Rubber belt track secondary utilization device without regeneration

A rubber track and workbench technology, applied in the field of recycling, can solve the problems of harsh use environment, rubber track damage, unsafety, etc., and achieve the effect of improving utilization rate and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

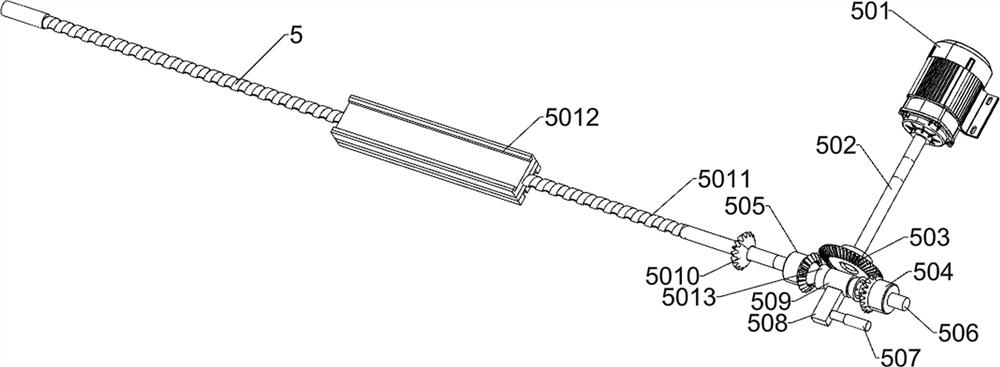

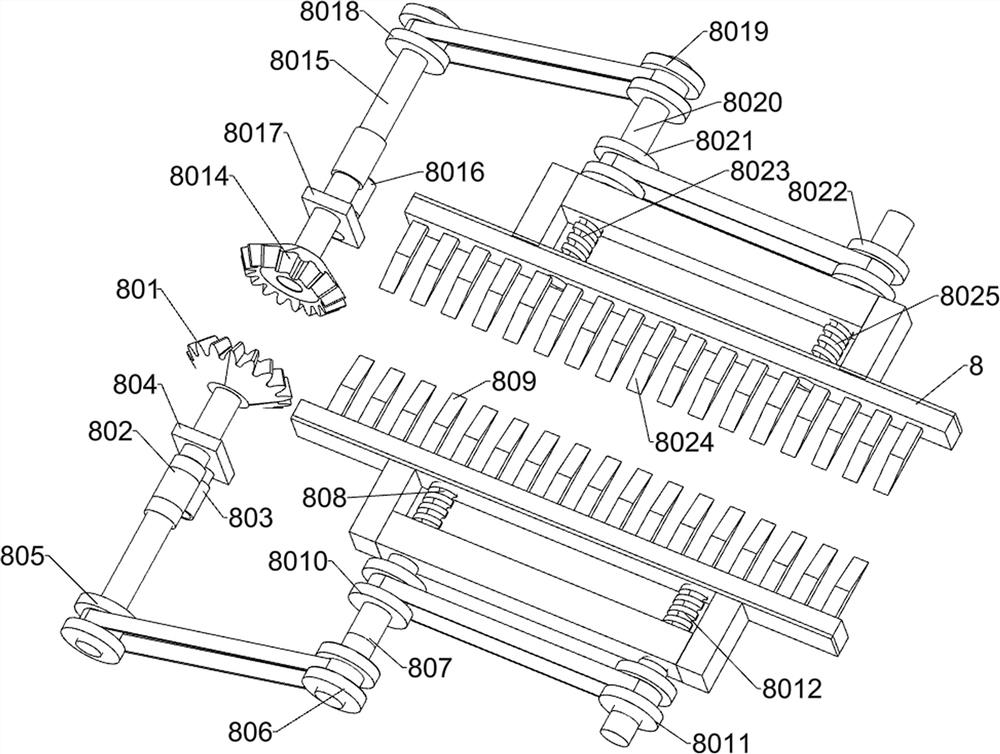

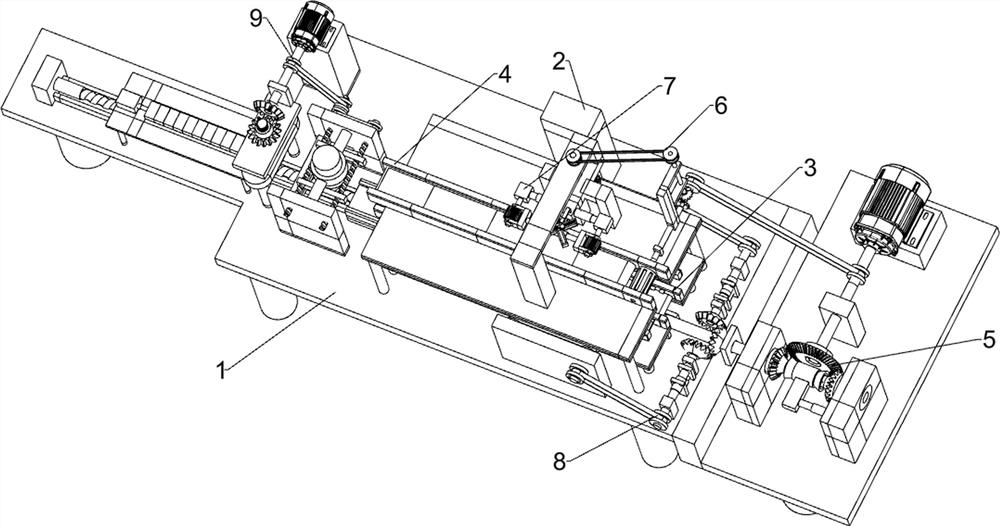

[0028] A rubber crawler secondary utilization device without regeneration, such as Figure 1-7 As shown, it includes a workbench 1, a control panel 2, a first conveying assembly 3, a second conveying assembly 4, a transport assembly 5, a cutting assembly 6, a scraping assembly 7, a separating assembly 8 and a smearing assembly 9; the workbench 1 and The control panel 2 is connected; the workbench 1 is connected with the first conveying assembly 3; the workbench 1 is connected with the second conveying assembly 4; the workbench 1 is connected with the transport assembly 5; the workbench 1 is connected with the cutting assembly 6; The workbench 1 is connected with the scraping assembly 7; the workbench 1 is connected with the separation assembly 8; the workbench 1 is connected with the smear assembly 9; the first transmission assembly 3 is connected with the separation assembly 8; the second transmission assembly 4 is connected with the cutting assembly The components 6 are conn...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap