Die steel hoisting and clamping device

A die steel and hoisting technology, applied in the direction of hoisting device, lifting frame, etc., can solve the problems of fixed transportation position, unsuitable for large-scale promotion and use, and inability to use flexibly, so as to improve hoisting efficiency, work efficiency and general use. Sexual, well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

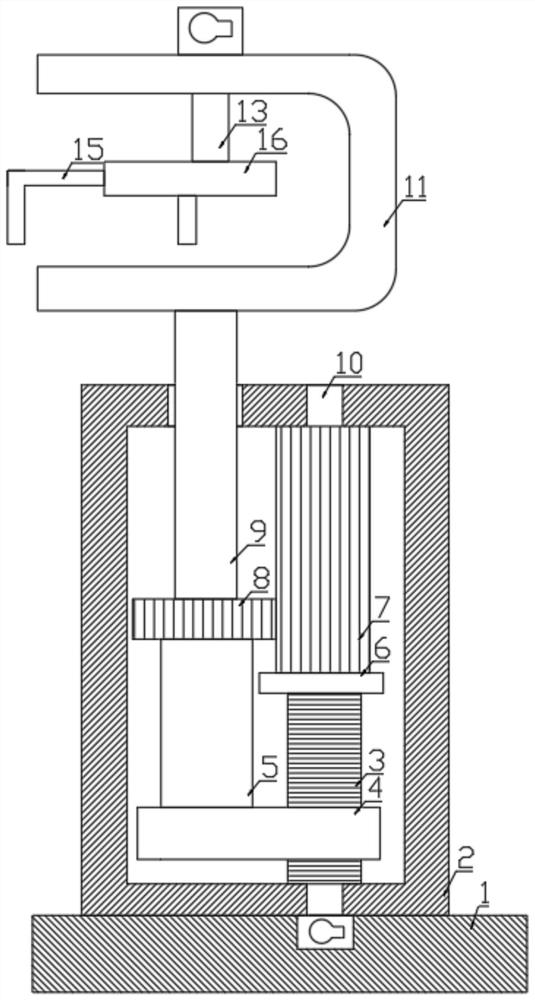

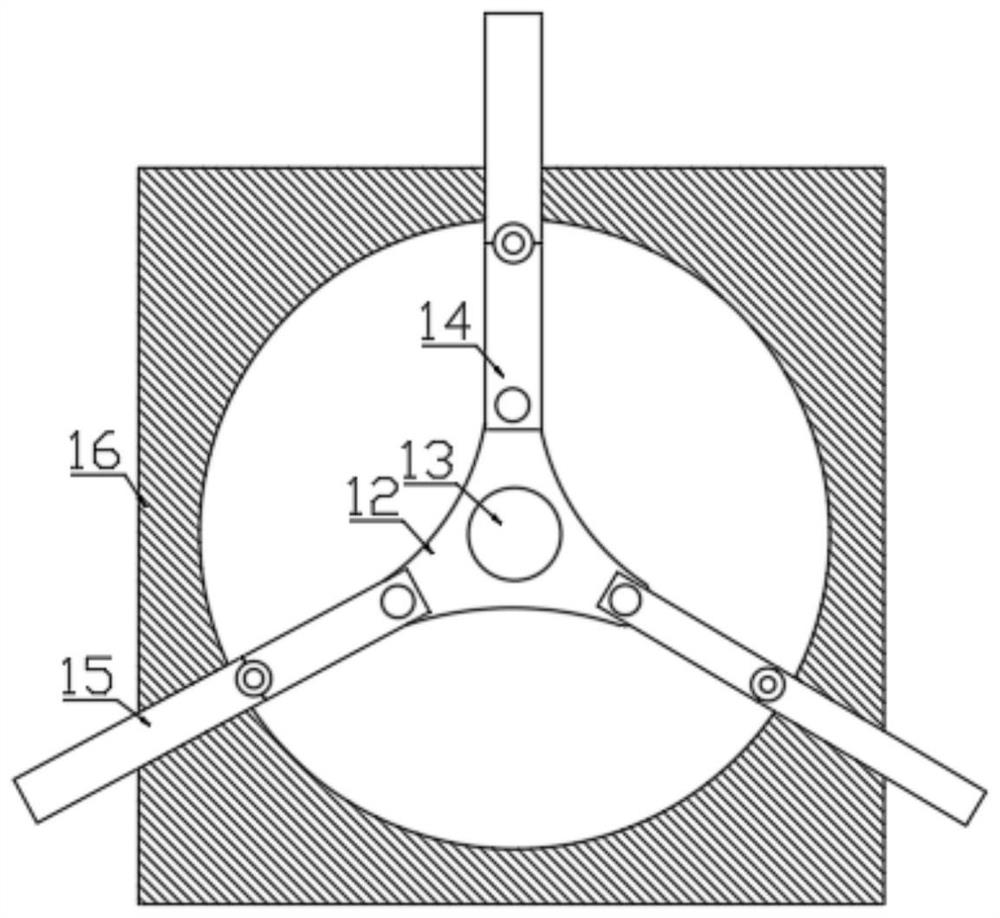

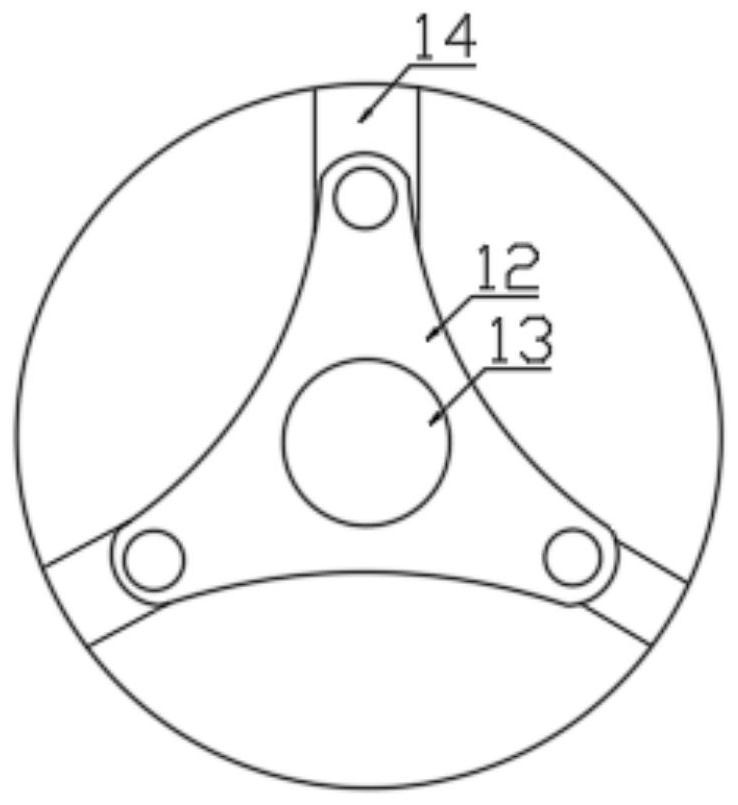

[0021] Example 1: Please refer to Figure 1~4 , in an embodiment of the present invention, a mold steel hoisting and clamping device includes a base 1, a device box 2 is fixedly arranged on the upper side of the base 1 and a driving shaft 10 is arranged on the right side of the inside of the device box 2, and the outer side of the lower end of the driving shaft 10 is fixedly installed There is a leading screw 3 and the outer side of the leading screw 3 is equipped with a sliding sleeve 4, the outer side of the upper end of the driving shaft 10 is fixedly provided with a driving wheel 7 and the left side of the driving wheel 7 is equipped with a driven wheel 8, and the upper end of the sliding sleeve 4 is fixedly connected to the push rod 5 and The upper end of the pushing rod 5 is slidingly connected to the driven wheel 8, the upper end of the driven wheel 8 is fixedly connected to the moving rod 9 and the upper end of the moving rod 9 is fixedly connected to the clamping frame...

Embodiment 2

[0022] Embodiment 2: The invention also provides another embodiment, which is improved on the basis of the above embodiment. The inside of the clamping rod 15 is provided with an anti-slip layer to prevent the die steel from being clamped during the clamping process. slide.

[0023] The working principle of the present invention: start the motor to rotate the driving shaft 10 connected to it, the driving shaft 10 drives the screw 3 and the driving wheel 7 fixedly installed with it to rotate, and the rotation of the leading screw 3 drives the sliding sleeve 4 installed with it to carry out Moving vertically up and down, the sliding sleeve 4 drives the pushing rod 5 fixedly connected with it to move vertically up and down, and the pushing rod 5 drives the driven wheel 8 which is slidingly connected with it to move up and down, and then the clamping frame 11 is moved up and down through the moving rod 9 For height adjustment, the driving wheel 7 rotates to drive the driven wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com