Anti-icing water tank structure

An anti-icing and water tank technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of low heat utilization rate, inability to heat and antifreeze, etc., achieve high heat utilization rate, novel structure, Effect of avoiding ice damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

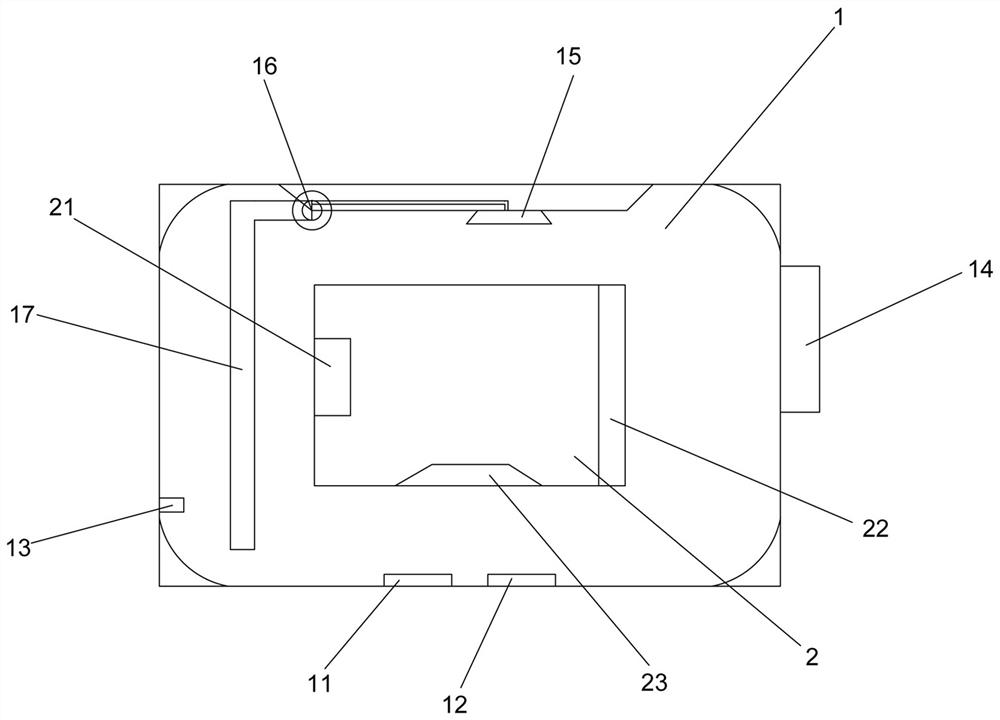

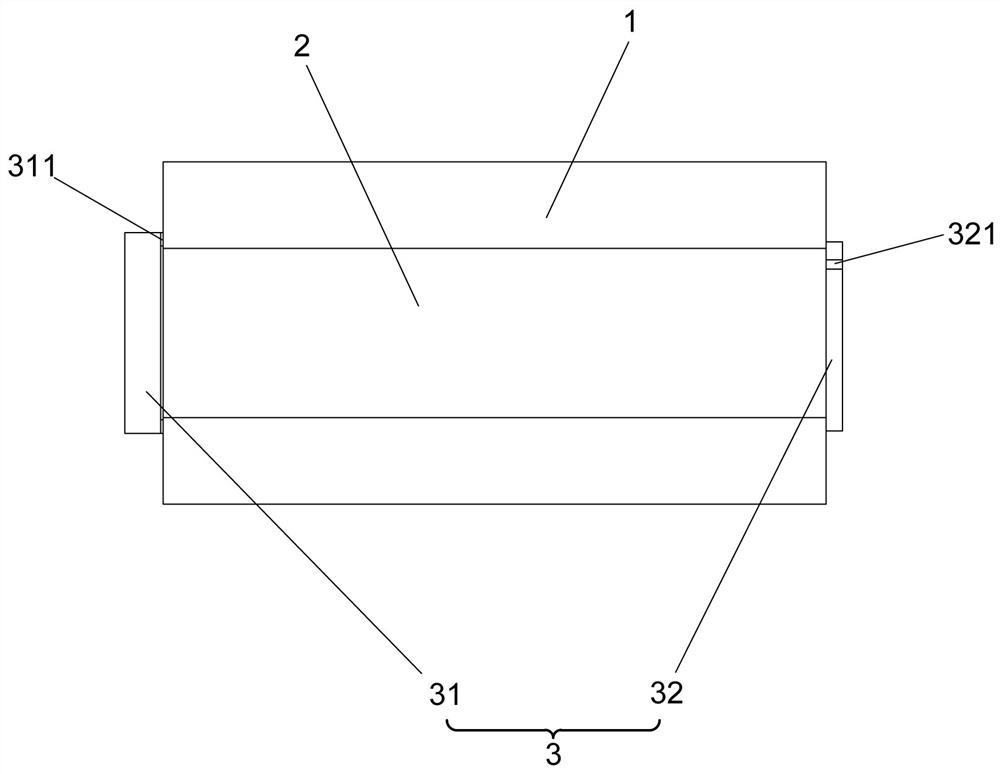

[0029] Embodiment one: if figure 1 , 2 As shown, it is only one of the embodiments of the present invention, an anti-freezing water tank structure, including a back-shaped water tank 1 and an accommodating chamber 2 arranged in the middle of the back-shaped water tank 1, and the inner side of the back-shaped water tank 1 A temperature sensor 11 and a heating device 12 are arranged at the bottom, and a reel 21 for accommodating a water spray pipe, a mounting plate 22 for accommodating a booster pump, and a mounting plate for installing a medicament mixing device are arranged in the accommodating cavity 2 . Mounting seat 23, the inner wall of the back-shaped water tank 1 is provided with a liquid level sensor 13, the outer side of the back-shaped water tank 1 is provided with a display screen 14, the end of the accommodating cavity 2 is provided with a cover 3, the temperature The sensor 11 , the heating device 12 and the liquid level sensor 13 are all electrically connected to...

Embodiment 2

[0038] Embodiment two, still as figure 1 , 2As shown, it is only one of the embodiments of the present invention. On the basis of Embodiment 1, in an anti-freezing water tank structure of the present invention, the top of the back-shaped water tank 1 is provided with a spray head 15, which communicates with the spray head 15 A water pump 16 and a water suction pipe 17 communicating with the water pump 16, the end of the water suction pipe 17 away from the water pump 16 extends toward the bottom of the back-shaped water tank 1 . When the water pump 16 was turned on, the water at the bottom of the zigzag water tank 1 was pumped through the water suction pipe 17, and sprayed from the nozzle 15 nozzles provided on the top of the zigzag water tank 1 to make the water in the zigzag water tank 1 flow, so that the zigzag water tank 1 Water temperature zone balance.

[0039] Here, there are three situations: 1. The water level in the back-shaped water tank 1 is lower than the height ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com