Mini-type cultivator

A micro tillage and complete machine technology, applied in the field of farmland tillage machinery, can solve the problems of low power and operating costs, and achieve the effects of saving operating costs, convenient replacement and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

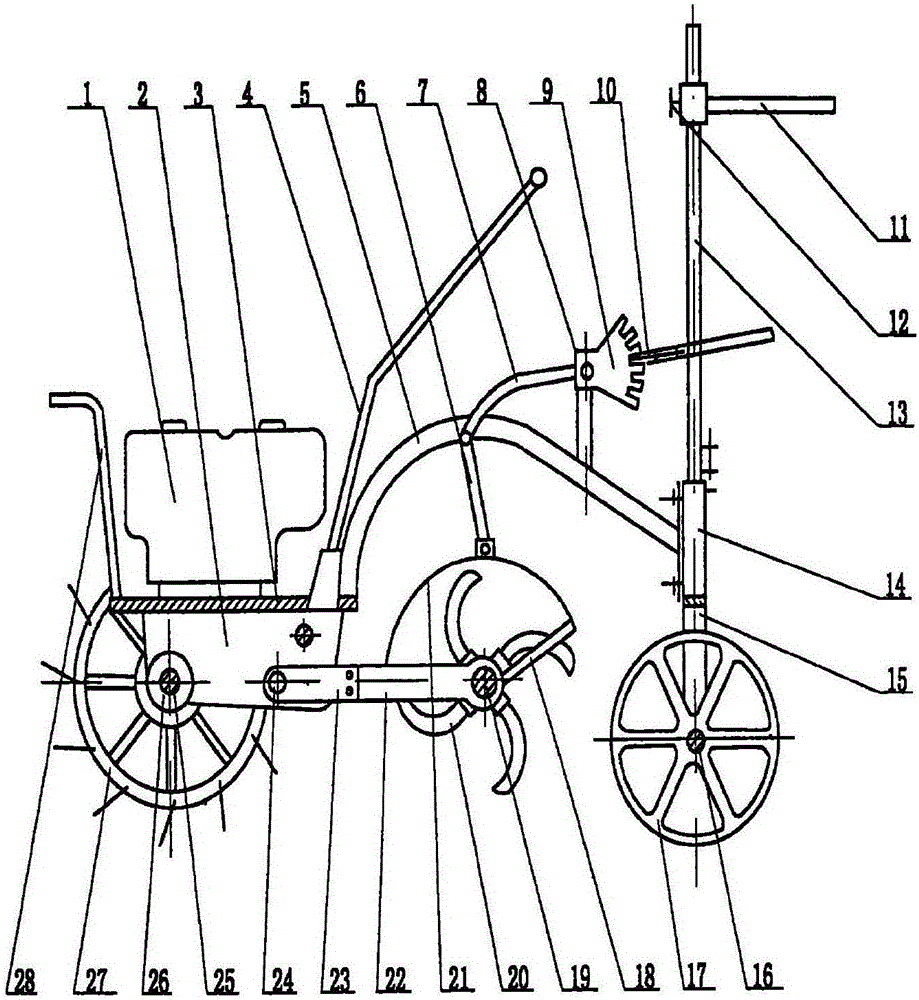

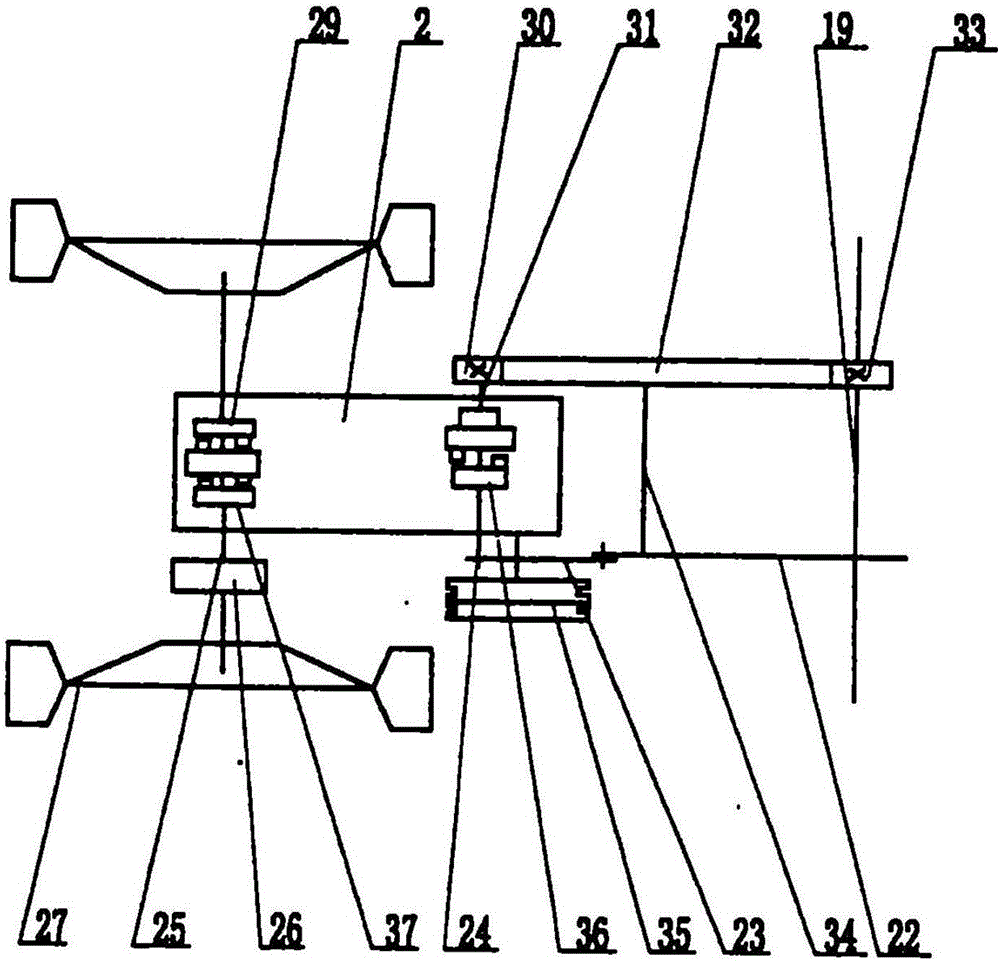

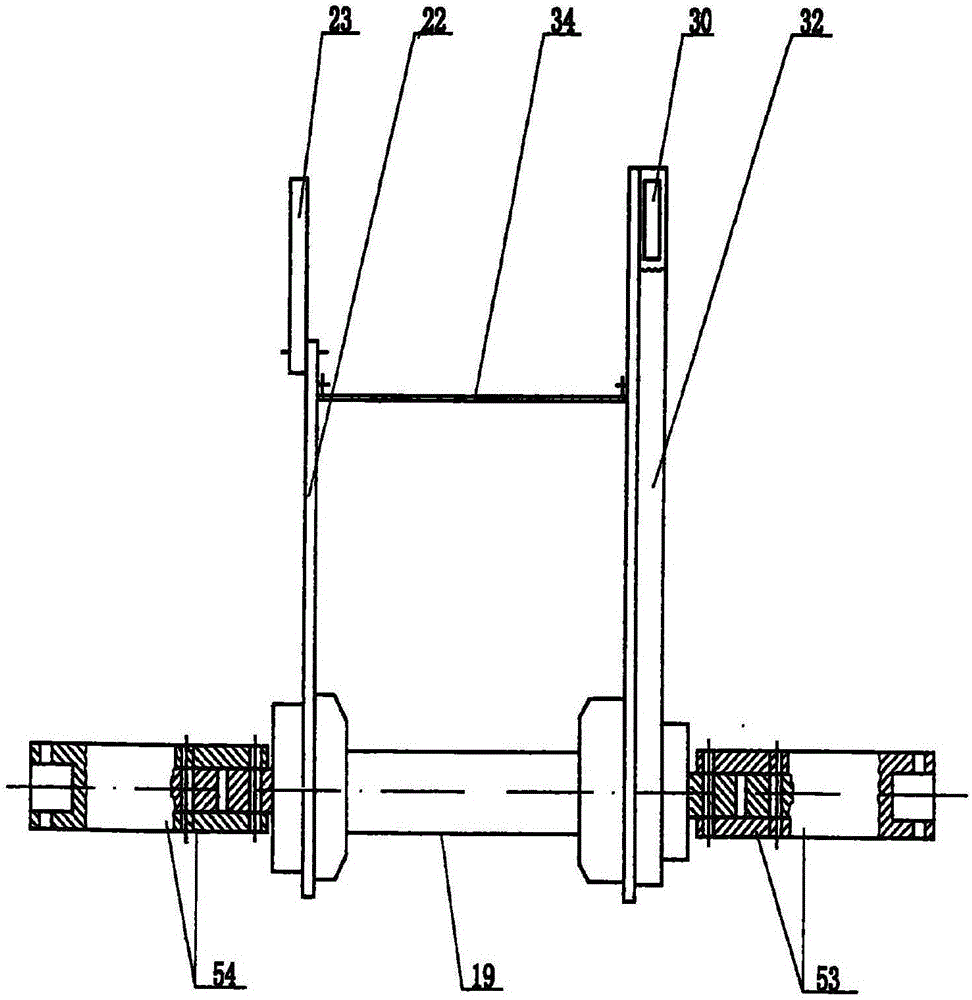

[0025] Such as figure 1 As shown, an engine is arranged on the frame plate 3, and a gearbox 2 is arranged below it. A walking wheel 27 is arranged on both sides of the front of the gearbox, which is connected to both ends of its shaft through a wheel shaft 25. The wheels can be exchanged according to the needs of the operation. The wheel axle 16 is provided with a brake wheel 26, and an armrest frame 11 is set on the upper part of the wheel rod 13 above the rear end of the frame 5. Its height can be adjusted by bolts 12 and through its bolts. Immediately connected to the wheel rod, the lower end of the wheel rod 13 passes through the shaft sleeve 14 and is connected to the wheel fork 15, and the wheel fork is connected to the steering wheel 17 through the wheel shaft 16. The components of the tillage device are arranged under the frame 5, the cutter shaft 19 is designed as a combined type, and the length of the shaft can be increased or decreased to connect the shaft section 53 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com