Wind tower universal type temporary bracket

A general-purpose, temporary technology, applied in the direction of towers, building types, pillars, etc., can solve the problems of forced transformation or scrapping, dense holes, etc., and achieve the effect of enhancing strength and stability, strengthening strength and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

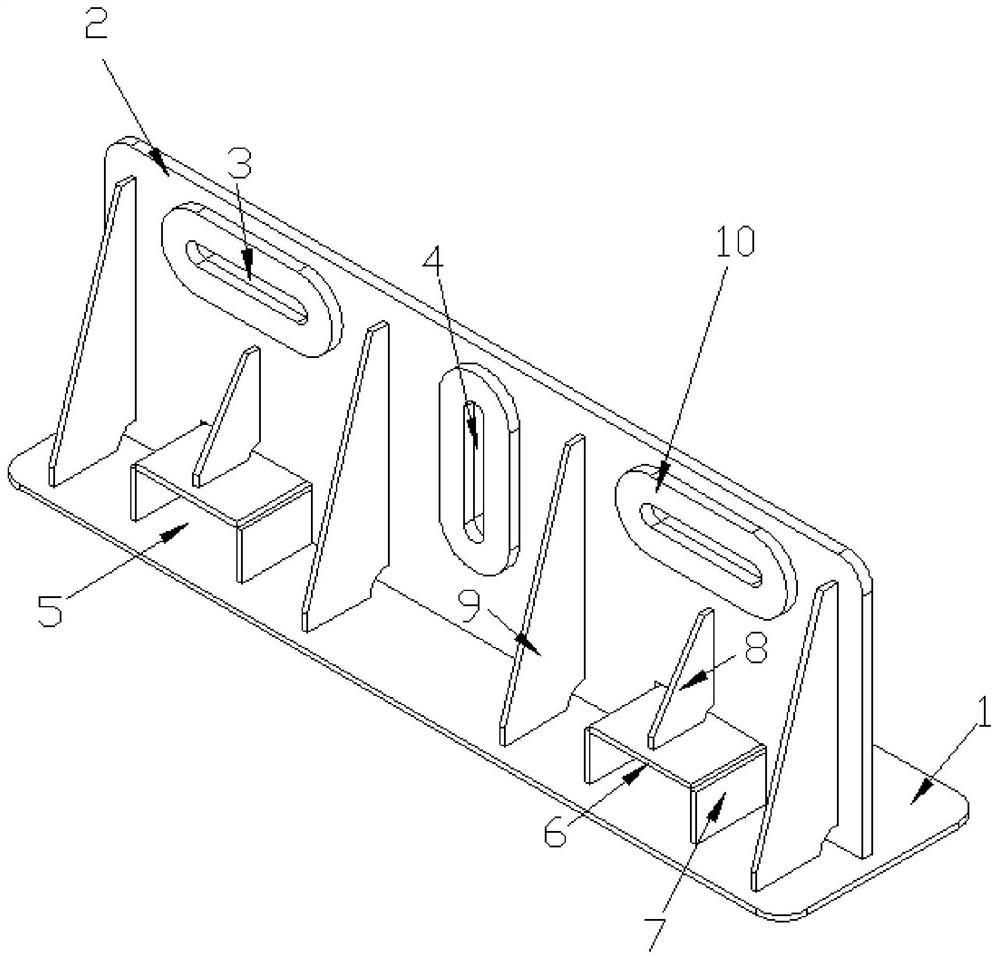

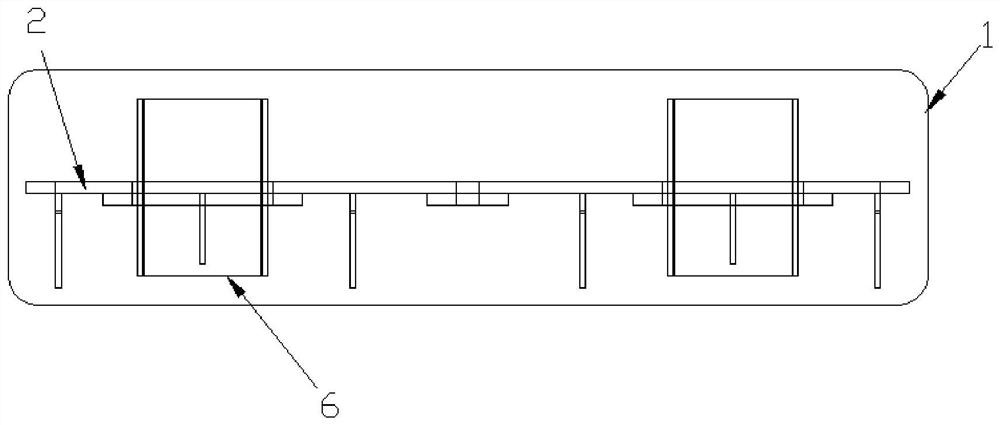

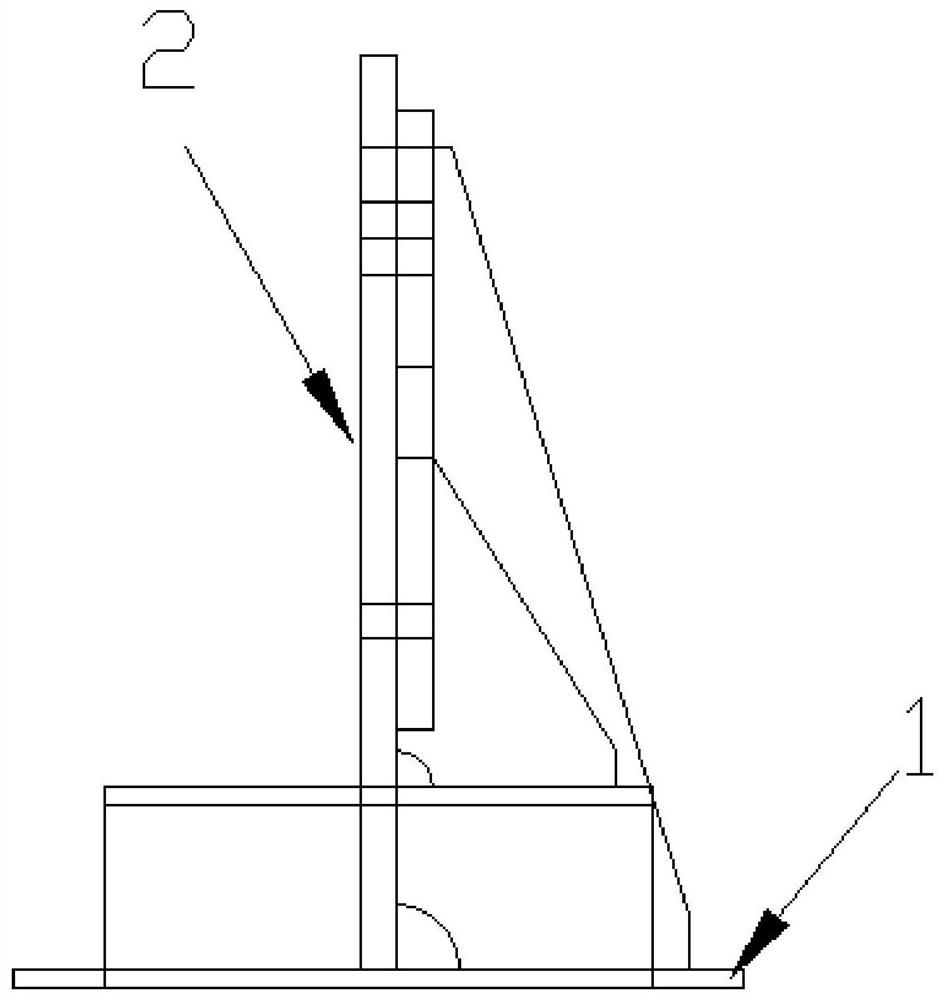

[0016] Such as Figure 1 to Figure 3 As shown, the present invention is a general-purpose temporary bracket for wind towers. 4 and the carrying bolt hole 3 are in the shape of a waist-shaped hole, and the temporary bracket is also provided with a forklift jack 5 for convenient forklift shoveling. The connecting plate 2 is arranged vertically, the bottom plate 1 is arranged horizontally, the connecting hole 4 is located between the two bearing bolt holes 3, and the forklift jack 5 is provided with two. The forklift jack 5 is a groove-shaped space formed by the transverse reinforcing plate 6 fixedly connected on the connection plate 2 and the vertical reinf...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap