Lithium battery module multichannel balanced charging and discharging maintenance testing device

A technology for equalizing charge and discharge, maintenance testing, applied in secondary battery charging/discharging, secondary battery testing, measuring devices, etc. Balanced application, inappropriate clip size, etc., to avoid unreliable probe contact, improve the balance of charge and discharge current, and prevent short circuit hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

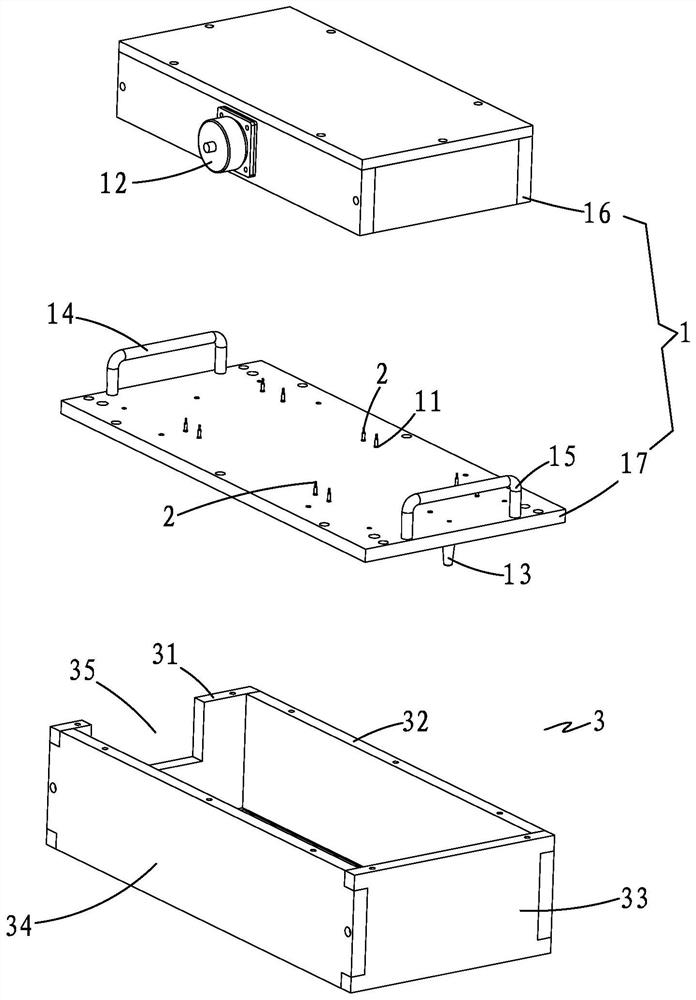

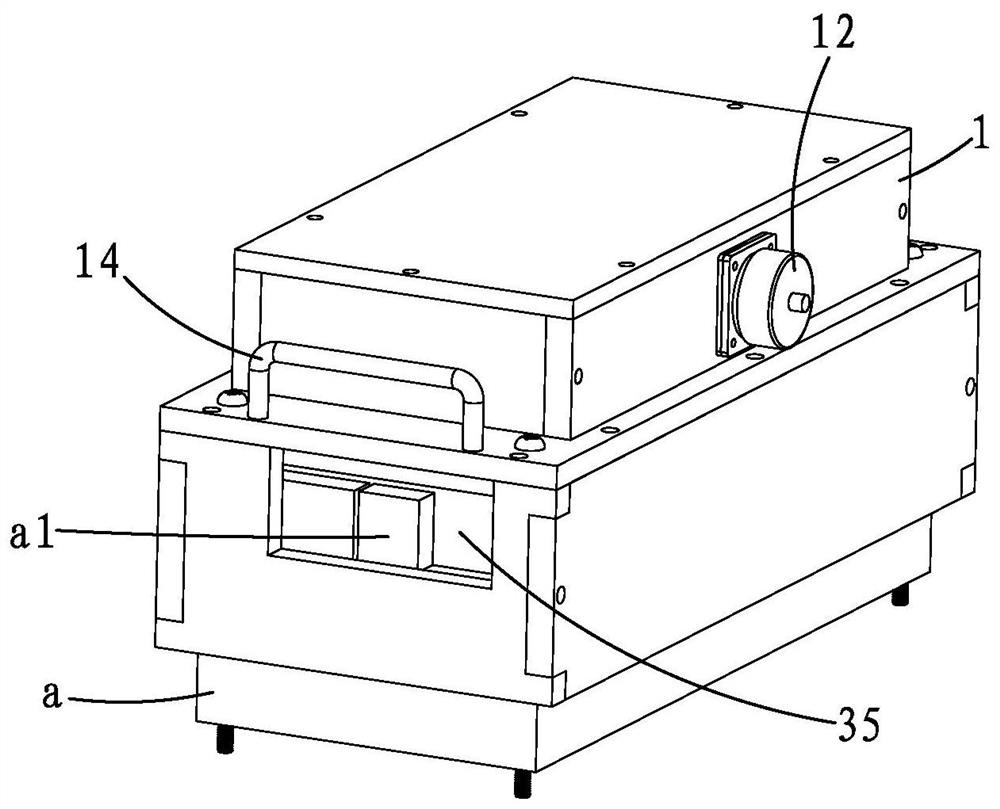

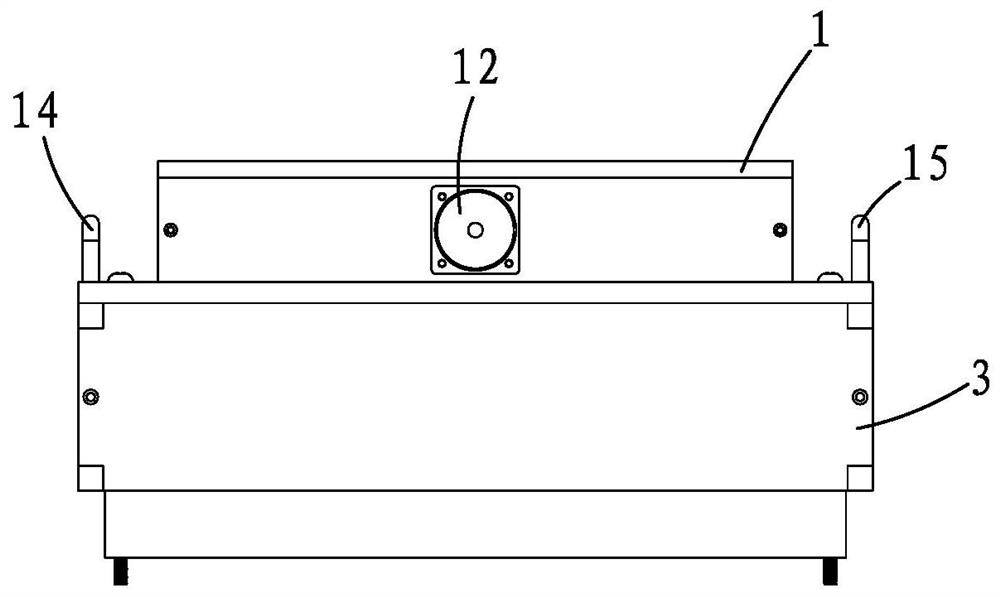

[0027] see Figure 1 to Figure 5 As shown, the present invention is realized as follows: a lithium battery module multi-channel balanced charge and discharge maintenance test device, including a battery fixing structure upper cover 1, the battery fixing structure upper cover 1 is provided with a plurality of fixed hole 11 and a socket 12, the upper cover 1 of the battery fixing structure is provided with a protruding portion 13, and an upwardly protruding socket port a1 is provided on the battery module a. If the battery module a is installed upside down, the The protruding part 13 will top the socket a1, making it impossible to insert the battery module a, and let the user know that it is installed upside down; if it is not reversed, the corresponding part of the battery module a is a groove, and the protruding part 13 can be inserted into the groove; The battery fixing structural member upper cover 1 is a transparent structure, the socket 12 is an aviation socket, and the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com