Precast concrete pipe pile

A technology of concrete pipe piles and prefabricated concrete, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, etc. It can solve the problems of potential safety hazards and insufficient stability of the joints of concrete pipe piles, so as to avoid stability performance and improve stability , Strengthen the effect of stabilizing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

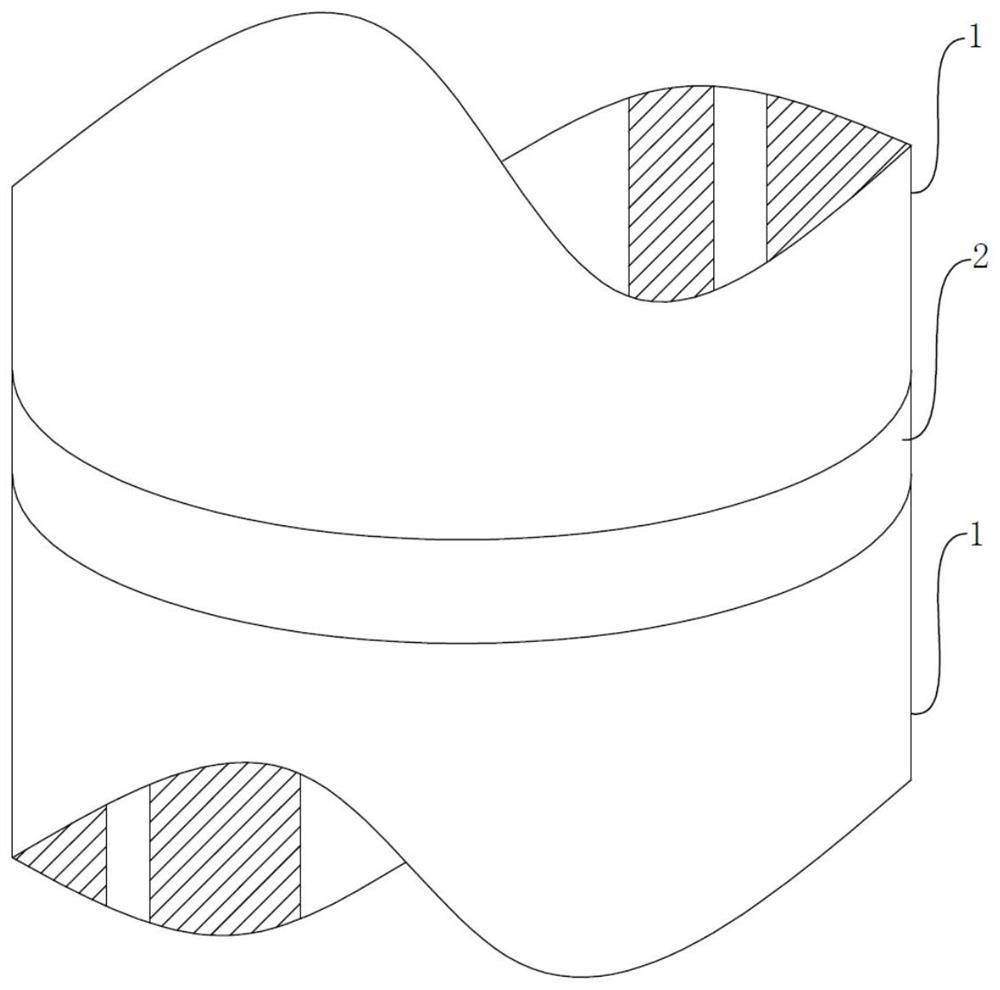

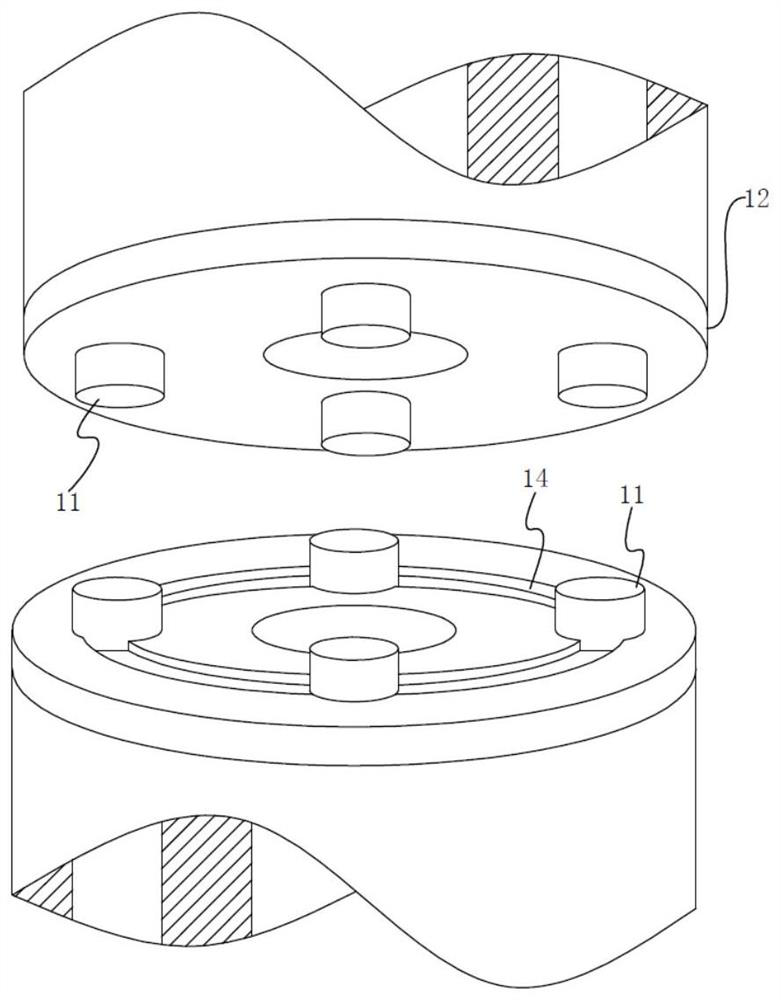

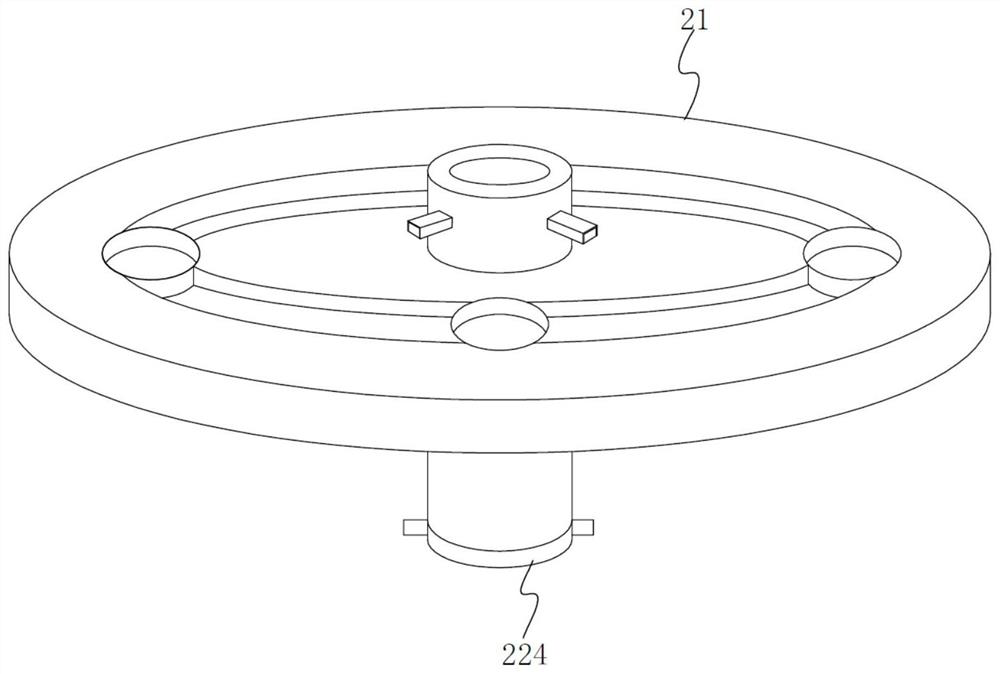

[0029] See Figures 1 to 10 The present invention provides a technical solution:

[0030] A prefabricated concrete pipe pile comprising an air-shaped condensate pipe pile section 1, which is sequentially distributed in sequence, and a pile section 2 of the adjacent two concrete pipe pile sections 1, the pre-concrete The pipe pile includes a number of steel bars 11 which are disposed in the inner wall of the concrete pipe pile section 1, and the end plate 12 disposed at the end of the concrete pipe pile section, wherein the pile segment connecting device 2 includes two adjacent two. The outer diameter of the outer diameter of the concrete pipe pile section 1 is the same, the upper upper end, and the lower ends of the ring plate 21 are fixed, and the junction device 22, which is uniformly opened on the connecting ring plate 21. Several through holes I211, the inner portion of the through hole I211 is provided with a separator 212, and the material of the separator 212 is used for bon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com