Vehicle electrical equipment end waterproof interface

A technology for electrical equipment and electrical equipment, applied in the field of waterproof interface at the end of vehicle electrical equipment, can solve the problems of reducing the assembly efficiency of the whole vehicle, falling off, easy loosening of seals, etc. and shedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

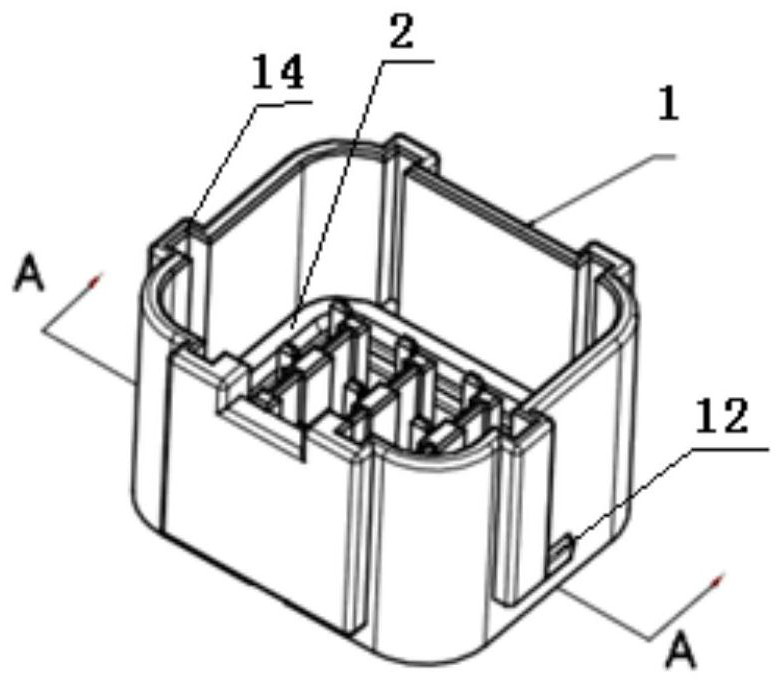

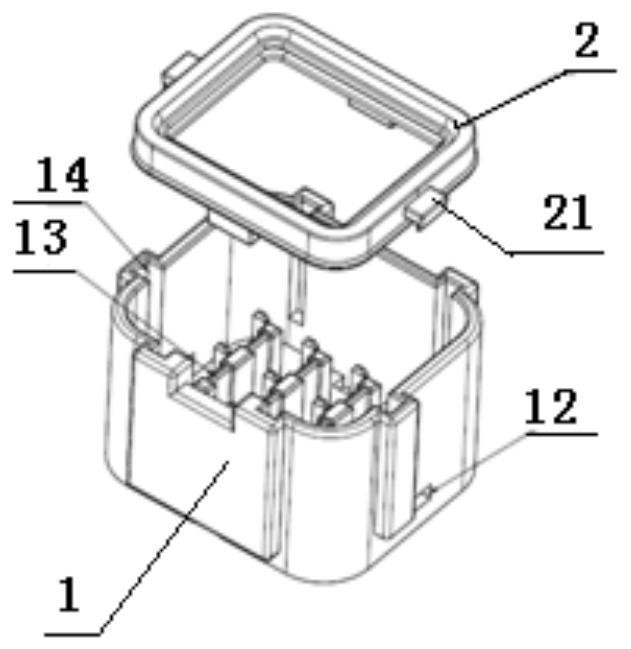

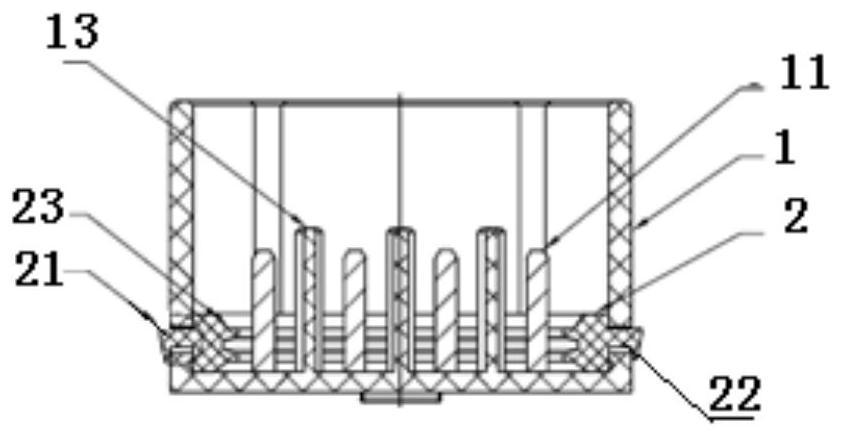

[0021] The present invention is further described below in conjunction with accompanying drawing:

[0022] Such as Figure 1-6 Shown is a waterproof interface of a vehicle electrical equipment end, comprising a plastic sheath 1, a conductive pin 11 injection-molded with the plastic sheath 1 and a seal 2 for sealing, and the conductive pin 11 is fixed on the plastic sheath. The bottom of the sleeve 1 is arranged vertically, the sealing member 2 is ring-shaped and located on the periphery of the conductive pin 11 in the bottom of the plastic sheath 1, and a protruding hooking structure 21 is provided on the outside of the sealing member 2. The plastic sheath 1 is provided with a hanging interface 12, and the hooking structure 21 cooperates with the hanging interface 12.

[0023] The seal 2 is provided with a hook structure 21, and the plastic sheath 1 is provided with a hook interface 12. The plastic sheath 1 and the seal 2 are fixed through the hook structure 21 and the hang i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap