Direct-plug direct-pull type floating connector

A floating connector and straight-pull technology, which is applied in the direction of connection, two-part connection device, and parts of the connection device, can solve the problems of large structural size and low reliability, achieve strong applicability, and improve mating quality , Improve the effect of mating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

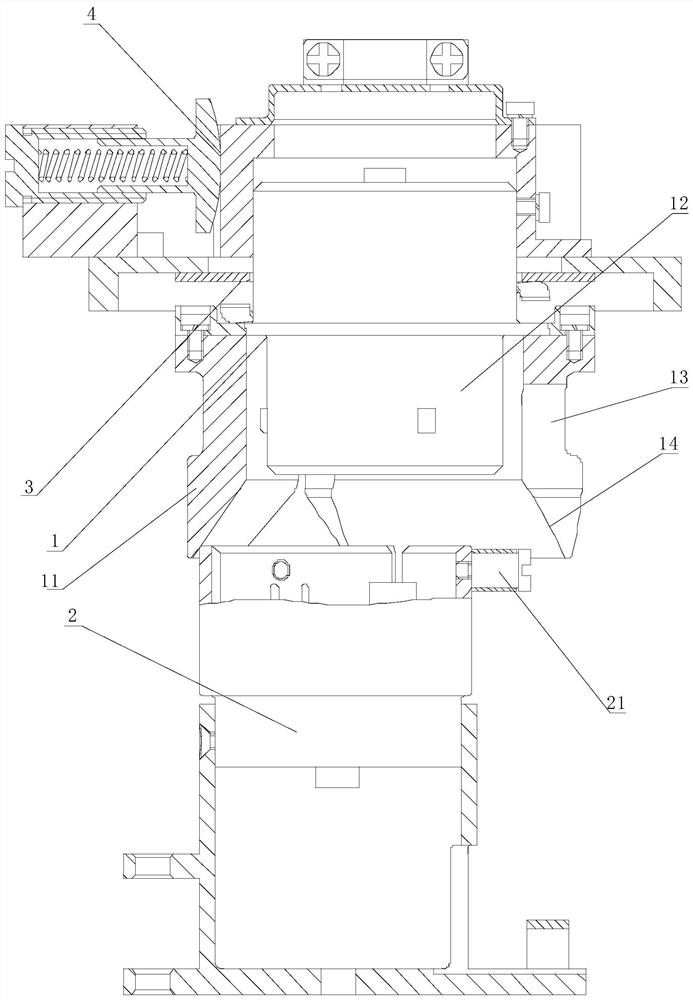

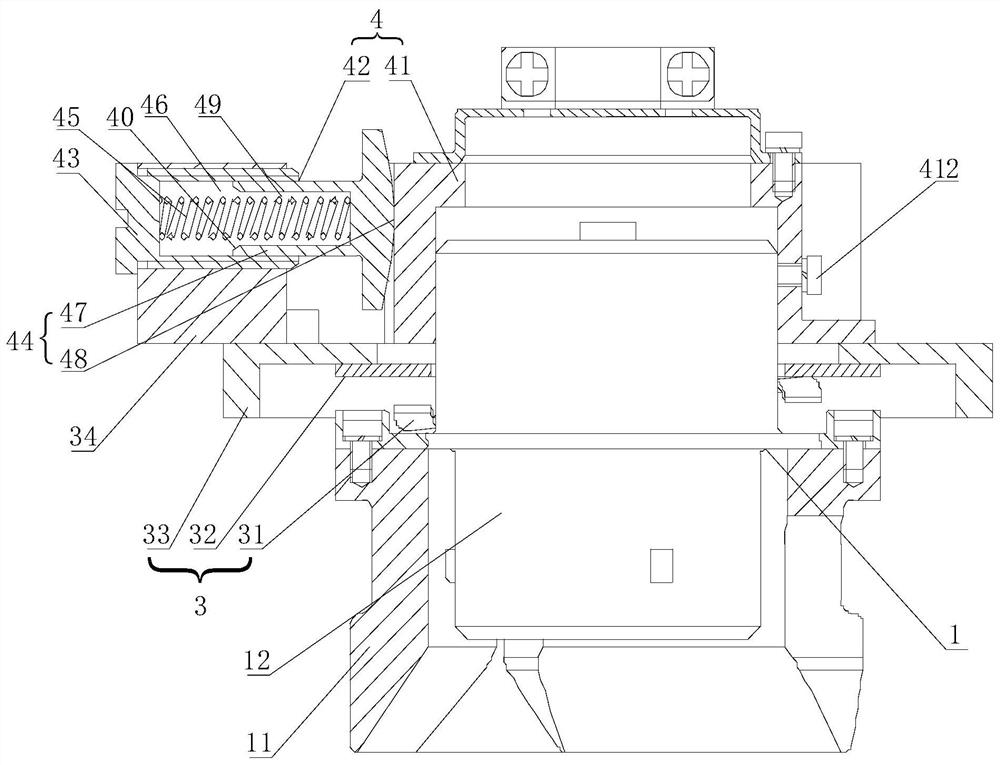

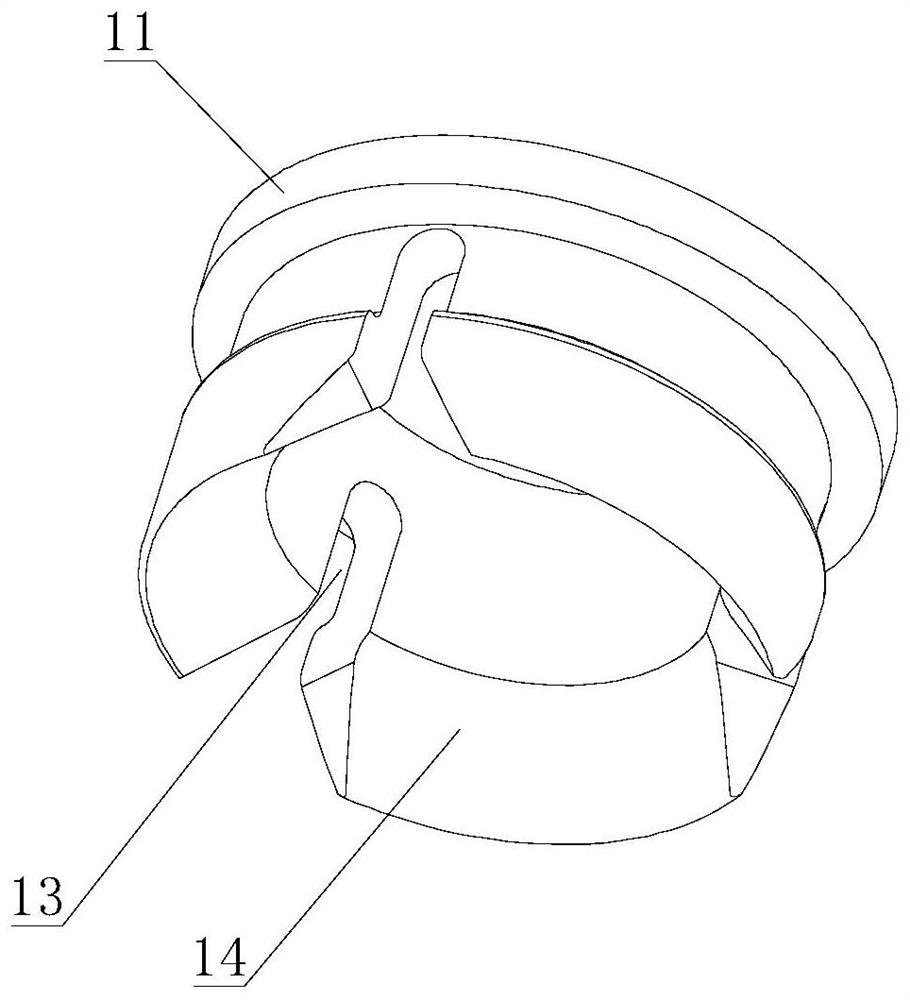

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, an in-line floating connector includes a socket 1 and a plug 2, the socket 1 includes a guide housing 11 and a socket housing 12, and the socket housing 12 is fixedly connected to the guide housing 11 , the socket housing 12 is also provided with an axial floating assembly 3 and a radial floating assembly 4. When the plug 2 and the socket 1 are mated, the plug 2 enters the socket housing 12 through the guide housing 11, and passes through The axial floating component 3 realizes the axial correction floating of the floating connector, and the radial floating component 4 realizes the circumferential and radial correcting floating of the floating connector.

[0027] By setting the axial floating assembly 3 and the radial floating assembly 4 on the socket housing 12, when the plug 2 and the socket 1 are mated, the axial, circumferential and radial correction floating of the floating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com