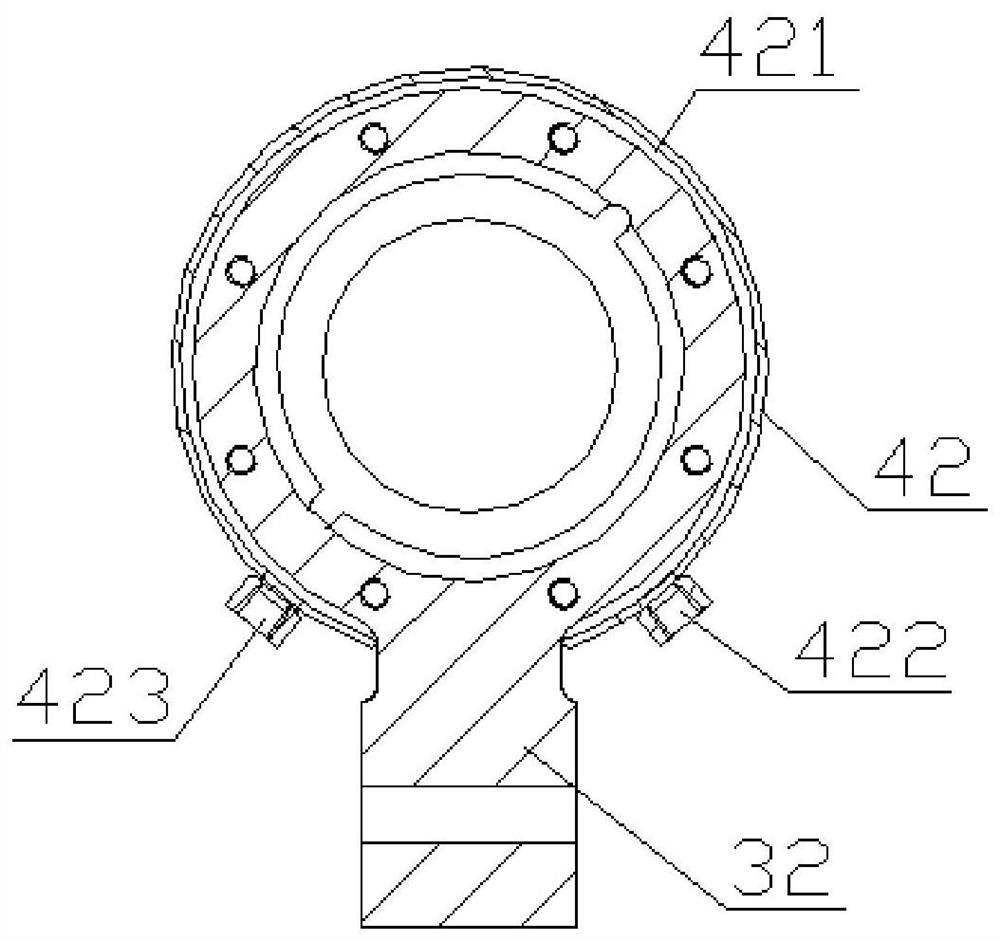

[0028] Embodiment one: if figure 1 As shown, a vibrating part of a tamping device containing a cooling device includes an eccentric vibrating shaft 1, a vibrating bearing, a vibrating bearing sleeve and a cooling device, the inner side of the vibrating bearing is connected to the eccentric vibrating shaft 1, and the outer side of the vibrating bearing is connected to the The vibrating bearing sleeve is connected with a cooling device on the outer side of the vibrating bearing sleeve. The cooling device includes a cooling channel, the two ends of the cooling channel are provided with a cooling inlet and a cooling outlet, the cooling channel is preferably in the form of a channel, the cooling inlet is preferably equipped with an inlet joint, and the cooling outlet is preferably equipped with an outlet joint, Preferably, the cooling channel fully covers the vibration bearing sleeve, so as to increase the heat transfer area and enhance the cooling effect.

[0029] The eccentric v...

Embodiment 2

[0036] Embodiment two: if Figure 5 As shown, only cylindrical roller bearings are used for the vibrating bearing and supporting bearing in this embodiment, and this embodiment is suitable for the case where the vibrating shaft component only bears radial force. All the other structures are the same as in Embodiment 1.

Embodiment 3

[0037] Embodiment 3: The four-point angular contact ball bearings and cylindrical roller bearings used together in Embodiment 1 are replaced by tapered roller bearings used in pairs. This embodiment can also carry axial force and radial force at the same time. force. All the other structures are the same as in Embodiment 1.

[0038] A method for cooling the vibrating part of a tamping device, which is implemented by any preferred solution contained in the above-mentioned embodiments, and the specific solution is as follows: a cooling device is arranged on the outer periphery of the high-temperature part of the vibrating shaft part of the tamping device, and the cooling device It at least includes a cooling channel, a cooling inlet, and a cooling outlet. The coolant is injected from the cooling inlet, and the coolant flows through the cooling channel and flows out from the cooling outlet, thereby taking away the heat of the high-temperature part and realizing the cooling of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com