Endoscope snake bone unit, snake bone assembly and endoscope

A technology of endoscope and snake bone, which is applied in the fields of endoscope, medical science, diagnosis, etc., can solve the problems of increasing the difficulty of manufacturing, weak connection strength, low production efficiency, etc., and achieve the reduction of connection parts and high connection strength , the effect of not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] In this example, the front and rear orientations, when the endoscope is in use, the side facing the patient is the front, and the side facing away from the patient is the rear.

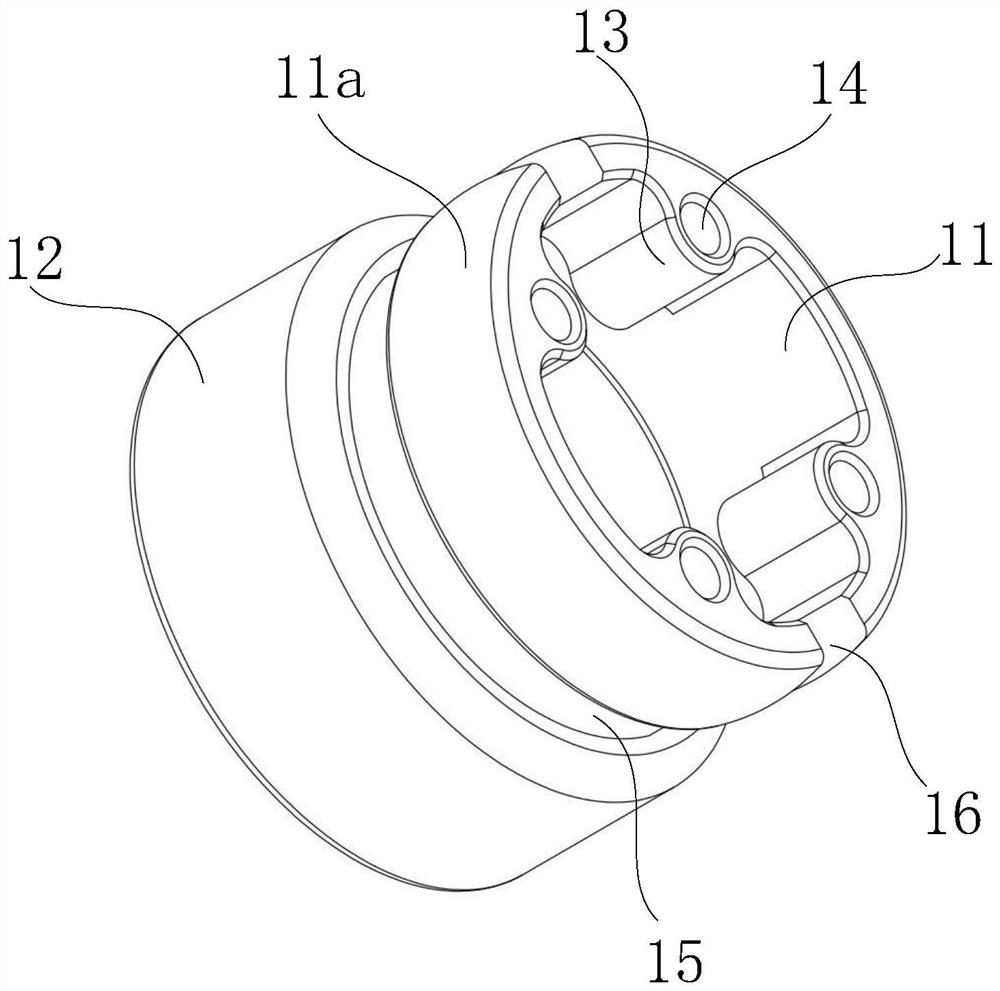

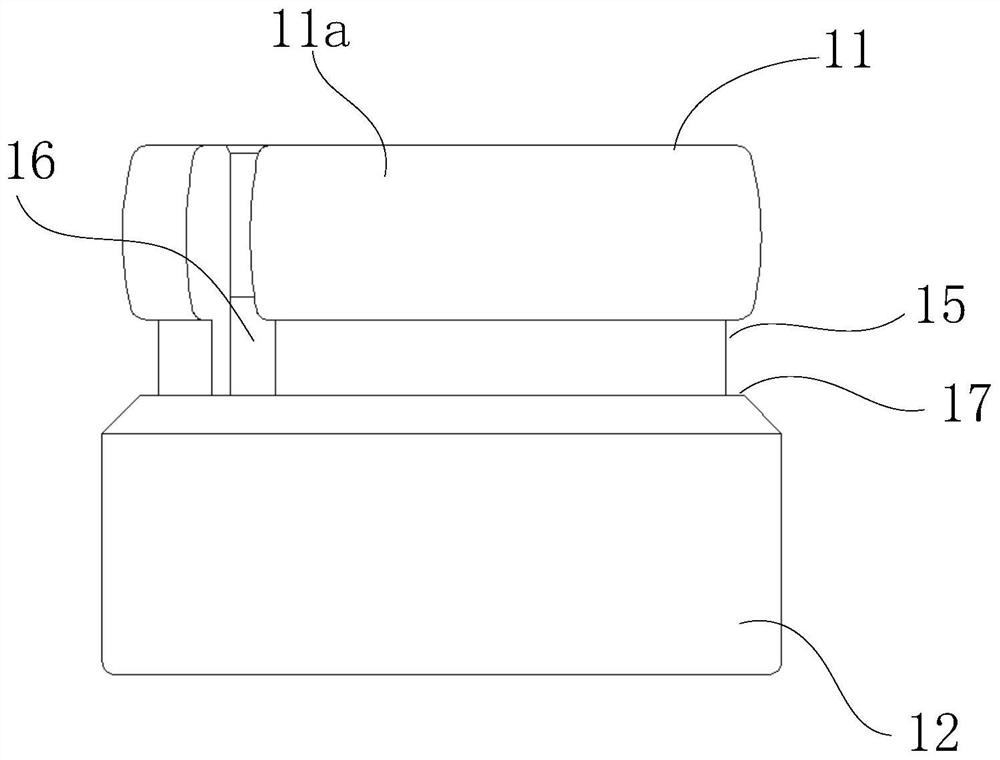

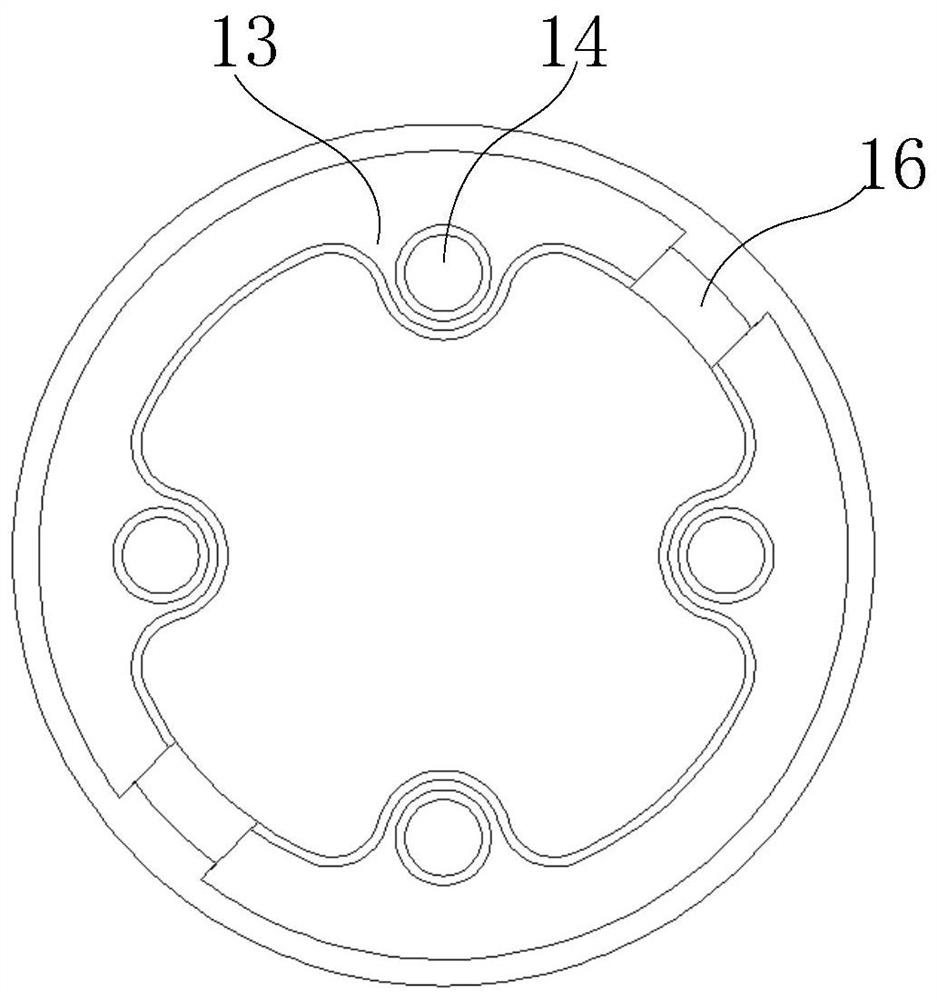

[0032] Such as Figure 1 to Figure 5 As shown, a kind of endoscopic snake bone unit illustrated in this example is used to connect in series to form the bending part of the endoscope; The ends (i.e., the front and rear ends) are respectively the first connection end 11 and the second connection end 12 (or become the first joint and the second joint), wherein the outer wall of the first connection end 11 is provided with a ring of protrusions along the circumferential direction. part 11a, wherein the protruding part 11a is continuous or discontinuous in the circumferential direction; the inner wall of the second connecting end 12 is provided with a circle of concave parts 12a along the circumferential direction, and the size of the concave part 12a is matched with the protruding part 11a, so as ...

Embodiment 1

[0044] The difference of Embodiment 1 is that the protruding part 12c is arranged on the outer wall of the first connecting end 11, and the concave part 11c is arranged on the inner wall of the second connecting end 12, such as Figure 6 As shown, that is, the outer wall of the first connecting end 11 is provided with a concave portion 11c along the circumference, and the inner wall of the second connecting end 12 is provided with a corresponding convex portion 12c as described in the concave portion 11c, and the minimum diameter of the convex portion 12c is Greater than or equal to the minimum outer diameter of the recessed part 11c (that is, the arc radius of the protruding part 12c is greater than or equal to the arc radius of the recessed part 11c), and smaller than the maximum outer diameter of the recessed part 11c, so as to achieve anti-off; the second connecting end 12 is away from One end (rear end) of the first connecting end 11 forms a flaring, and the maximum diamet...

Embodiment 3

[0046] The present invention also provides a snake bone assembly, including at least two endoscopic snake bone units 100 described in Embodiment 1 or Embodiment 2; each snake bone unit 100 is connected in series to form the snake bone assembly, and two adjacent snake bones In the unit 100, the second connecting end 12 of the previous snake-bone unit 100 is sleeved outside the first connecting end 11 of the latter snake-bone unit 100, so that two adjacent snake-bone units 100 can be axially and circumferentially Relatively rotate, and through the cooperation of the concave part and the convex part, two adjacent snake bone units 100 are restricted from disengaging. Assembly relationship such as Figure 7 and Figure 8 shown, where Figure 7 The direction of the middle arrow is the socket direction, Figure 8 What is shown is a schematic diagram of nesting adjacent snake bone units 100 together. The anti-separation between adjacent snake bone units 100 is realized by relying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com