Wear-resistant grinding roller

A grinding roller and welding layer technology, which is applied in the field of wear-resistant grinding rollers, can solve the problems of short service life and poor wear-resistant performance of grinding rollers, and achieve the effects of long service life, improved wear-resistant performance, and reduced possibility of desoldering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

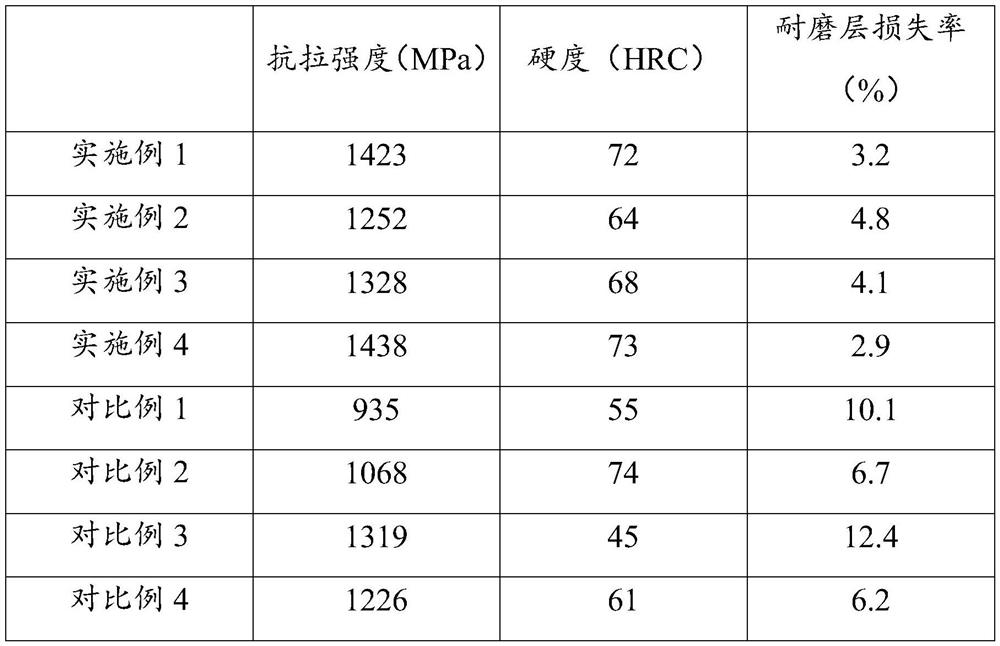

Examples

Embodiment 1

[0027] This embodiment provides a wear-resistant grinding roller, including a base layer, a primer welding layer and a wear-resistant welding layer;

[0028] The weight percentage of the chemical composition of the matrix layer is: C: 0.25%, Si: 1.1%, Mn: 0.9%, Re: 0.025%, S: 0.012%, P: 0.009%, Cr: 0.9%, and the balance is Fe;

[0029] The weight percentage of the chemical composition of the bottom soldering layer is: C:0.42%, Si:1.2%, Cr:22%, Ni:10%, S:0.005%, P:0.003%, Mn:0.6%, Ti:0.12% , the balance is Fe; the welding thickness is 20mm;

[0030] The chemical composition weight percent of the wear-resistant welding layer is: C: 0.45%, Si: 1.2%, Cr: 18%, Ni: 10%, S: 0.006%, P: 0.002%, Mn: 0.3%, Nb: 0.5% , Ti: 0.5%, W: 2.3%, the balance is Fe; the welding thickness is 6mm.

Embodiment 2

[0032] This embodiment provides a wear-resistant grinding roller, including a base layer, a primer welding layer and a wear-resistant welding layer;

[0033] The weight percent of the chemical composition of the matrix layer is: C: 0.22%, Si: 1.2%, Mn: 1.1%, Re: 0.03%, S: 0.013%, P: 0.01%, Cr: 0.8%, and the balance is Fe;

[0034] The weight percentage of the chemical composition of the bottom soldering layer is: C:0.4%, Si:1%, Cr:25%, Ni:8%, S:0.005%, P:0.005%, Mn:0.09%, Ti:0.05% , the balance is Fe; the welding thickness is 15mm;

[0035] The weight percentage of the chemical composition of the wear-resistant welding layer is: C: 0.4%, Si: 1%, Cr: 25%, Ni: 8%, S: 0.003%, P: 0.005%, Mn: 0.09%, Nb: 0.4% , Ti: 0.3%, W: 2%, the balance is Fe; the welding thickness is 8mm.

Embodiment 3

[0037] This embodiment provides a wear-resistant grinding roller, including a base layer, a primer welding layer and a wear-resistant welding layer;

[0038] The weight percent of the chemical composition of the matrix layer is: C: 0.28%, Si: 0.9%, Mn: 0.8%, Re: 0.01%, S: 0.018%, P: 0.012%, Cr: 1.1%, and the balance is Fe;

[0039]The weight percentage of the chemical composition of the bottom welding layer is: C: 0.5%, Si: 1.5%, Cr: 15%, Ni: 12%, S: 0.006%, P: 0.002%, Mn: 1.1%, Ti: 0.2% , the balance is Fe; the welding thickness is 25mm;

[0040] The chemical composition weight percent of the wear-resistant welding layer is: C: 0.5%, Si: 1.5%, Cr: 15%, Ni: 12%, S: 0.008%, P: 0.005%, Mn: 1.1%, Nb: 0.8% , Ti: 0.6%, W: 3%, the balance is Fe; the welding thickness is 5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com