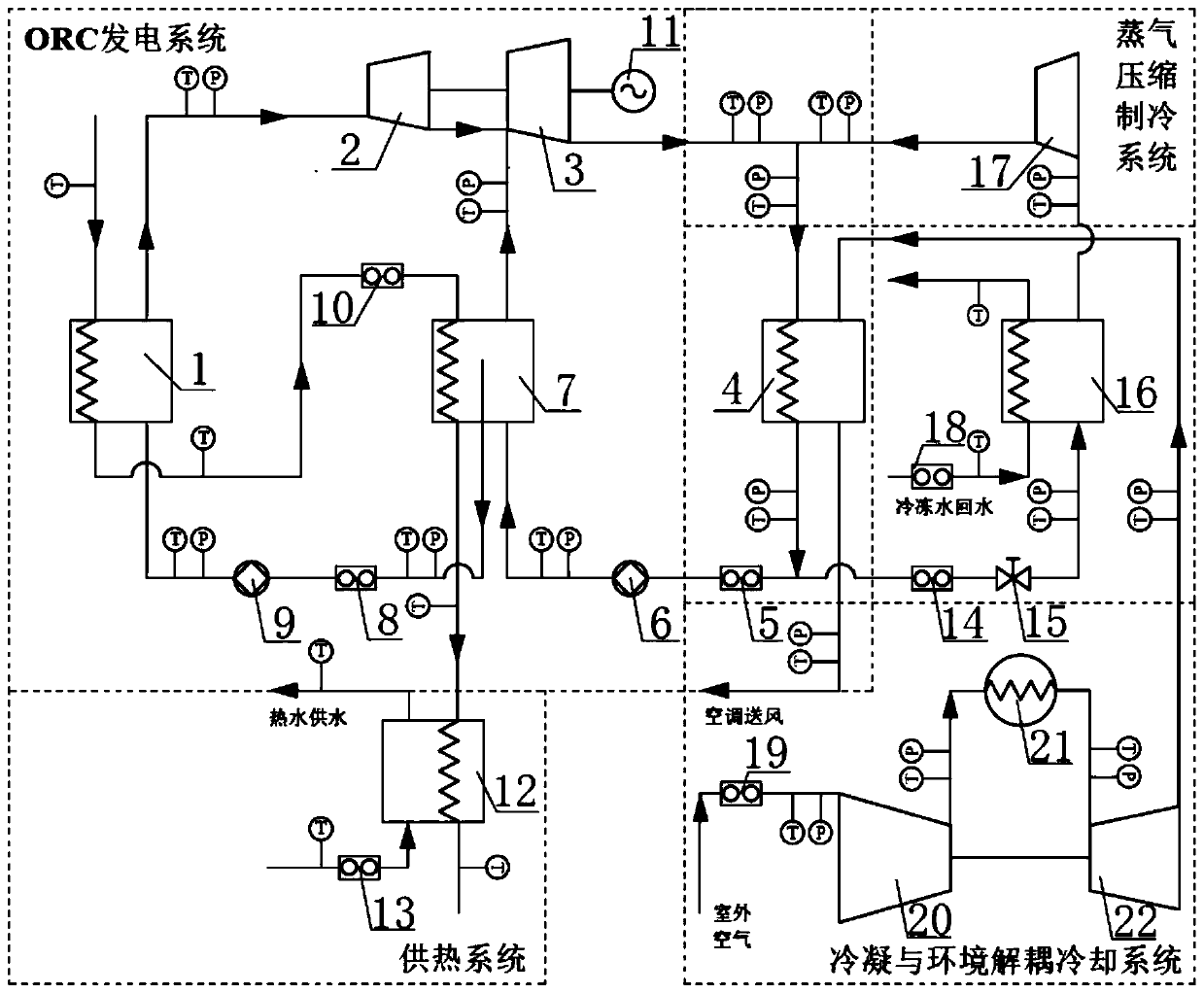

Cold, heat and electricity cogeneration system coupling condensation decoupling and cascade evaporation

A combined cooling, heating and power generation, cascade technology, applied in the direction of heating and cooling combination, refrigerator, refrigeration components, etc., can solve the problems of environmental pollution, inability to make full use of everything, high heat exhaust temperature of the system, and achieve compact structure and easy Conditioning and control, improving poor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] After the outdoor air passes through the air compressor 20, the air cooler 21 and the third expander 22, the temperature decreases (in this embodiment, the temperature is lowered to 5° C.), which can be significantly lower than the ambient temperature (the ambient temperature in this embodiment is 20° C.), Thus, the decoupling between the condensation process of the ORC power generation system and the vapor compression refrigeration system and the ambient state is realized; the cooled air is used as the cold source of the ORC power generation system and the vapor compression refrigeration system, which can reduce the working fluid in the condenser 4. The condensing temperature improves the power generation performance of the ORC power generation system; it also reduces the pressure ratio and power consumption of the vapor compression refrigeration system, thereby improving the performance coefficient of the vapor compression refrigeration system; in summer, the outdoor dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com