Patents

Literature

32results about How to "Realize the function of removing impurities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

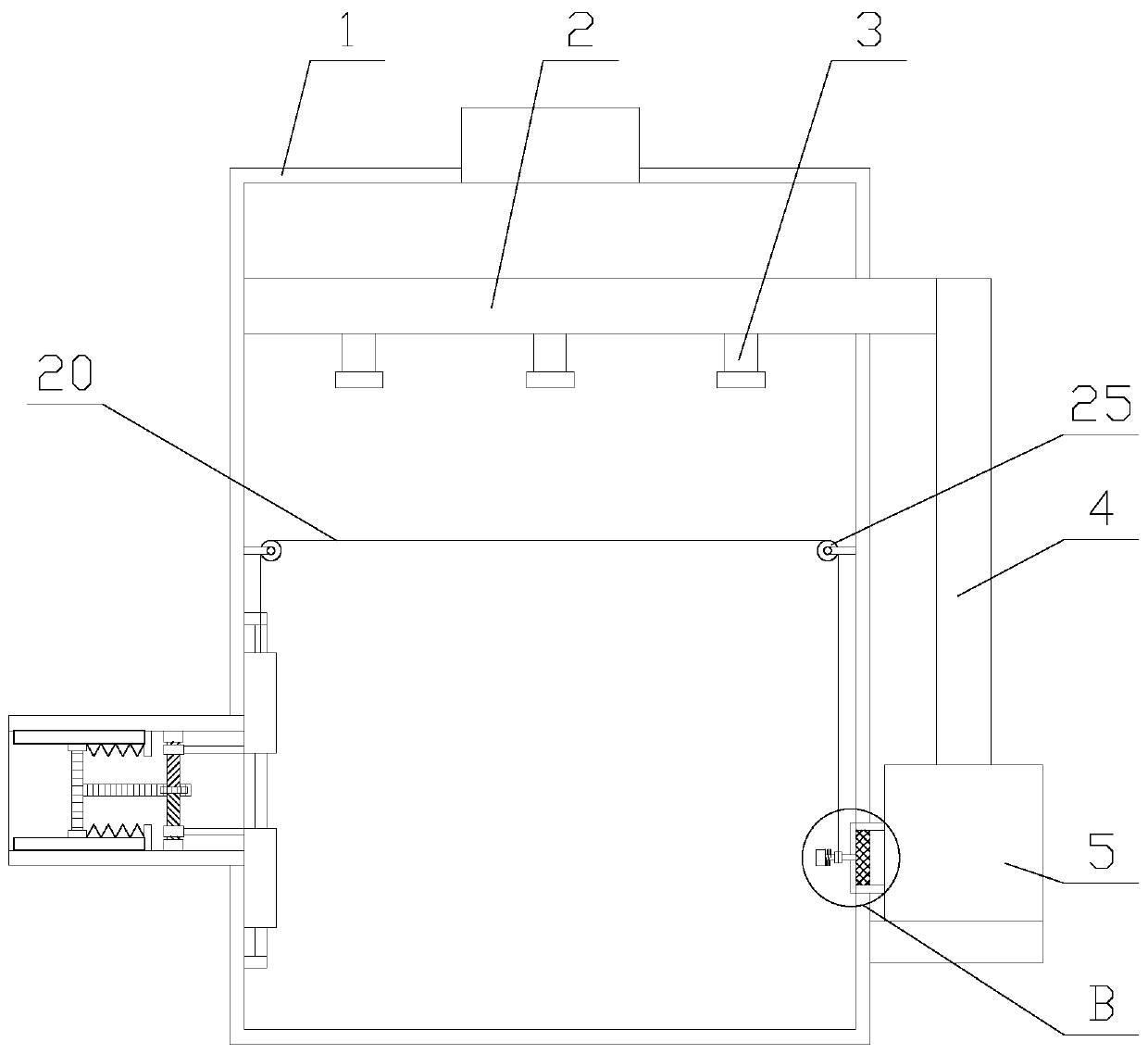

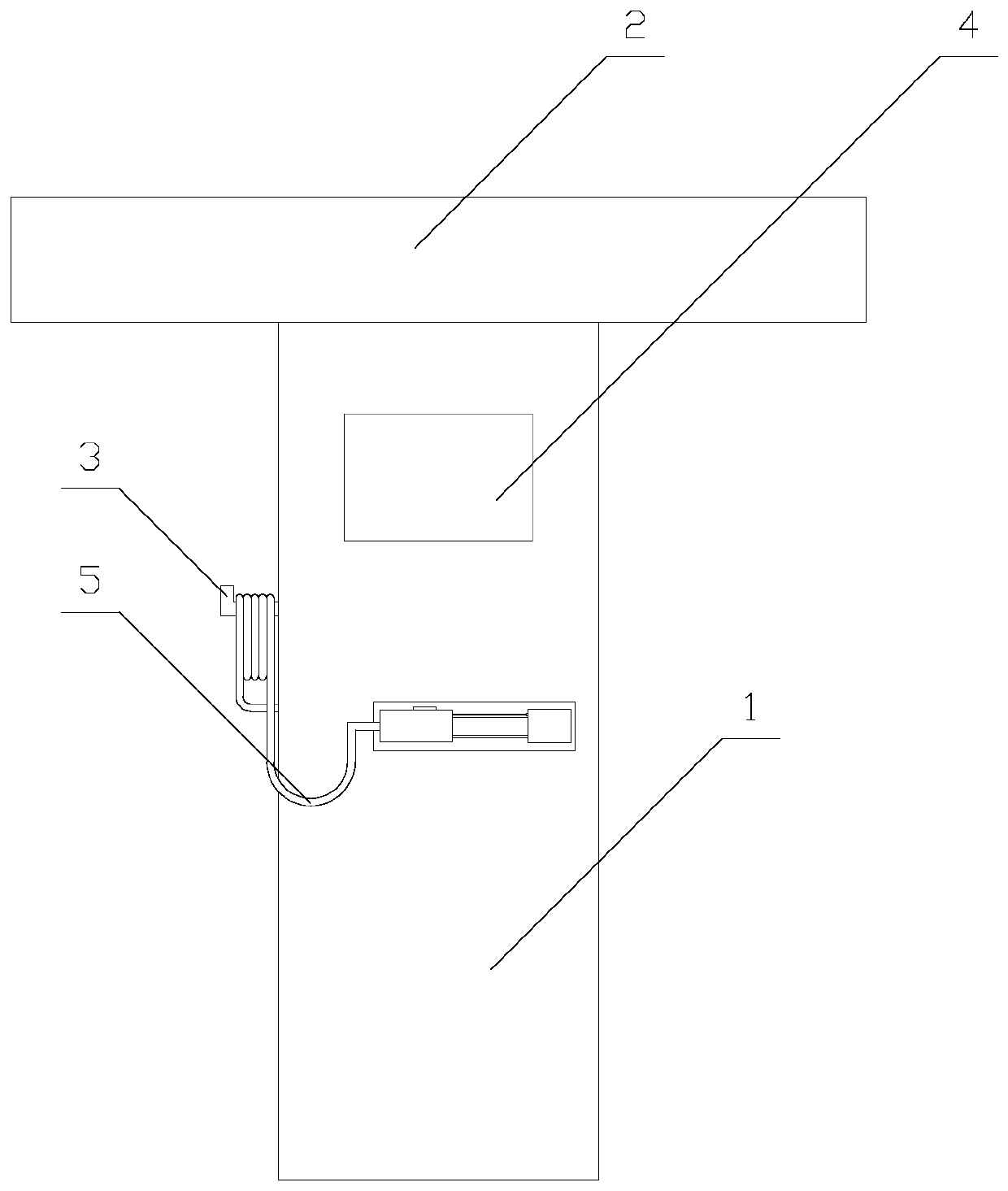

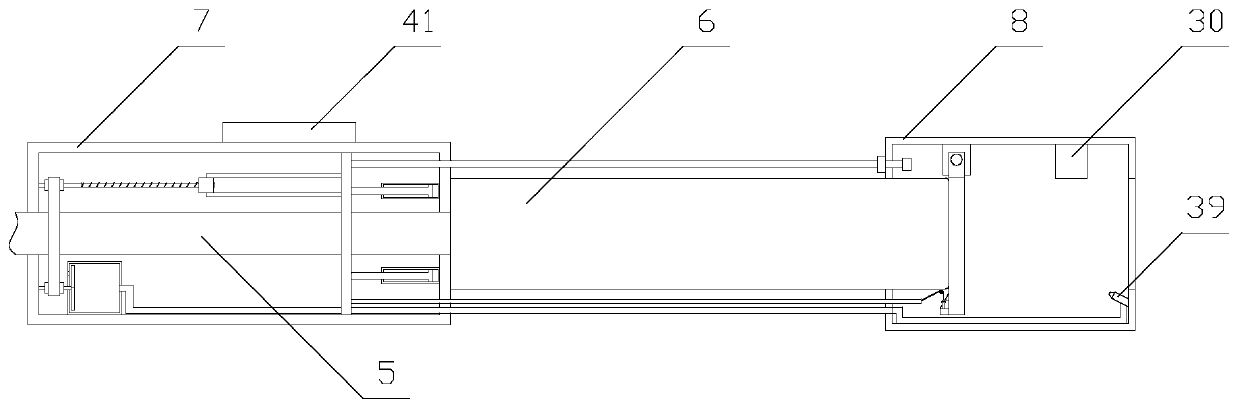

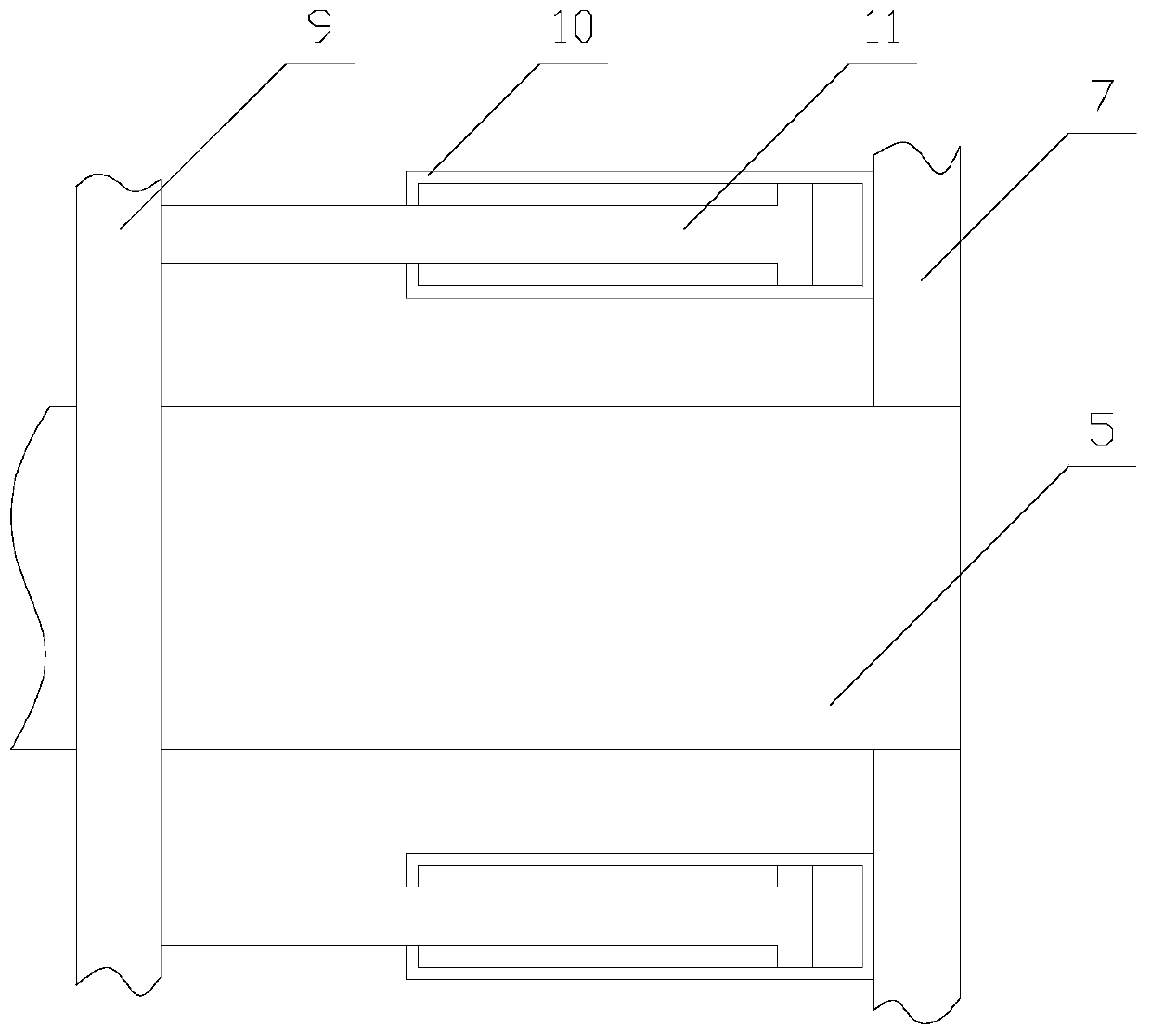

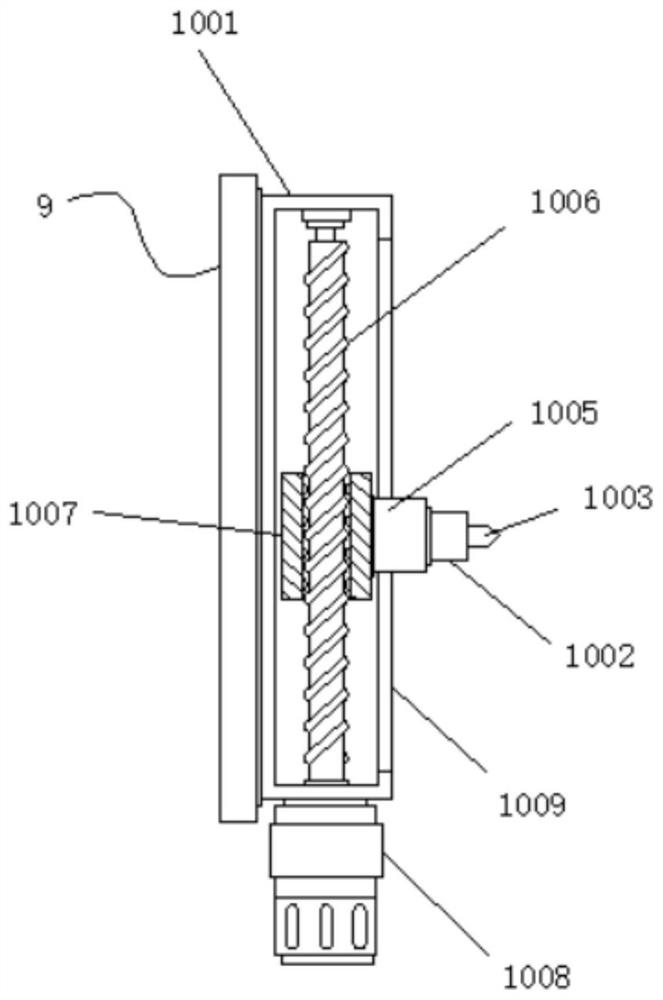

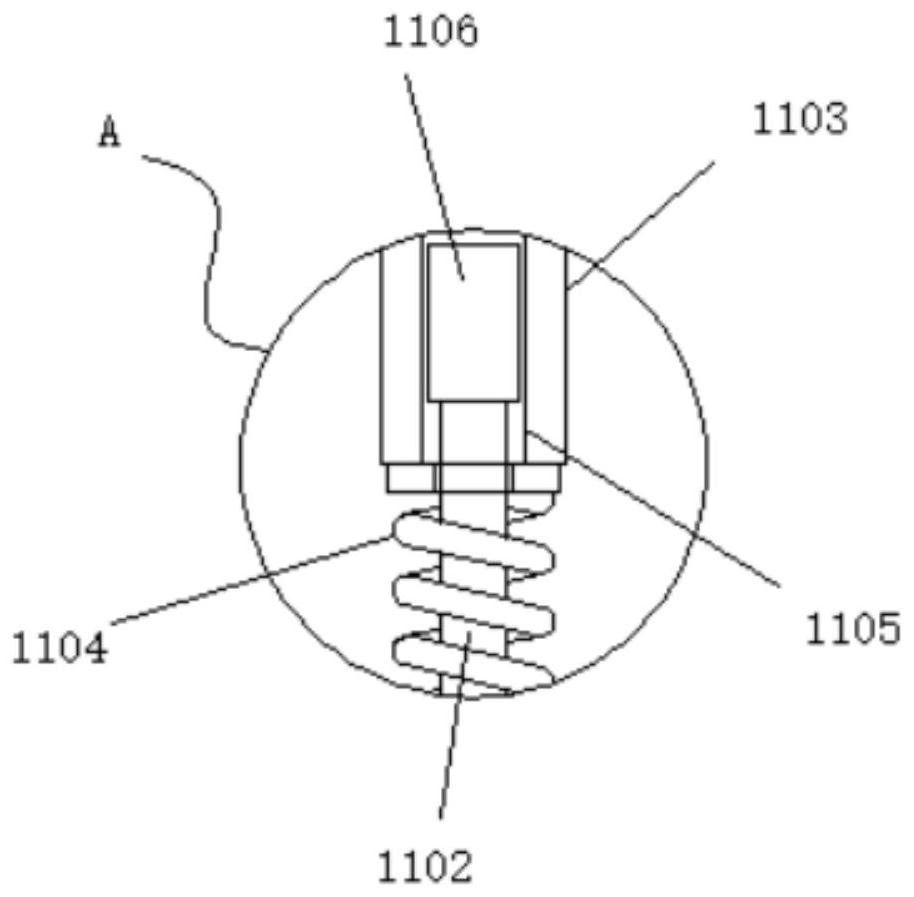

Safe and reliable new energy vehicle charging pile with good waterproof effect

ActiveCN108583319AImprove waterproof performanceIngenious structureCharging stationsElectric vehicle charging technologyNew energyProtection mechanism

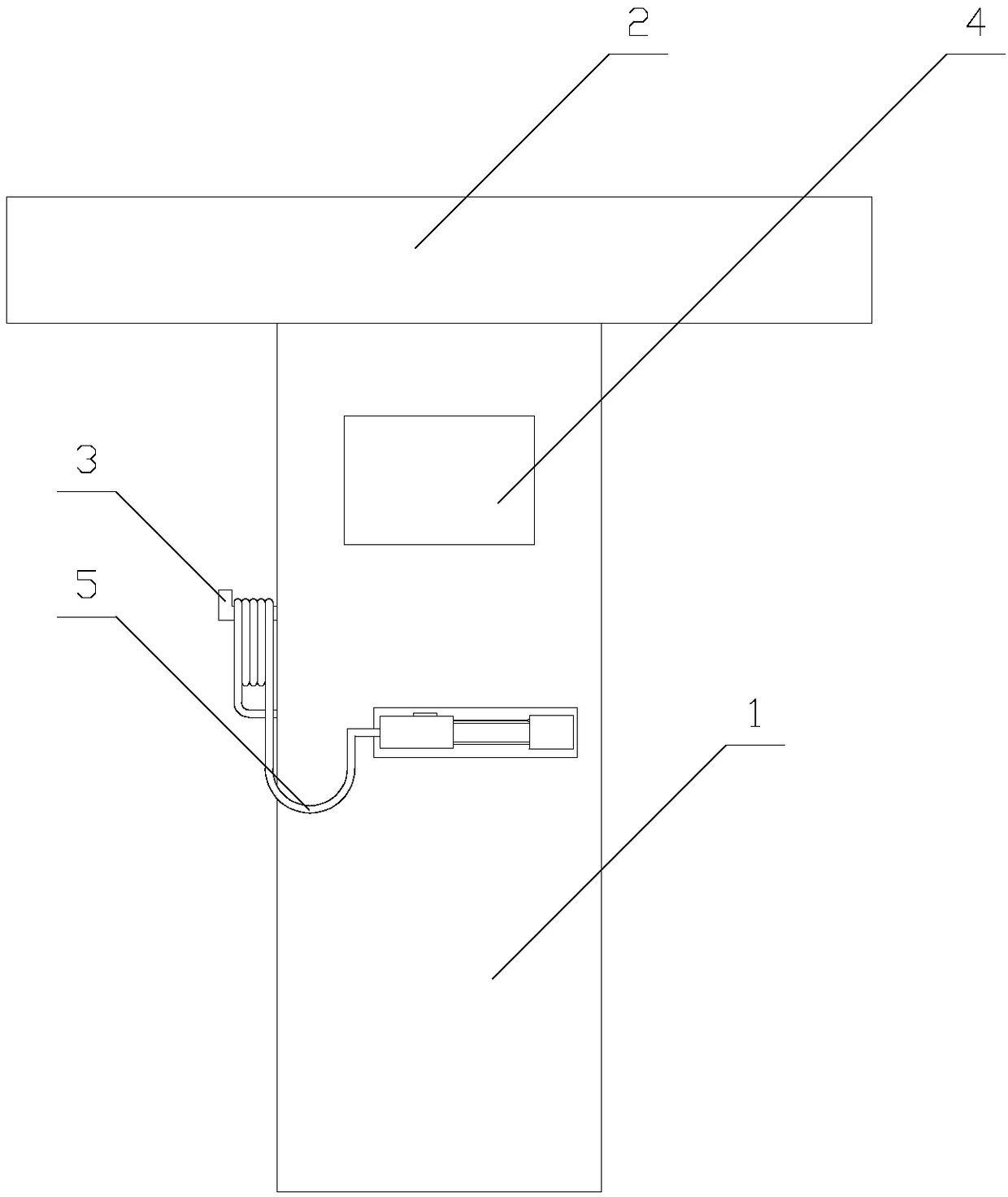

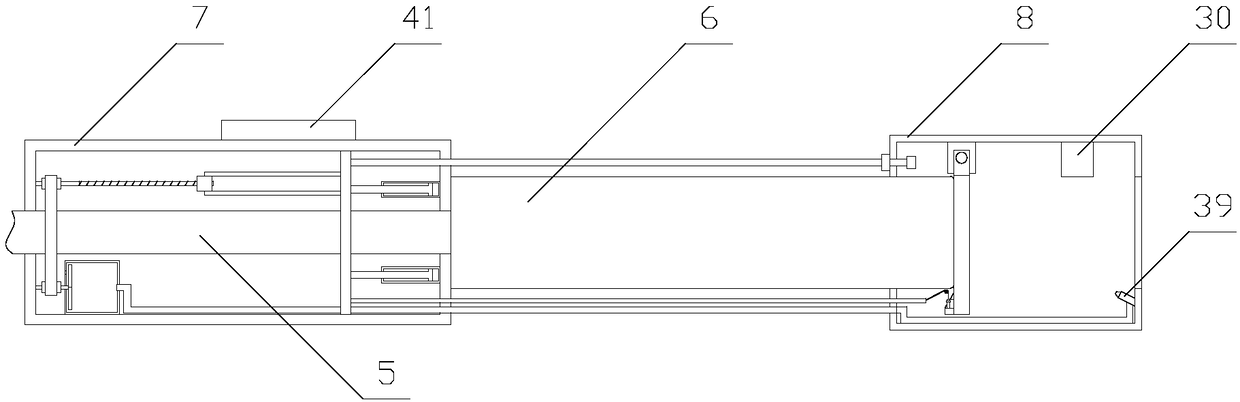

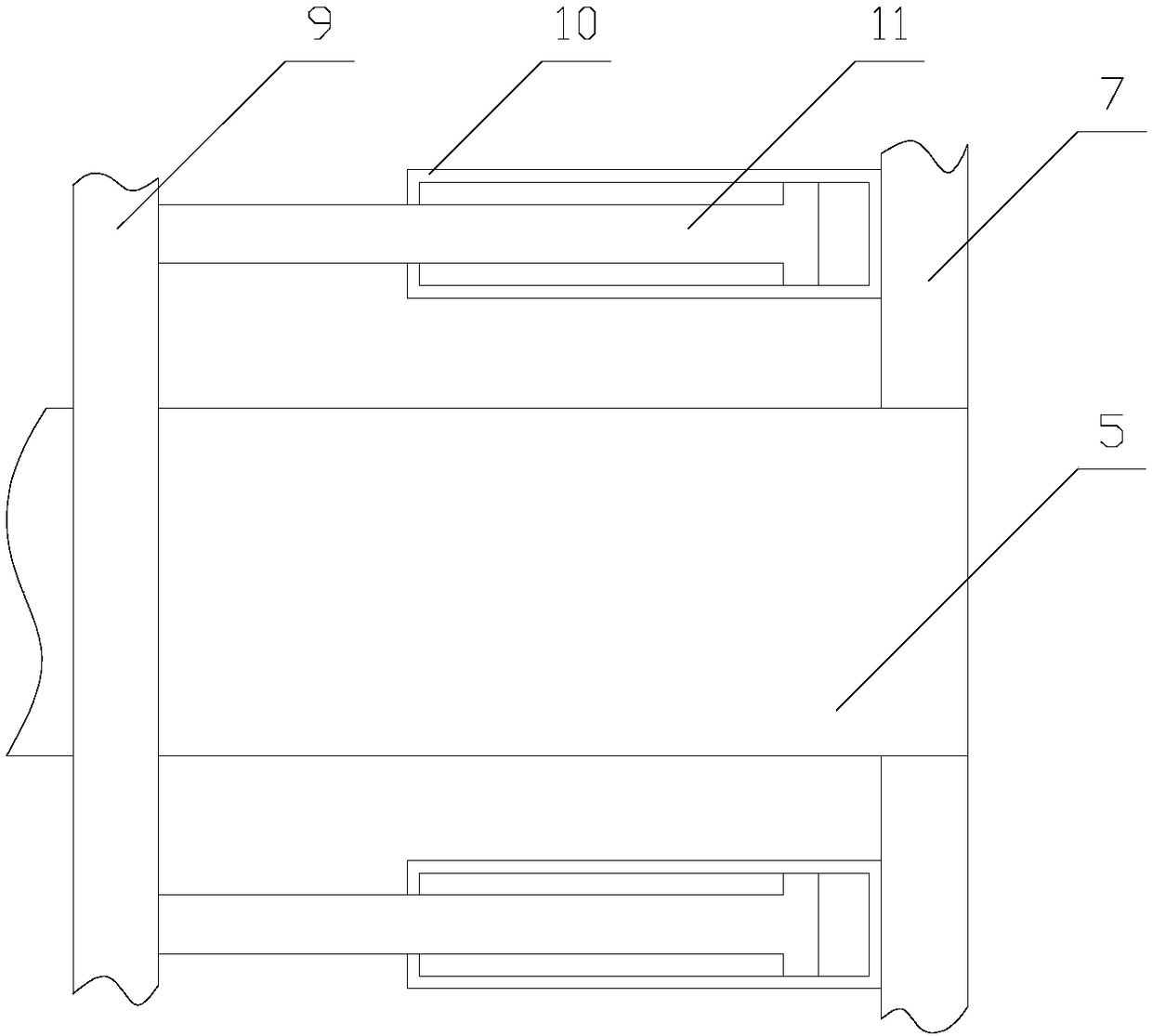

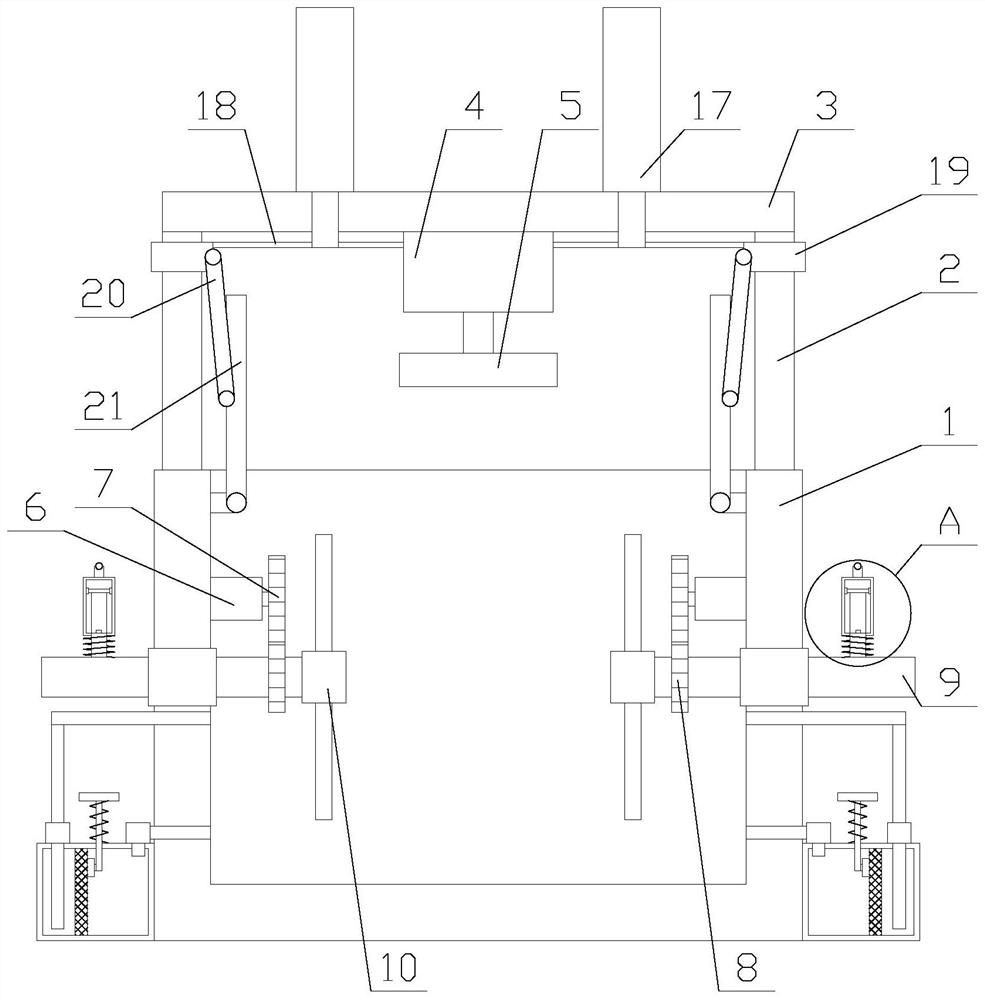

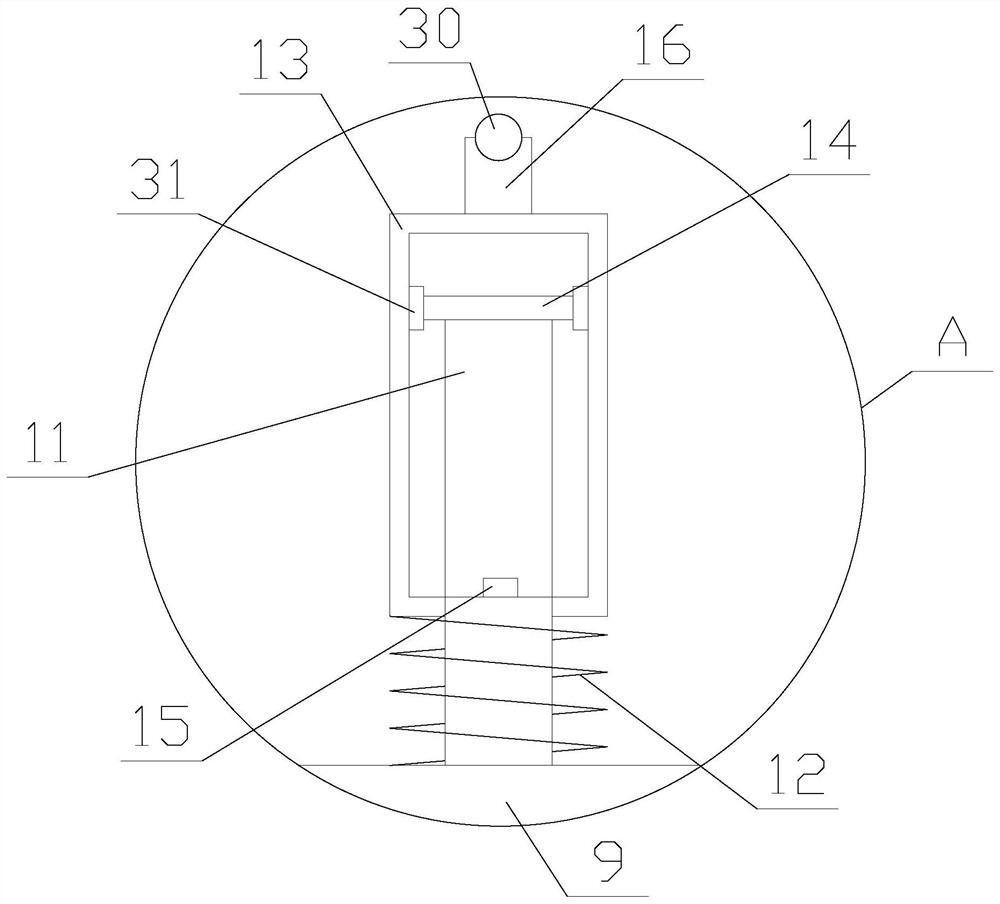

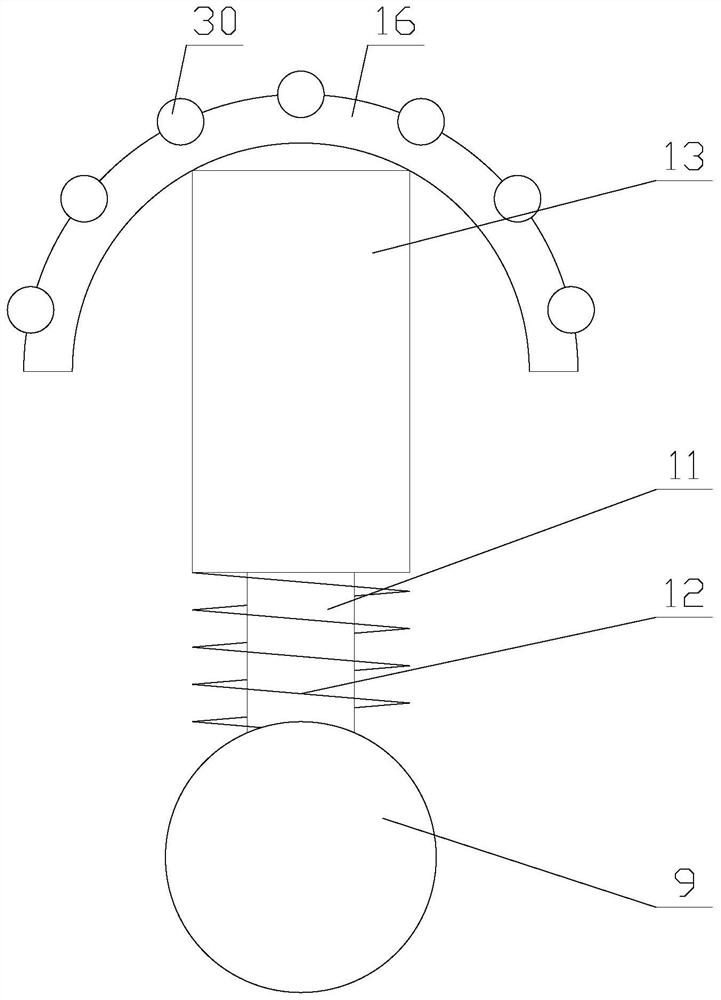

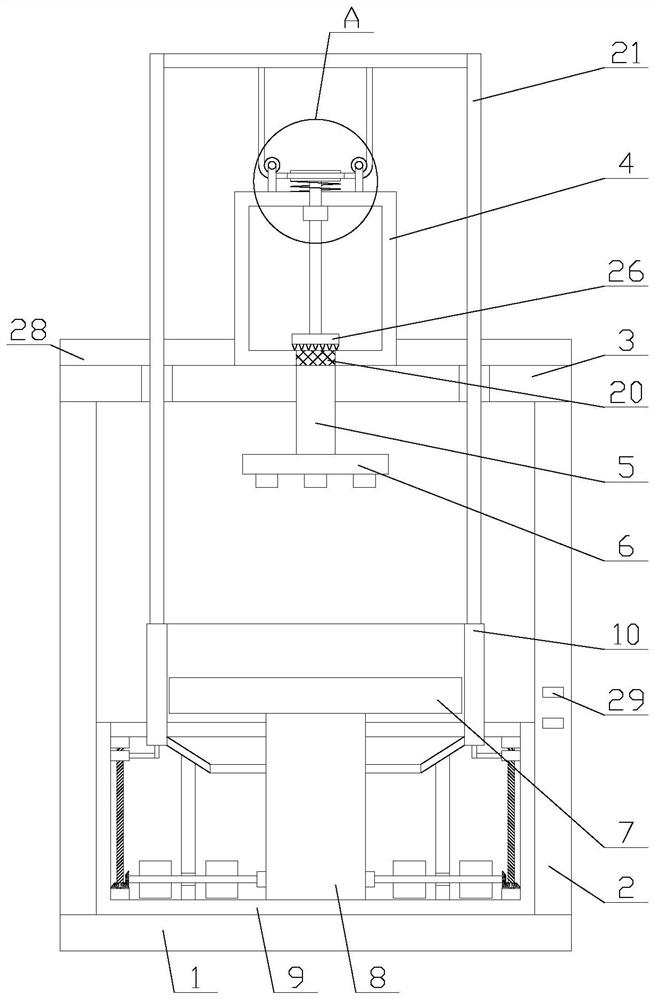

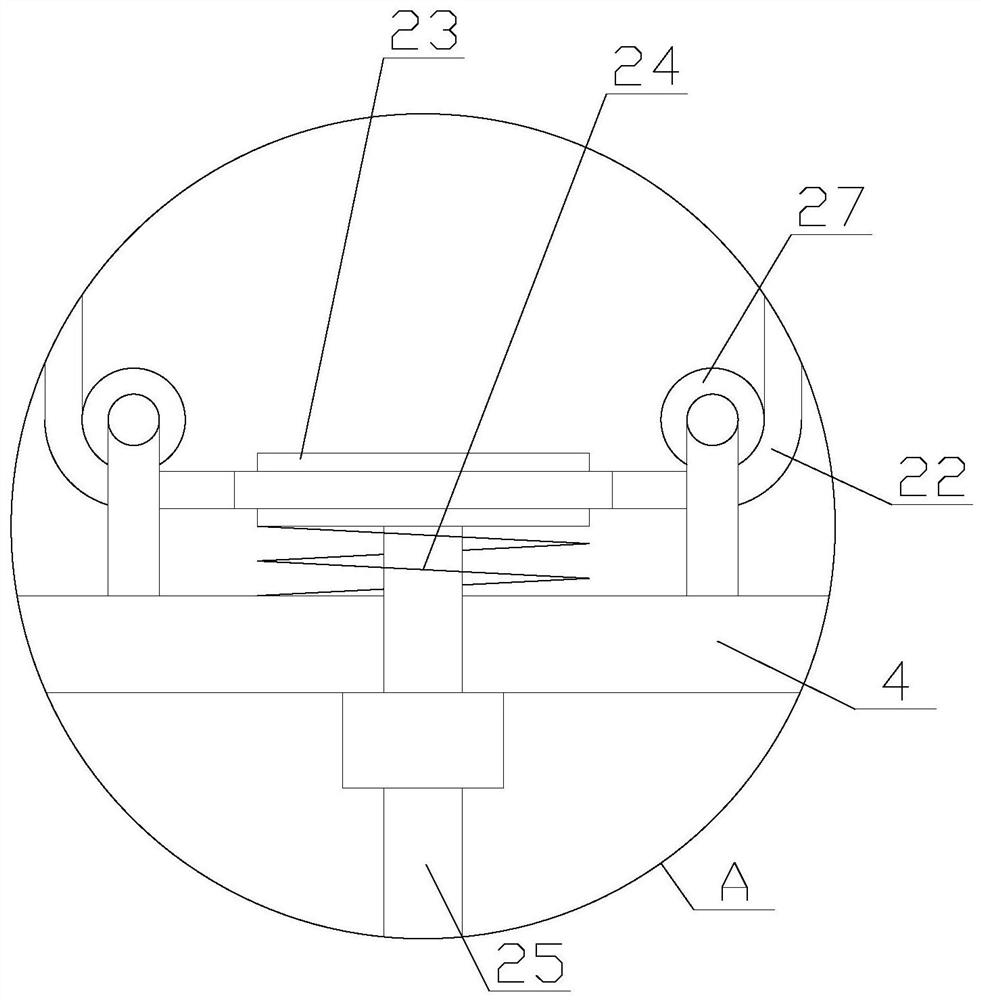

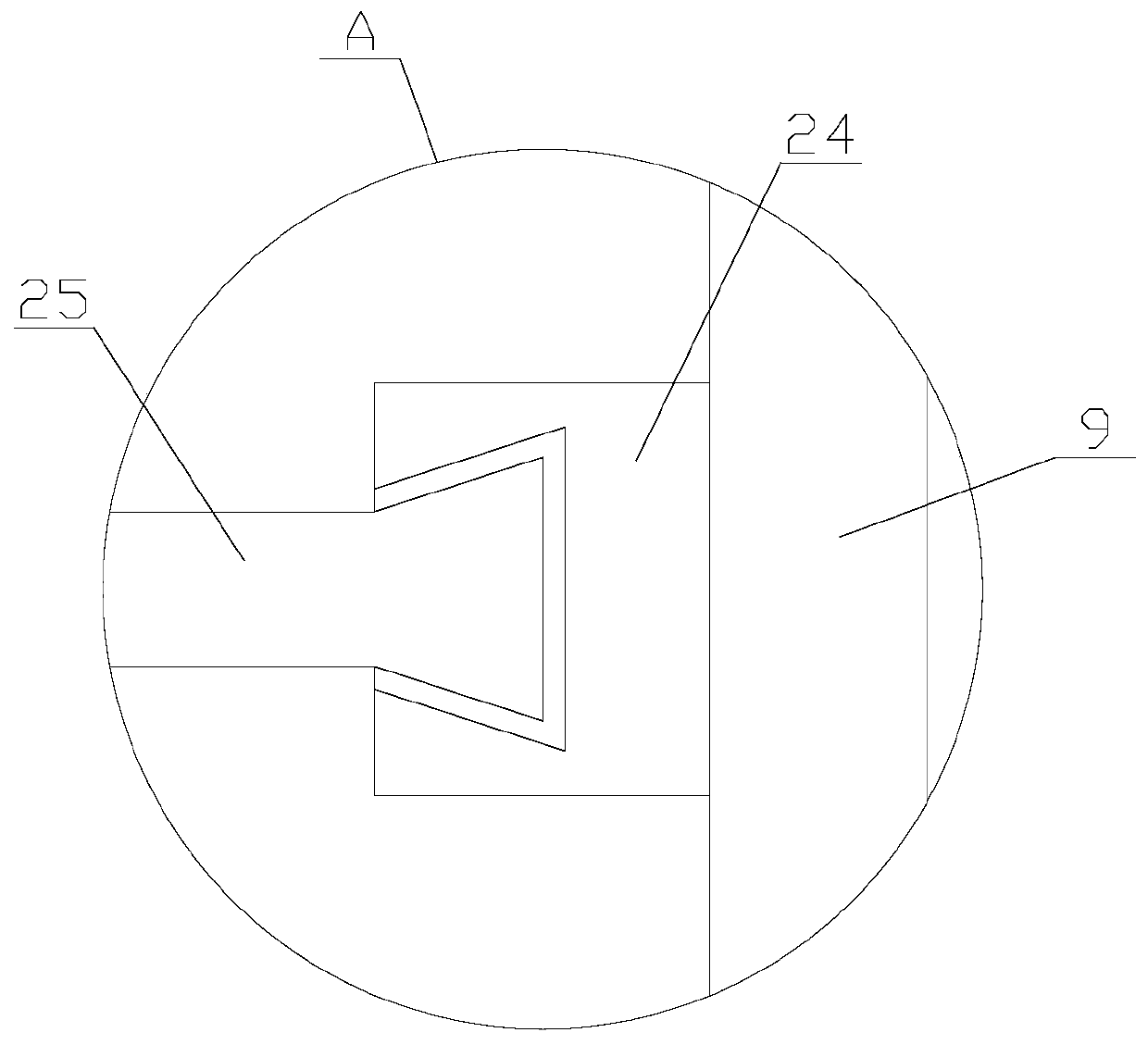

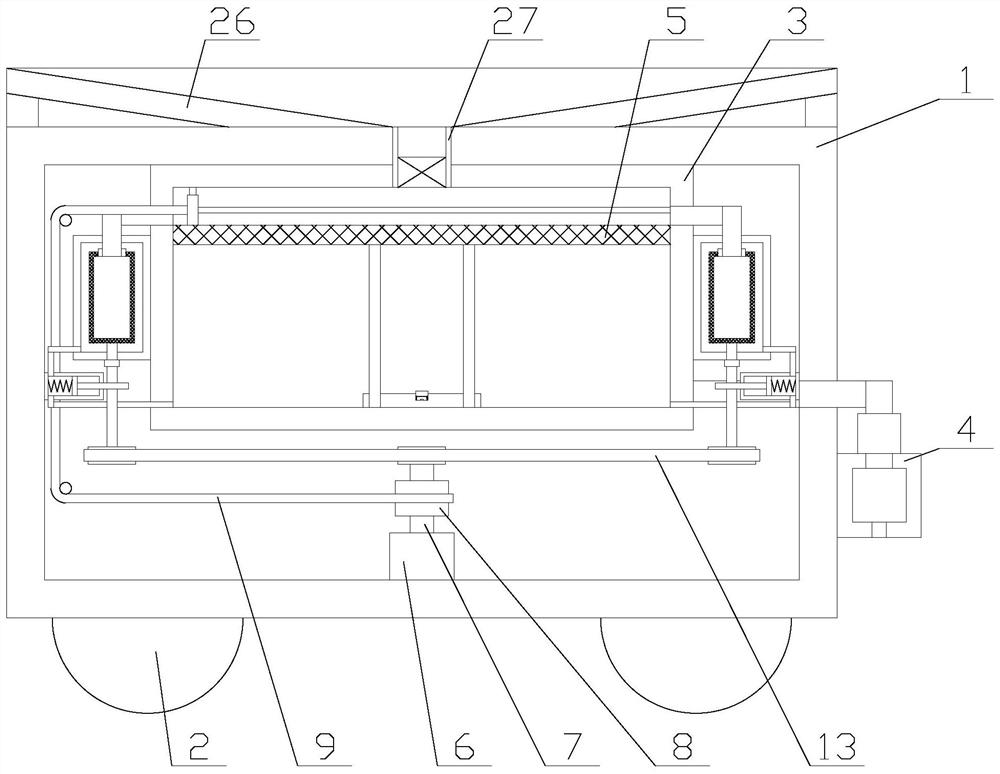

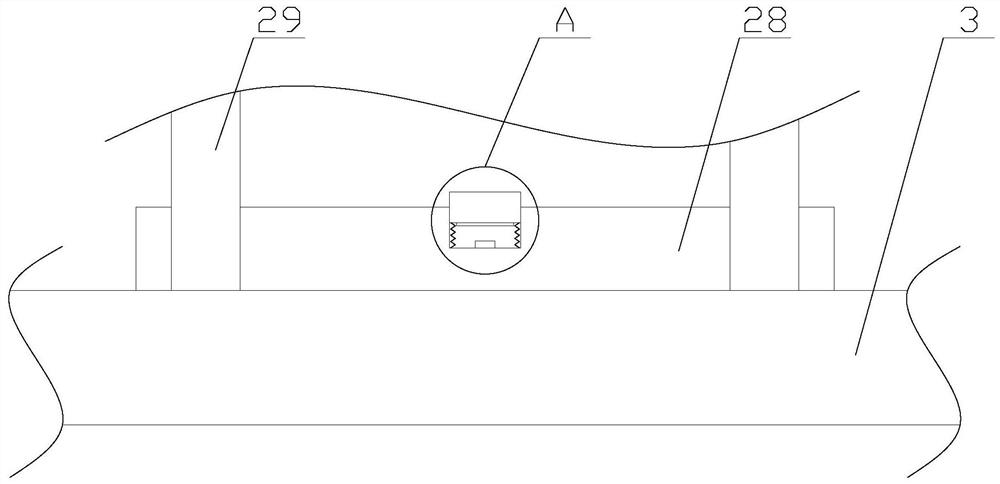

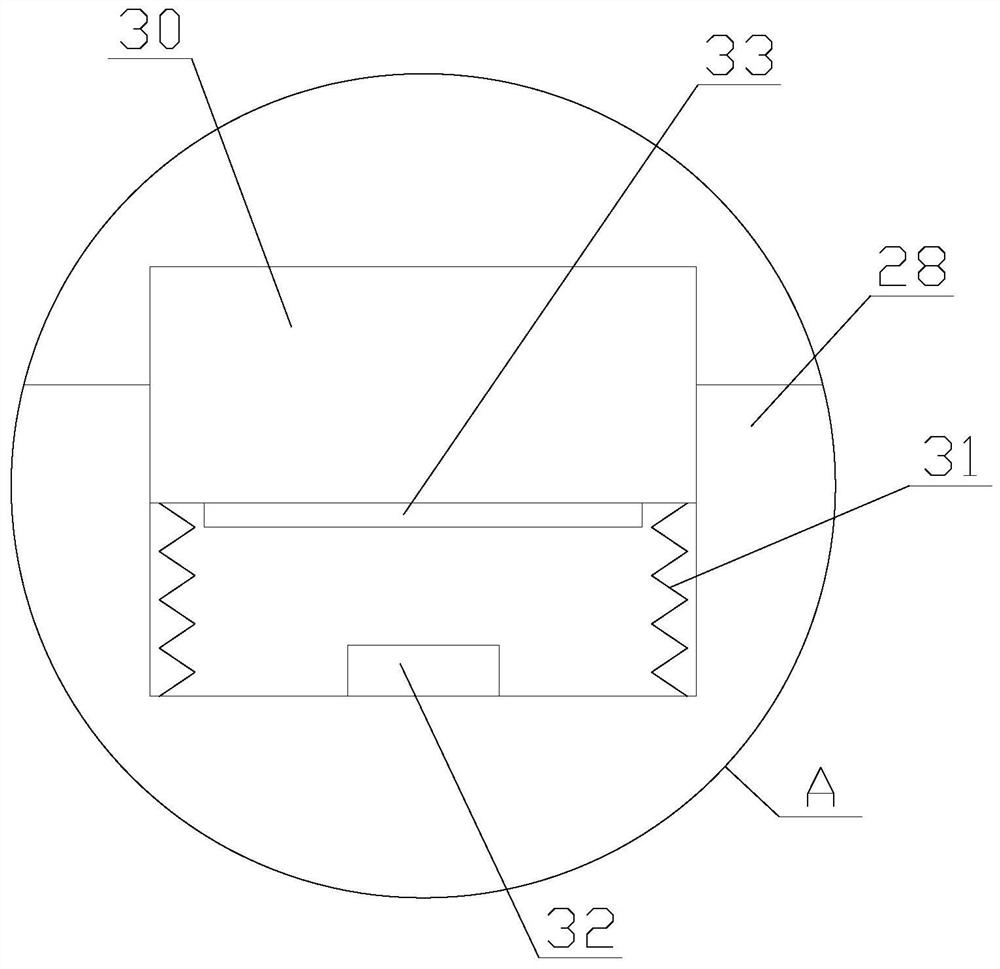

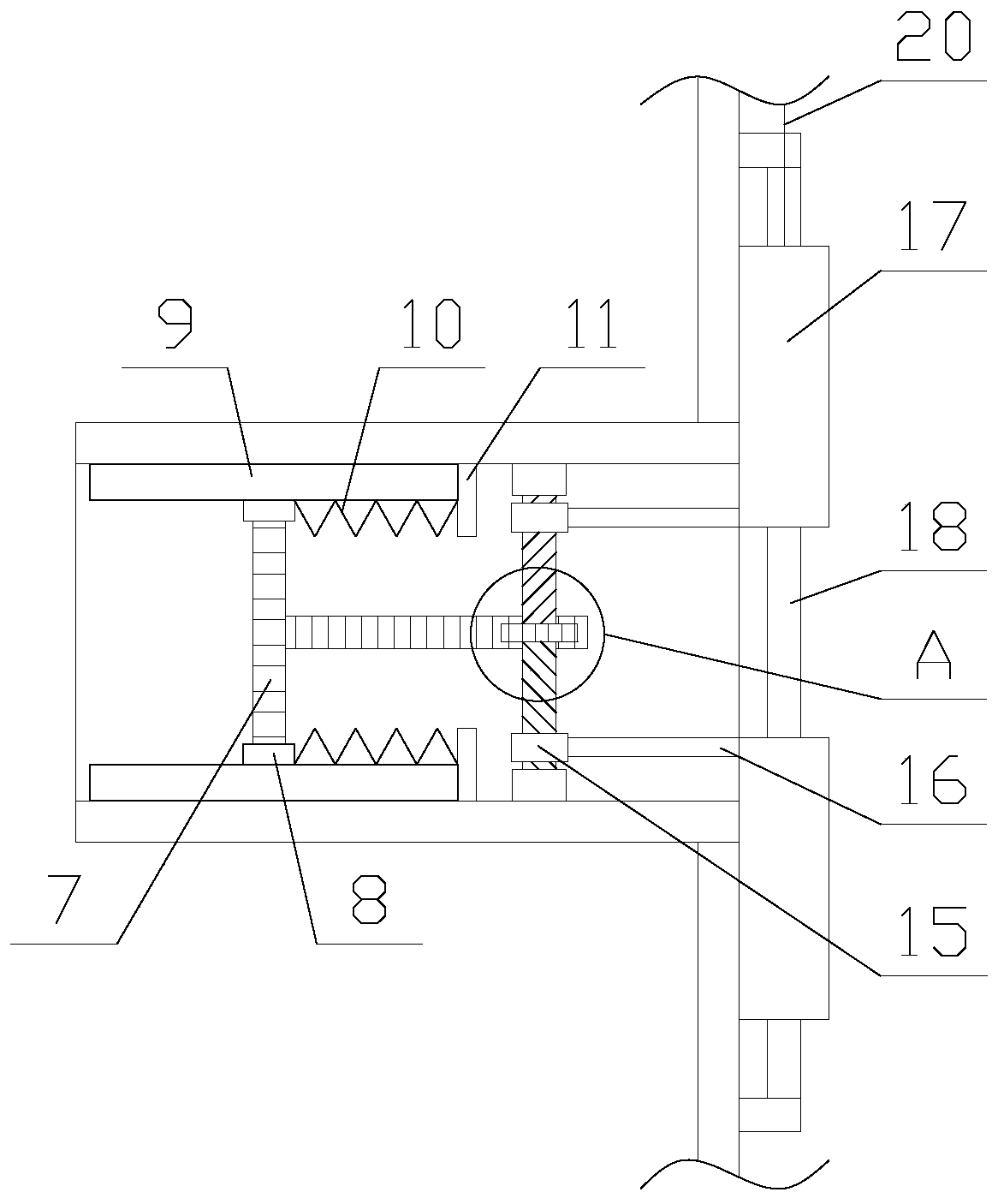

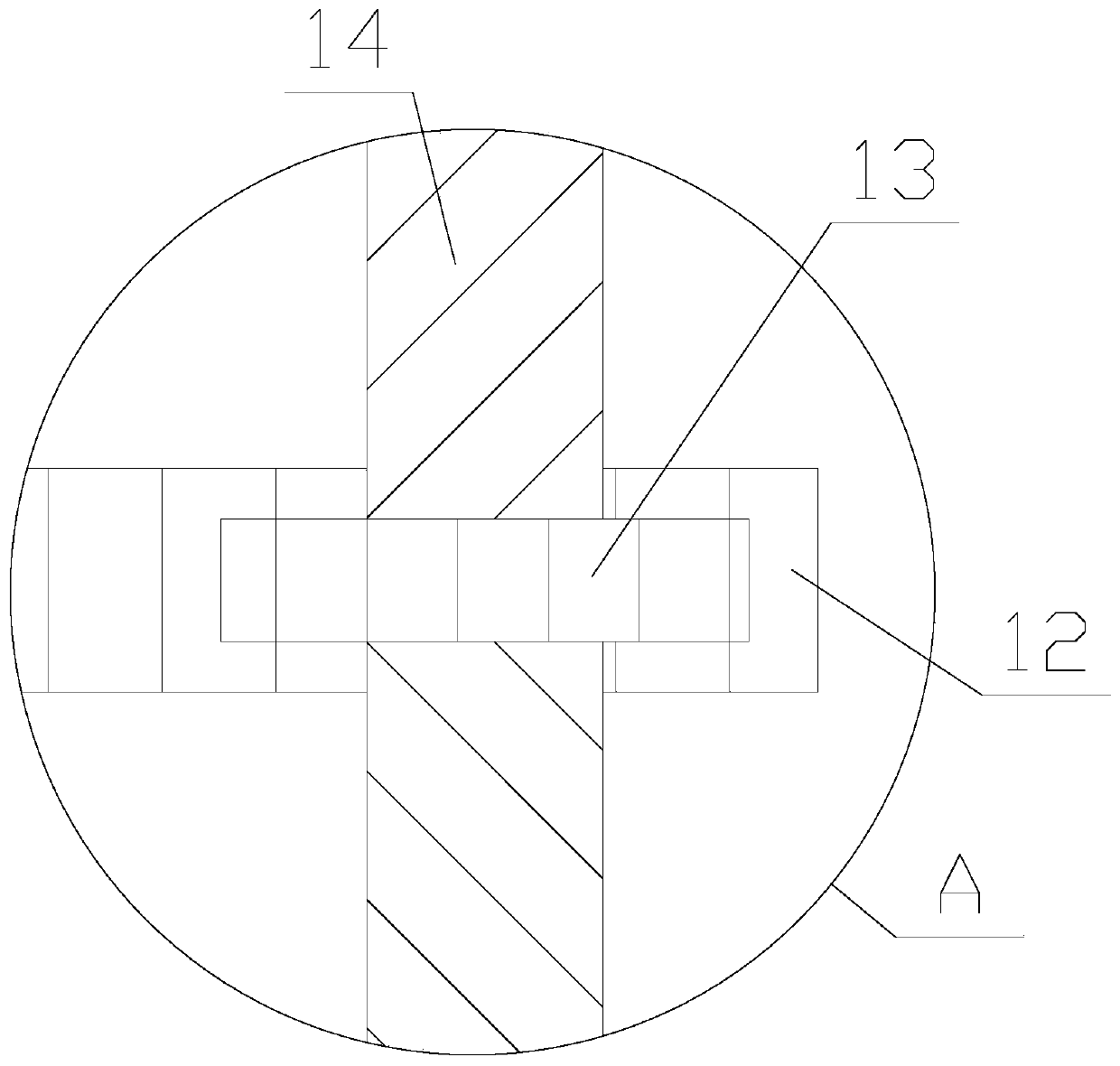

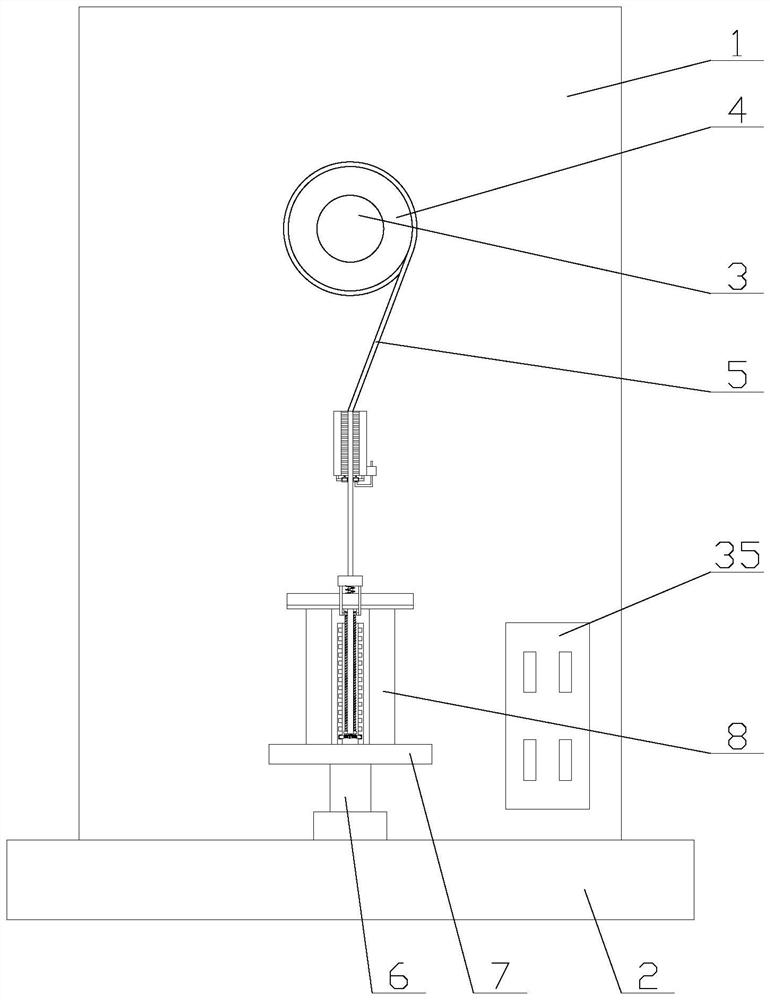

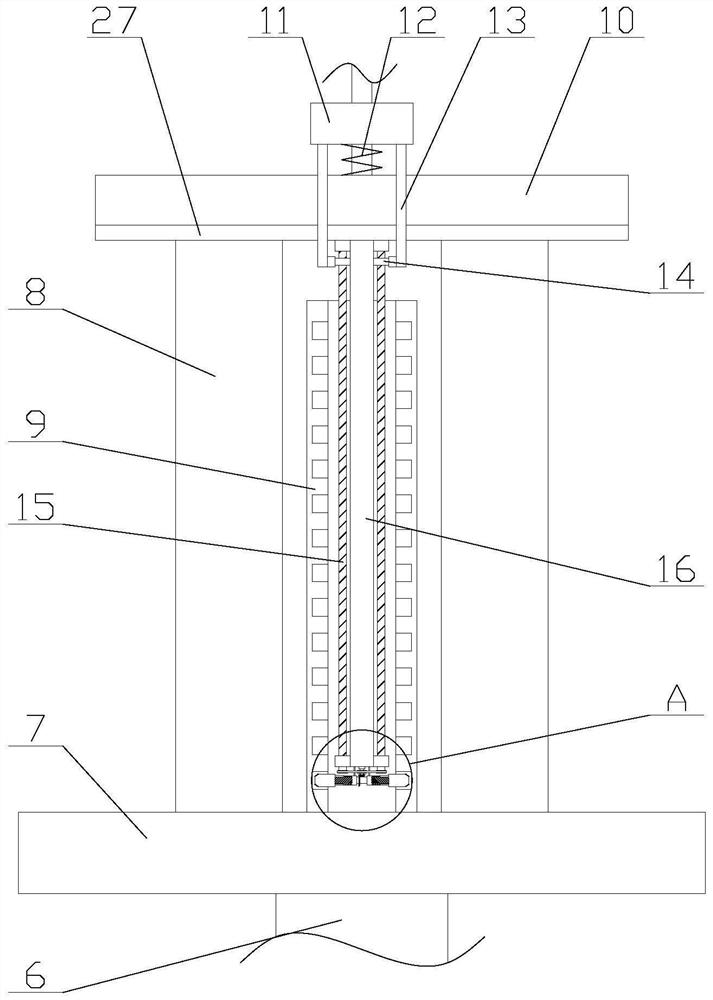

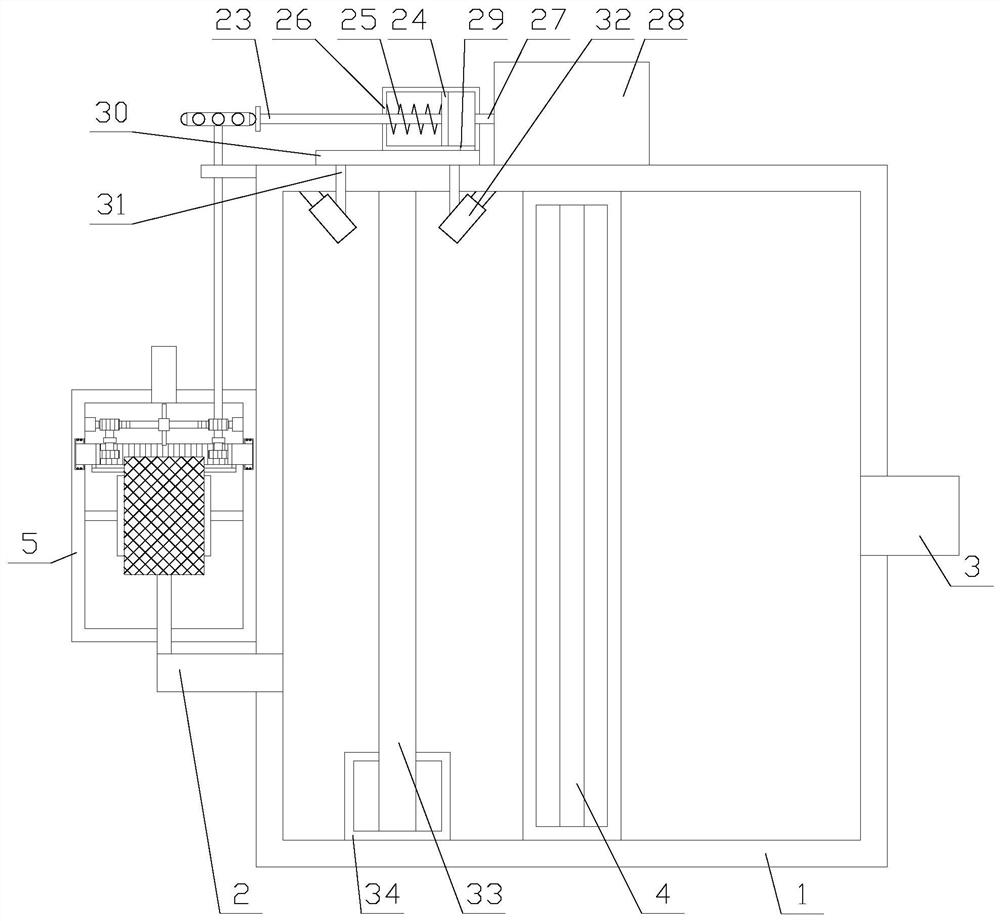

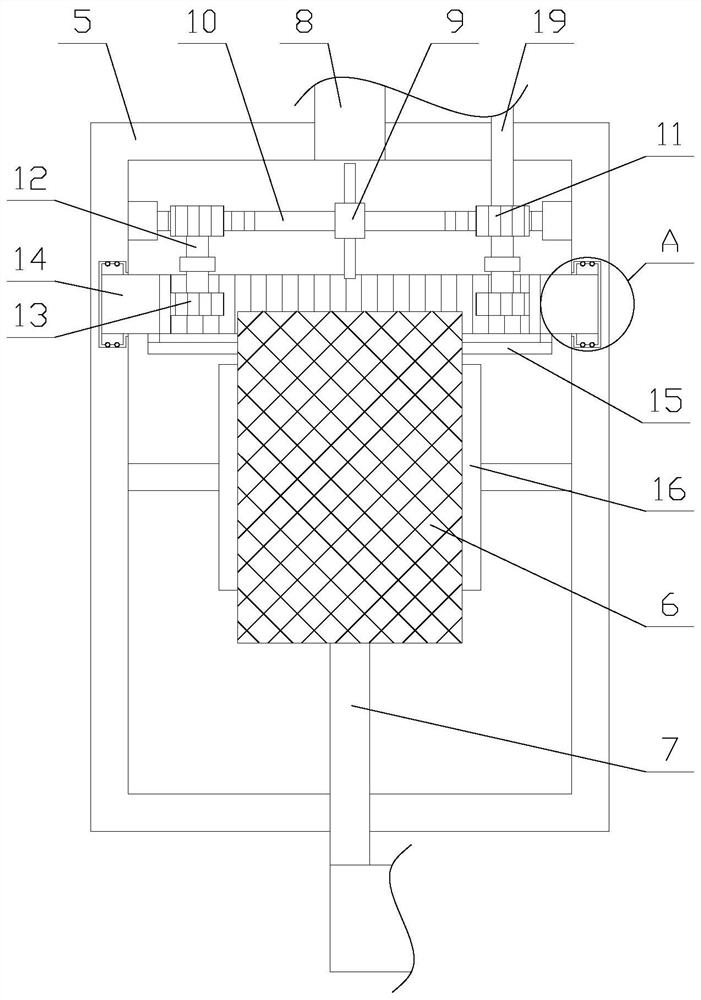

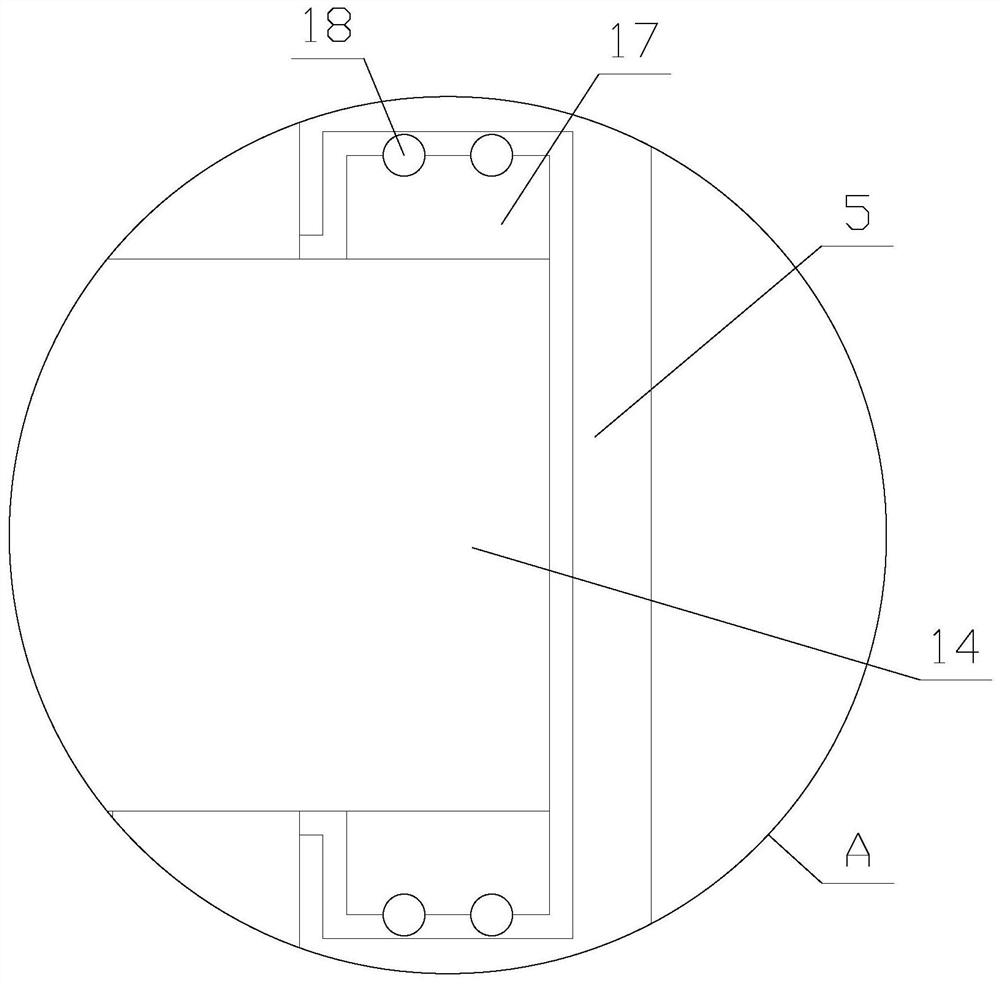

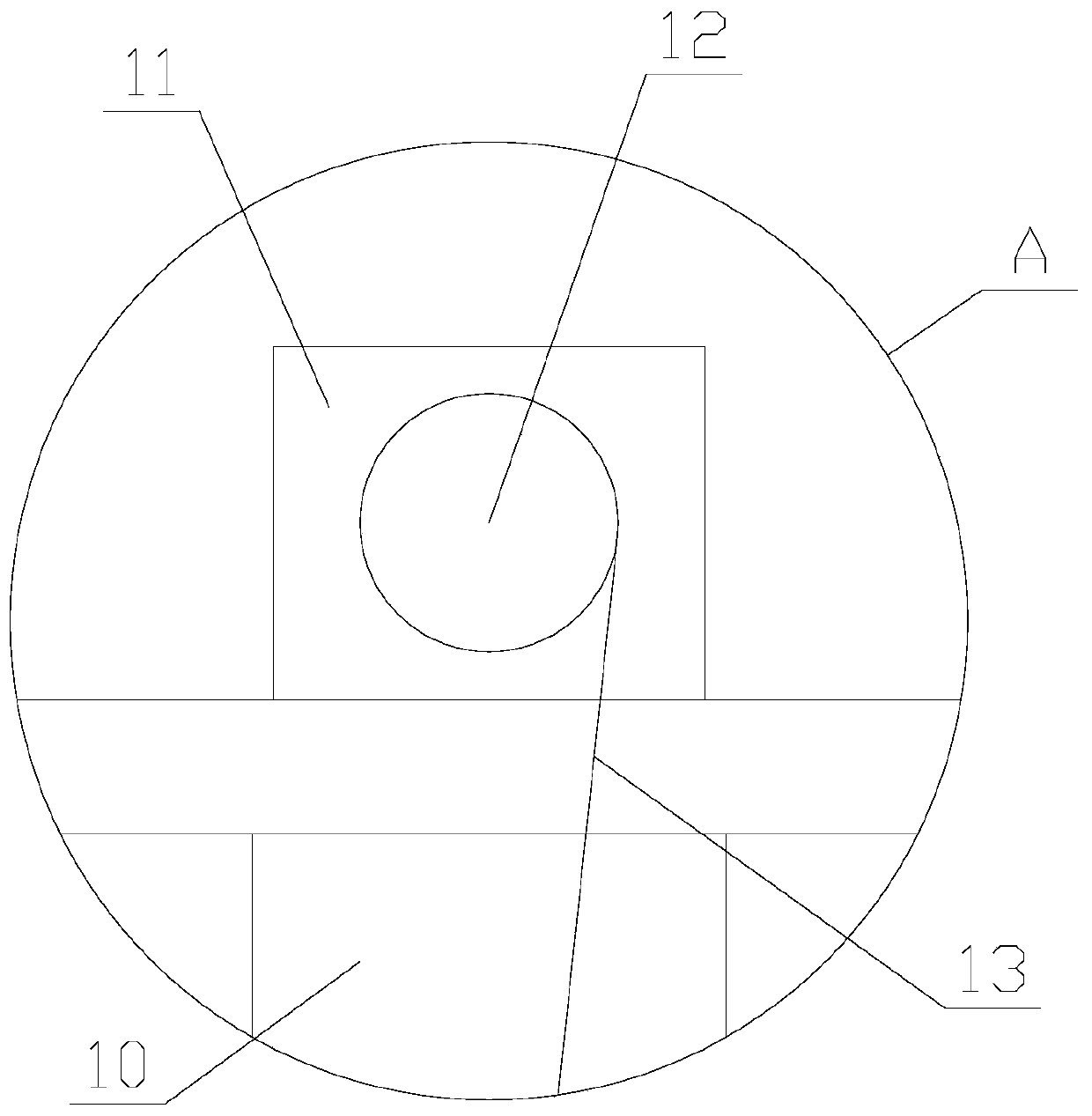

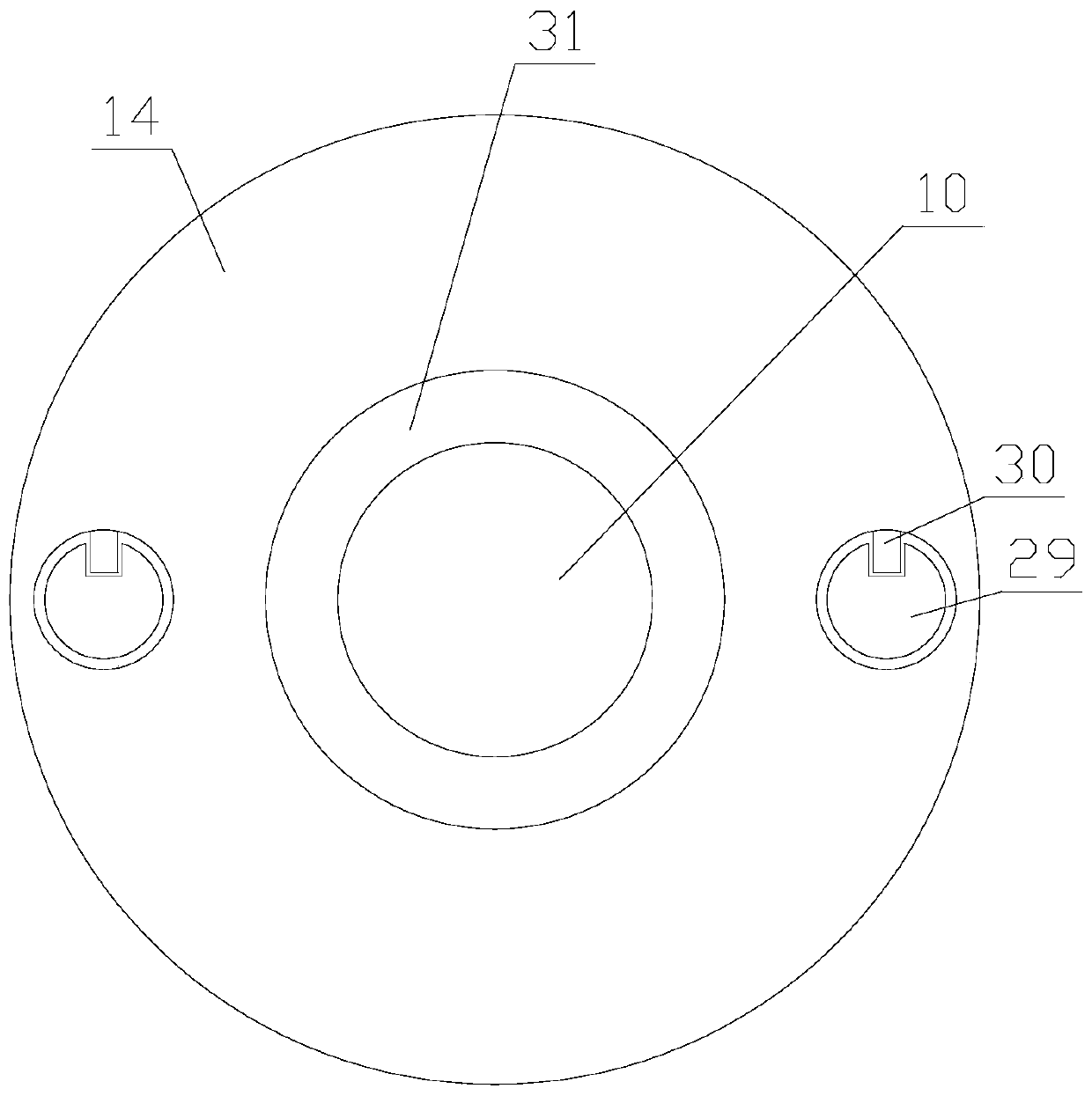

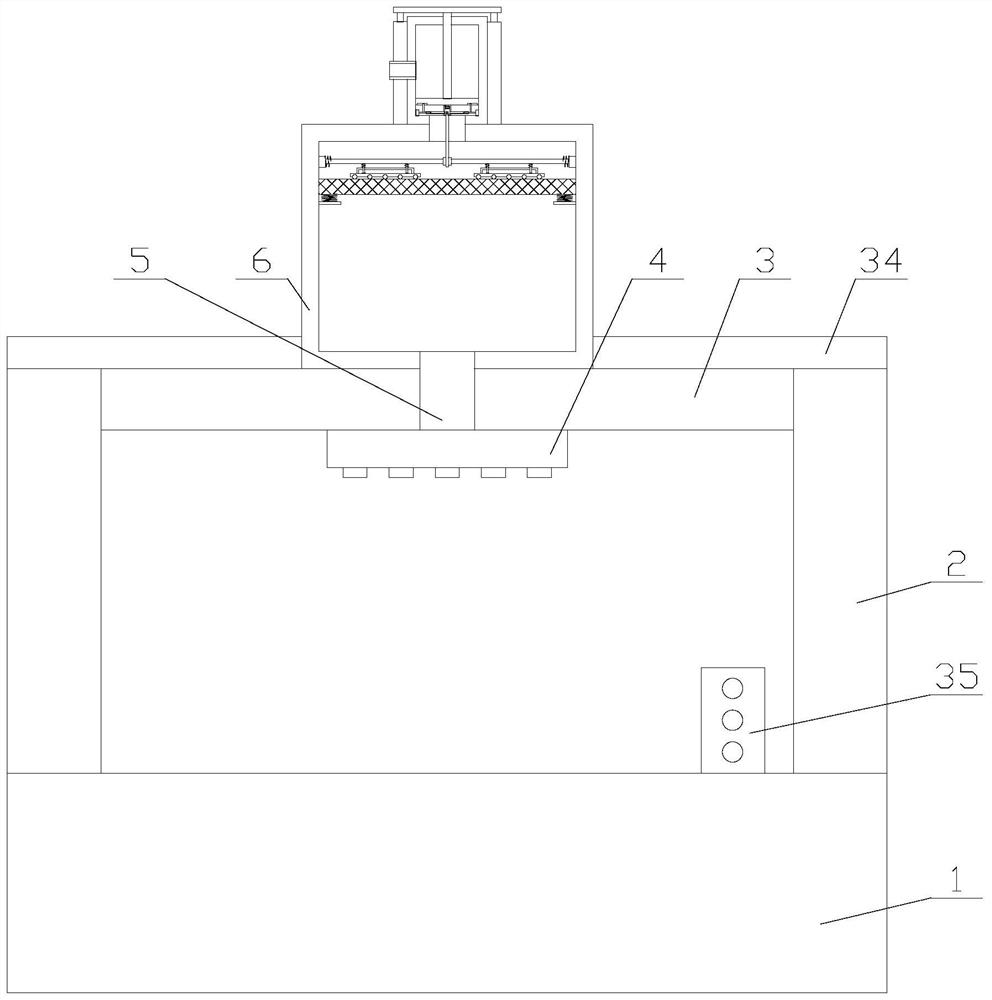

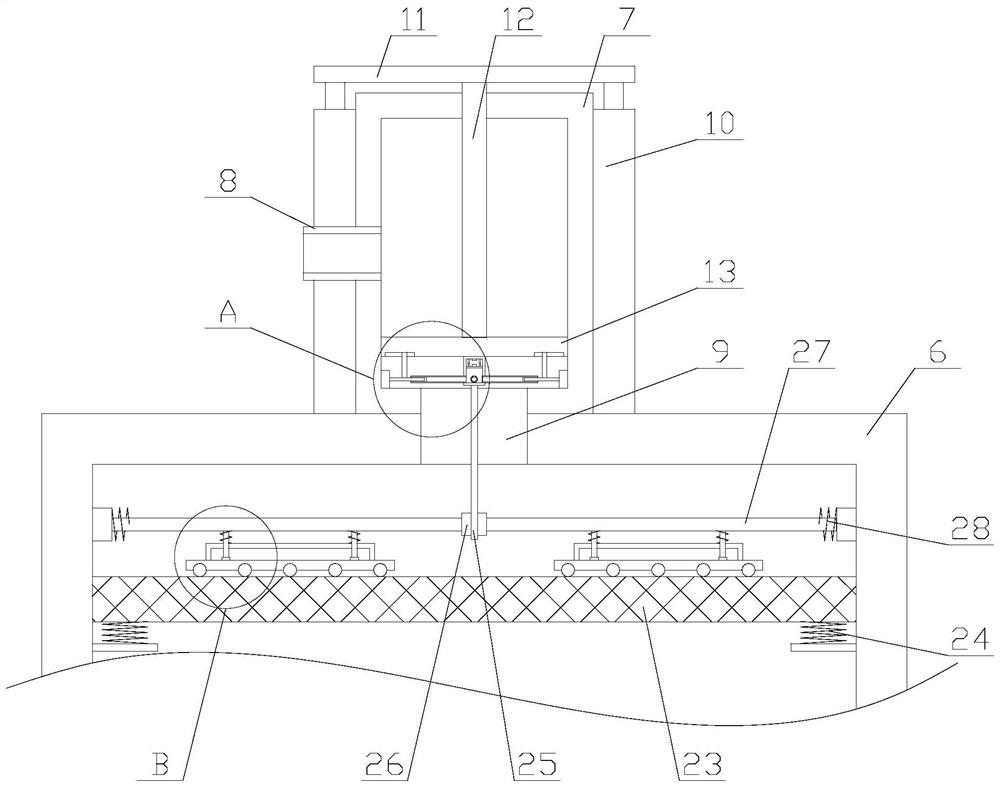

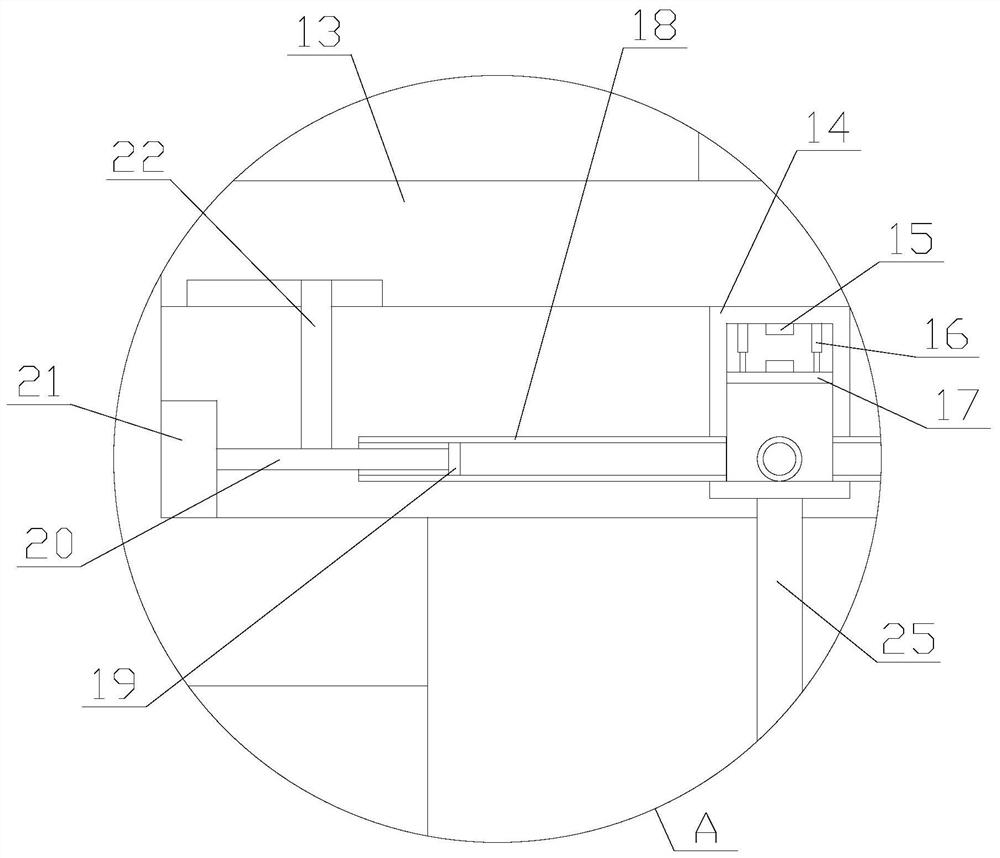

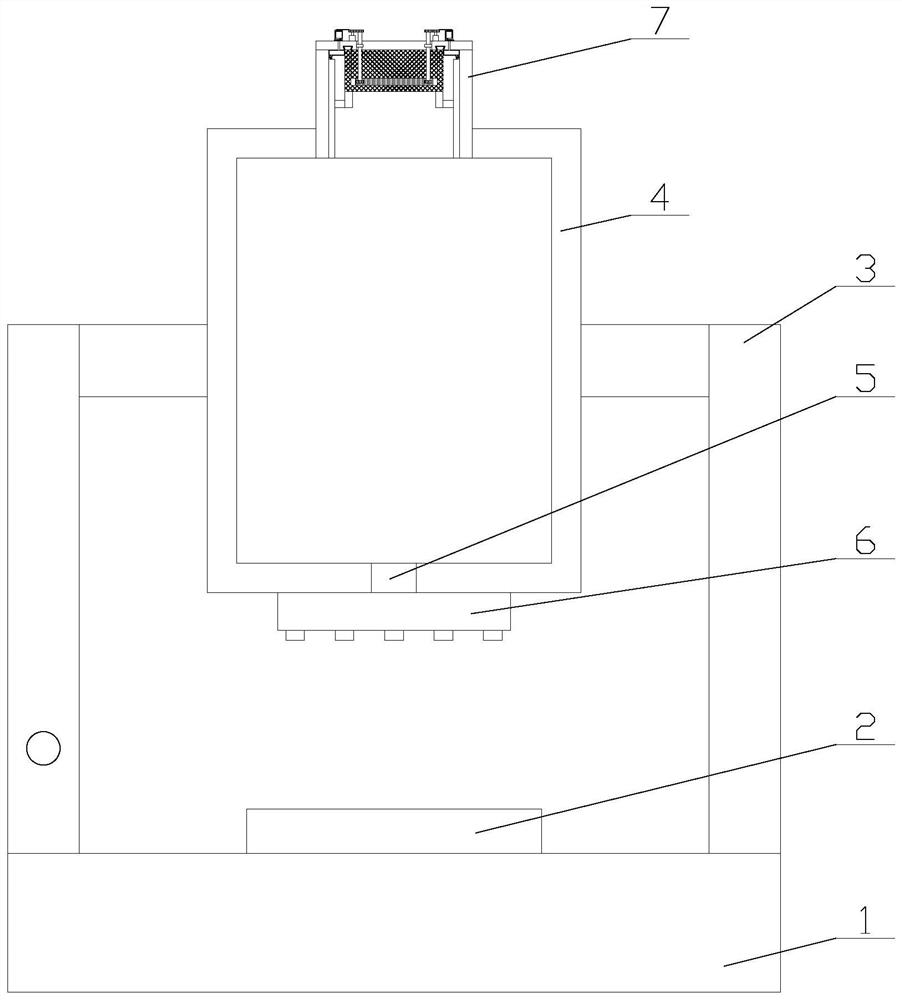

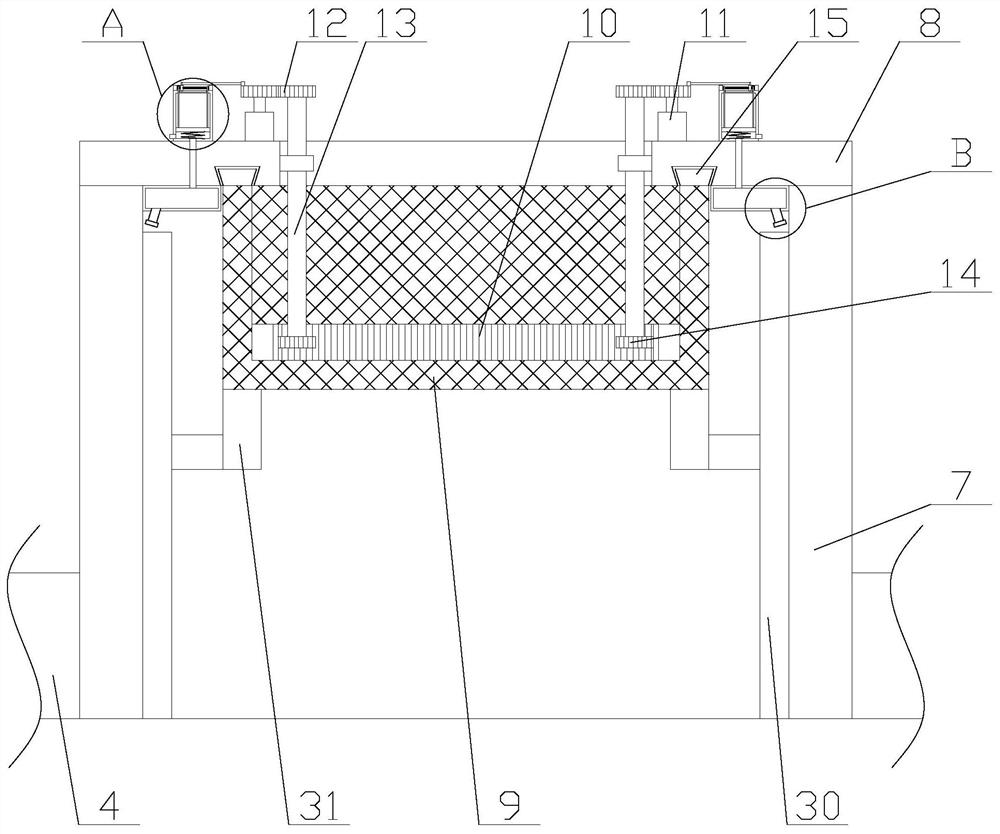

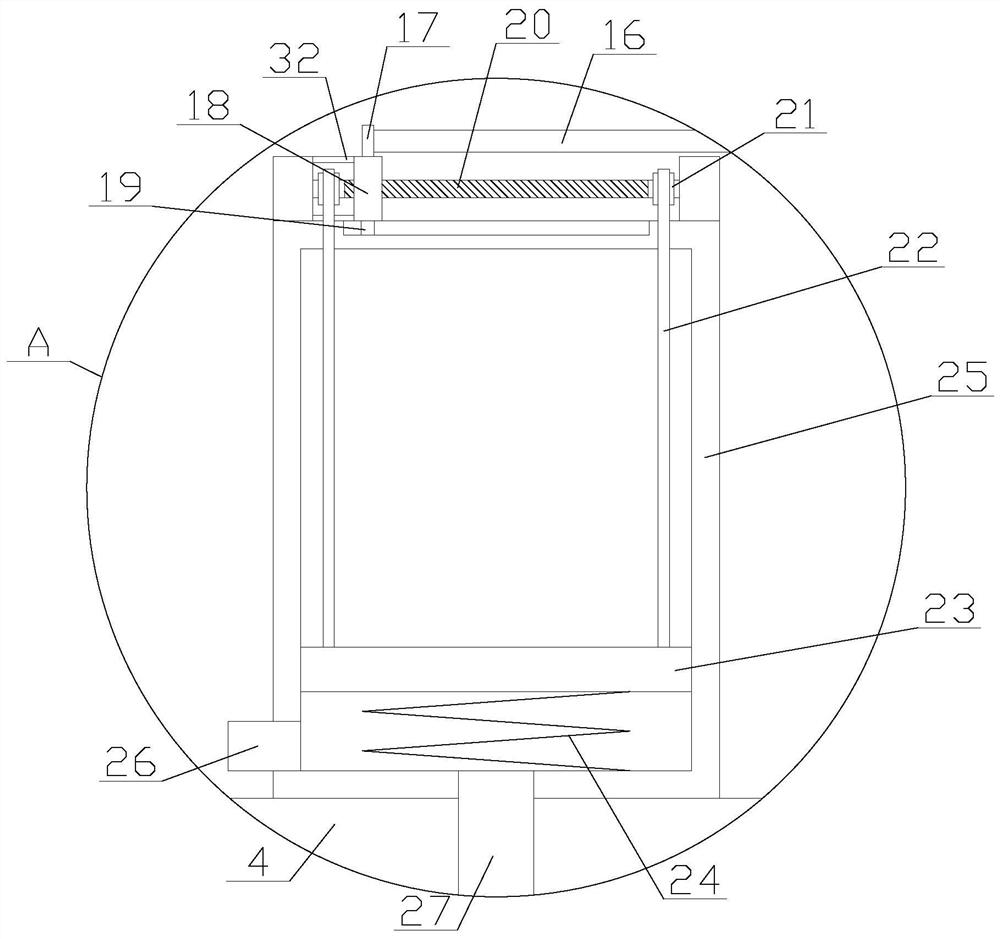

The invention relates to a safe and reliable new energy vehicle charging pile with a good waterproof effect. The safe and reliable new energy vehicle charging pile with the good waterproof effect comprises a main body, a sun visor, a hook, a display screen, a lead and a charging gun; a concave opening is formed in the main body; the charging gun is arranged in the concave opening; the bottom of the sun visor is fixedly connected with the top end of the main body; the hook is fixed on one side of the main body; the charging gun is connected with the main body through a lead; the lead is arranged on the hook; the display screen is arranged on the main body; a waterproof mechanism and a protection mechanism are arranged on the charging gun; the waterproof mechanism comprises a connecting box,a protection box, a driving assembly, an unlocking assembly and a waterproof assembly; and the driving assembly comprises a mobile plate and two driving units. According to the safe and reliable newenergy vehicle charging pile with the good waterproof effect, through adoption of the waterproof mechanism, rainwater is prevented from entering the charging gun; and through adoption of the protection mechanism, a function of eliminating impurities is also realized.

Owner:QINGDAO SONLI SOFTWARE INFORMATION TECH

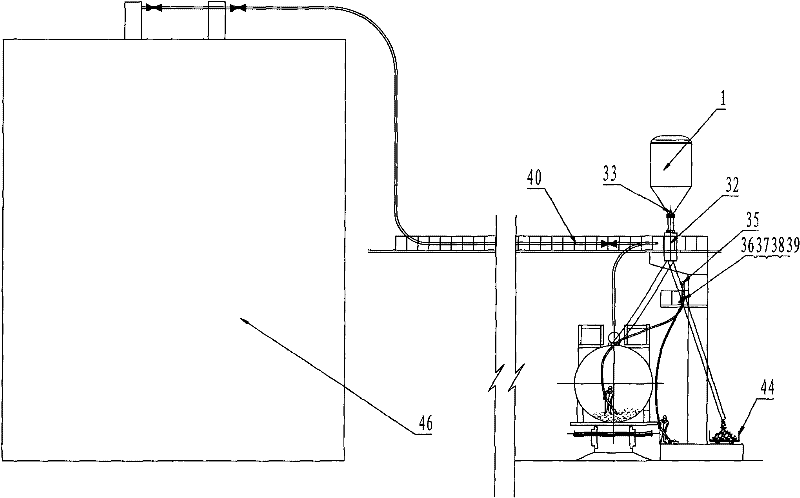

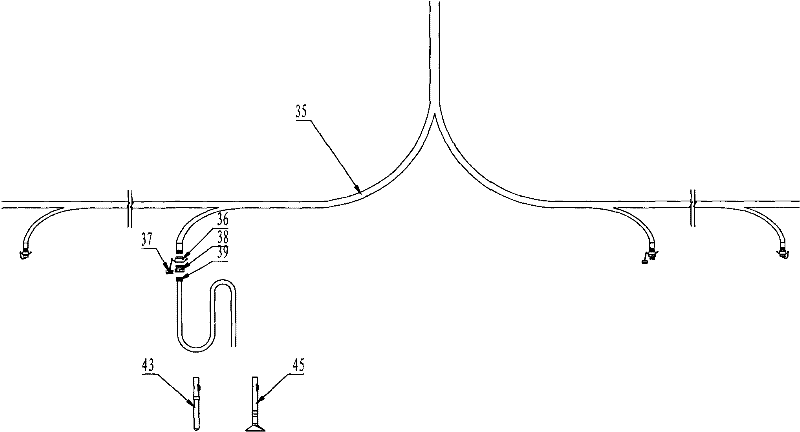

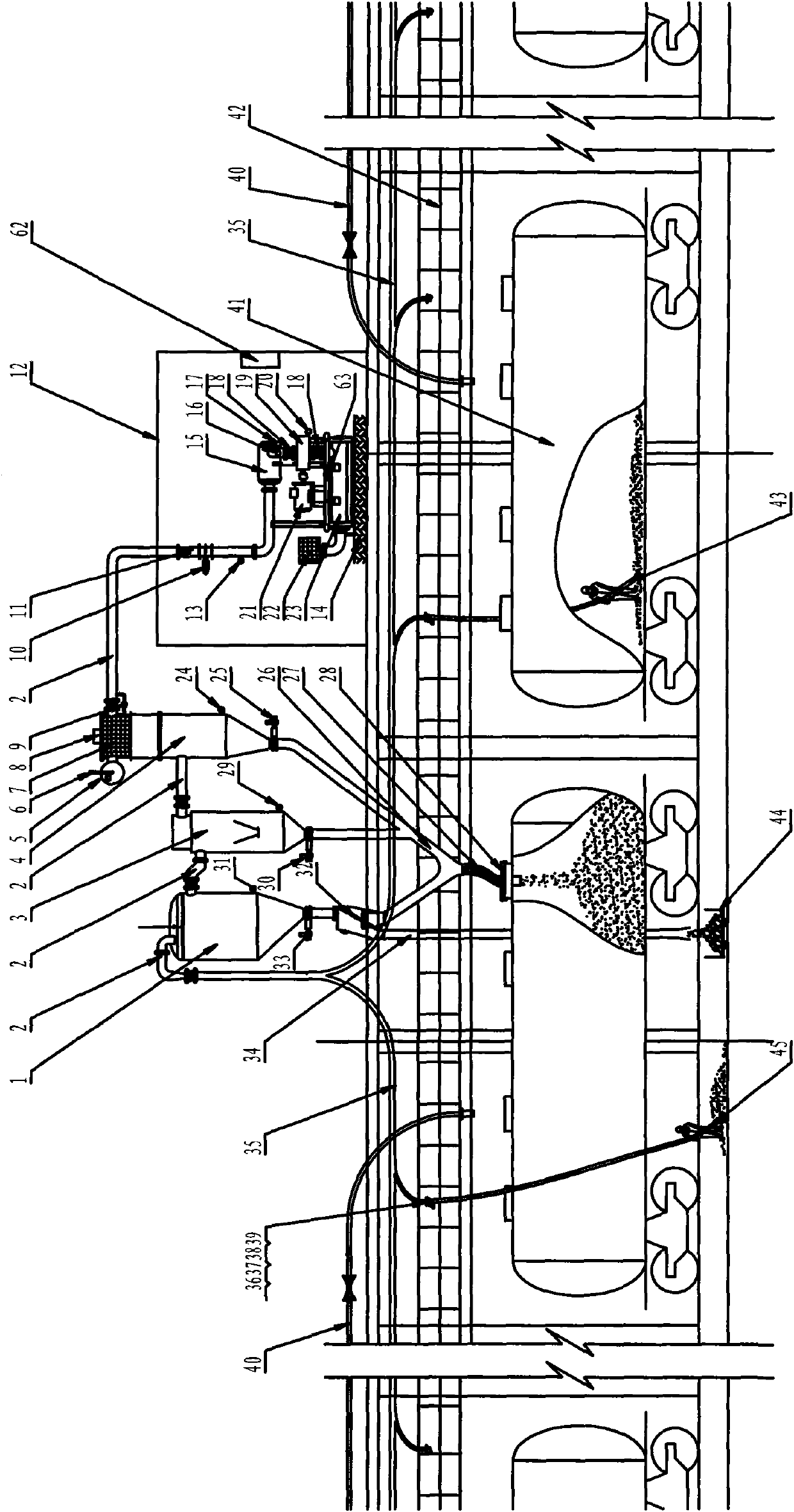

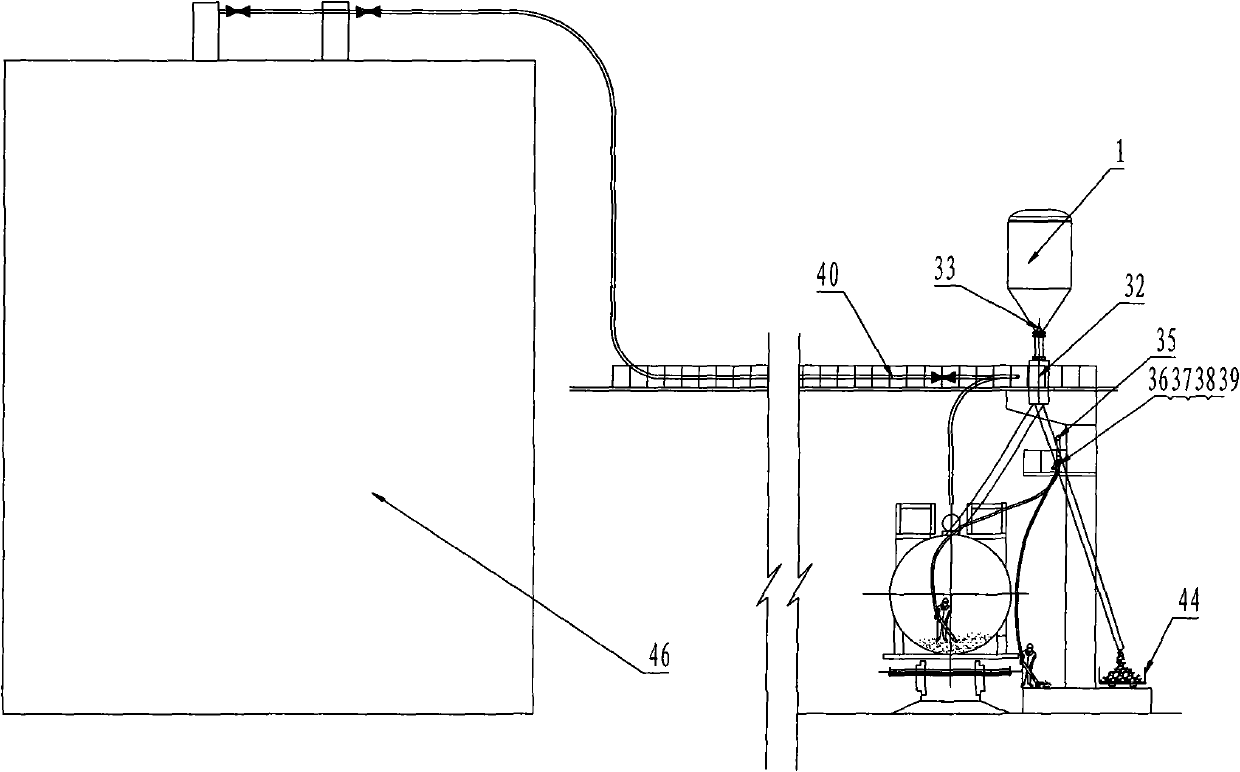

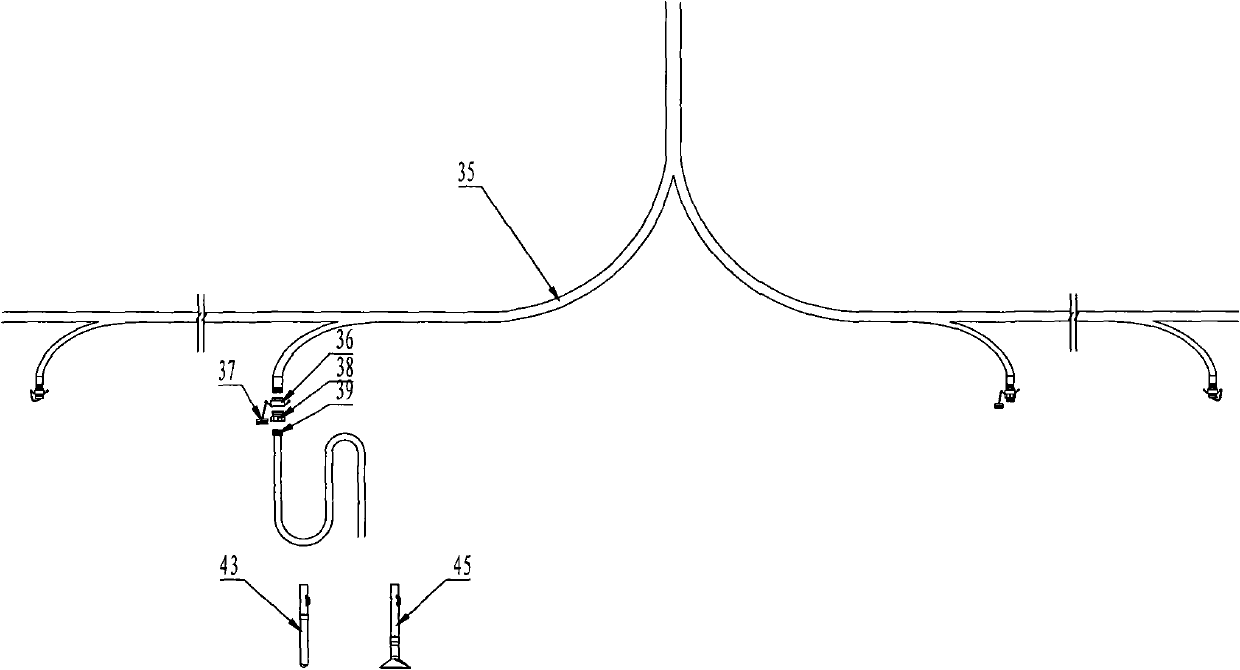

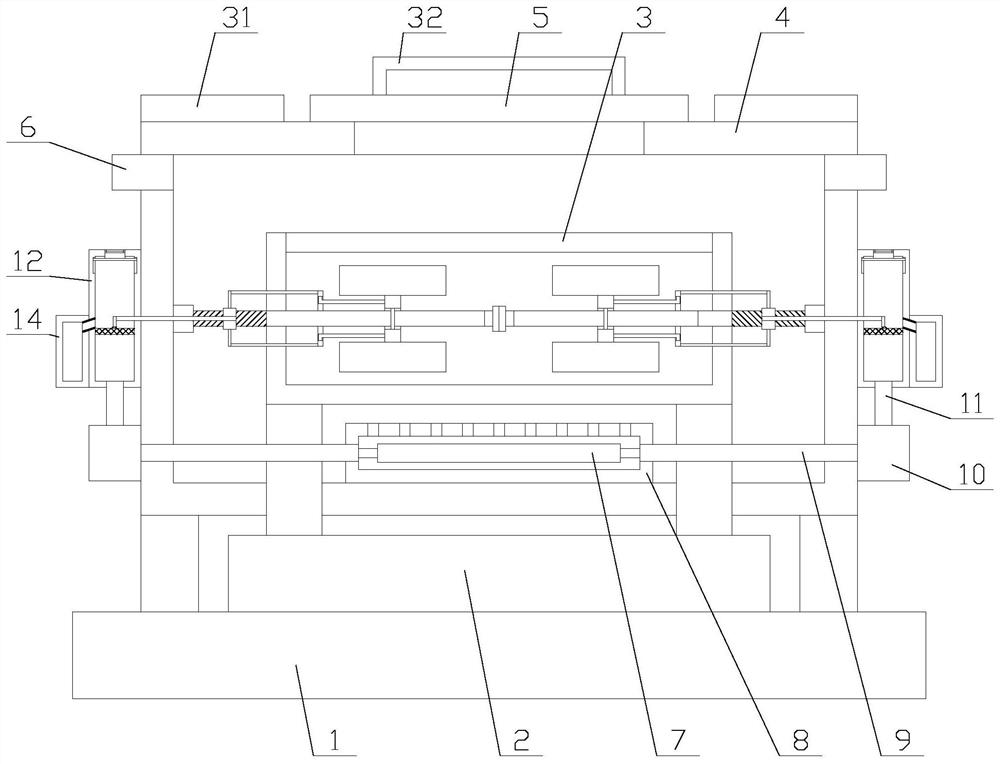

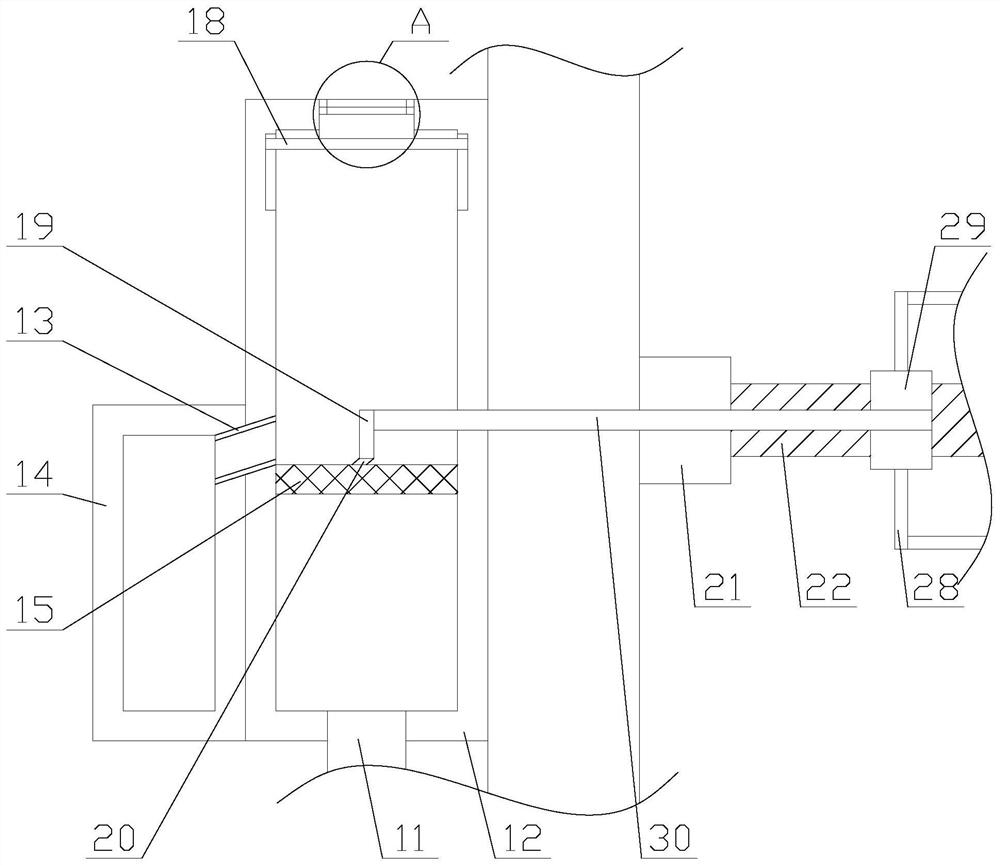

Method and device for recovering residual material and collecting dust at alumina unloading station

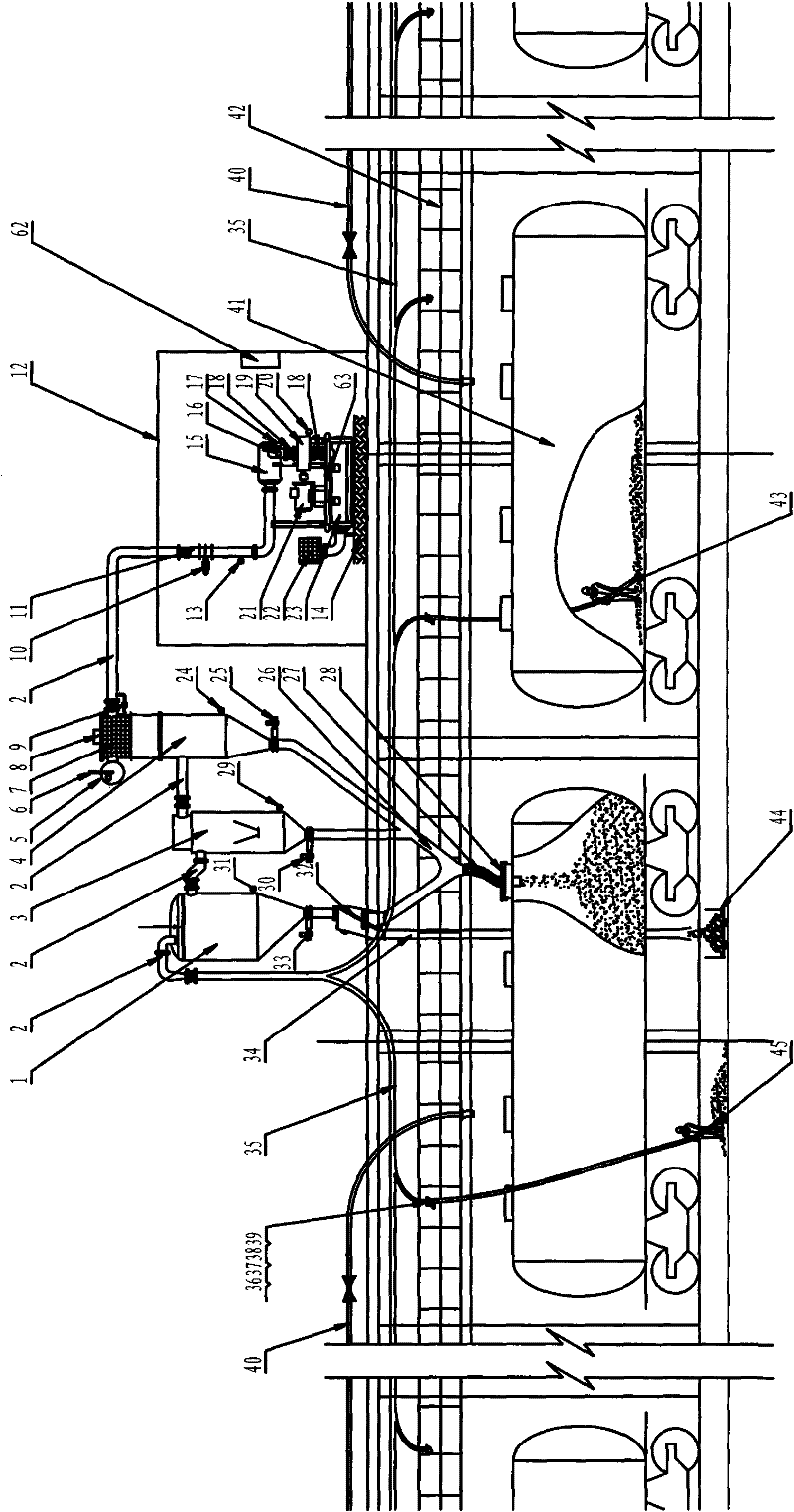

ActiveCN102268696AShort processEnable in-place recyclingCombination devicesWear resistantThree stage

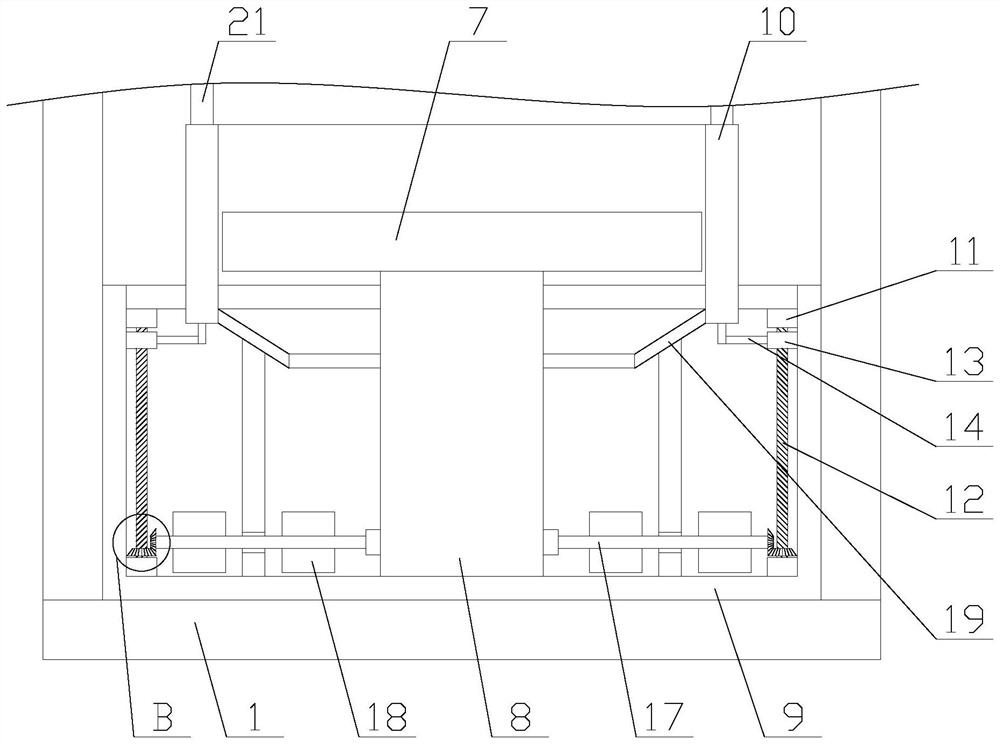

The invention relates to a method and an apparatus for recovery of remaining alumina and dust collection in alumina discharge stations. According to the invention, a negative pressure dust collection system and a fixed type design are employed; main equipment is installed in a central material knockout platform of a discharge station; power for negative pressure is generated by a Roots pump; a gathered material obtained through a material gathering nozzle is conveyed by a wear resistant flexible pipe and a wear resistant pipe network and subjected to three-stage separation of interception by a material storing bunker, separation by a cyclone dust collector and separation by a bag filler; recovered alumina is screened by a flap sieve and returned to a railway alumina tank car which is empty or half-empty after material knockout; and an alumina discharge station dilute phase system is used to convey the recovered alumina to an alumina storing bunker. The advantages of the invention are as follows: the problems of multi-time turning of vehicles, multi-time rising of alumina and incapability of removing impurities in stained alumina on the floor existing in manual digging and manual sweeping of alumina are overcome; valuable resources are recovered; waste is reduced; labor intensity of workers are mitigated; working environment is improved; working efficiency is enhanced; clean production is realized. Therefore, the apparatus provided is applicable to electrolytic aluminum factories, alumina factories, alumina loading and unloading stations and harbors.

Owner:傅文渊

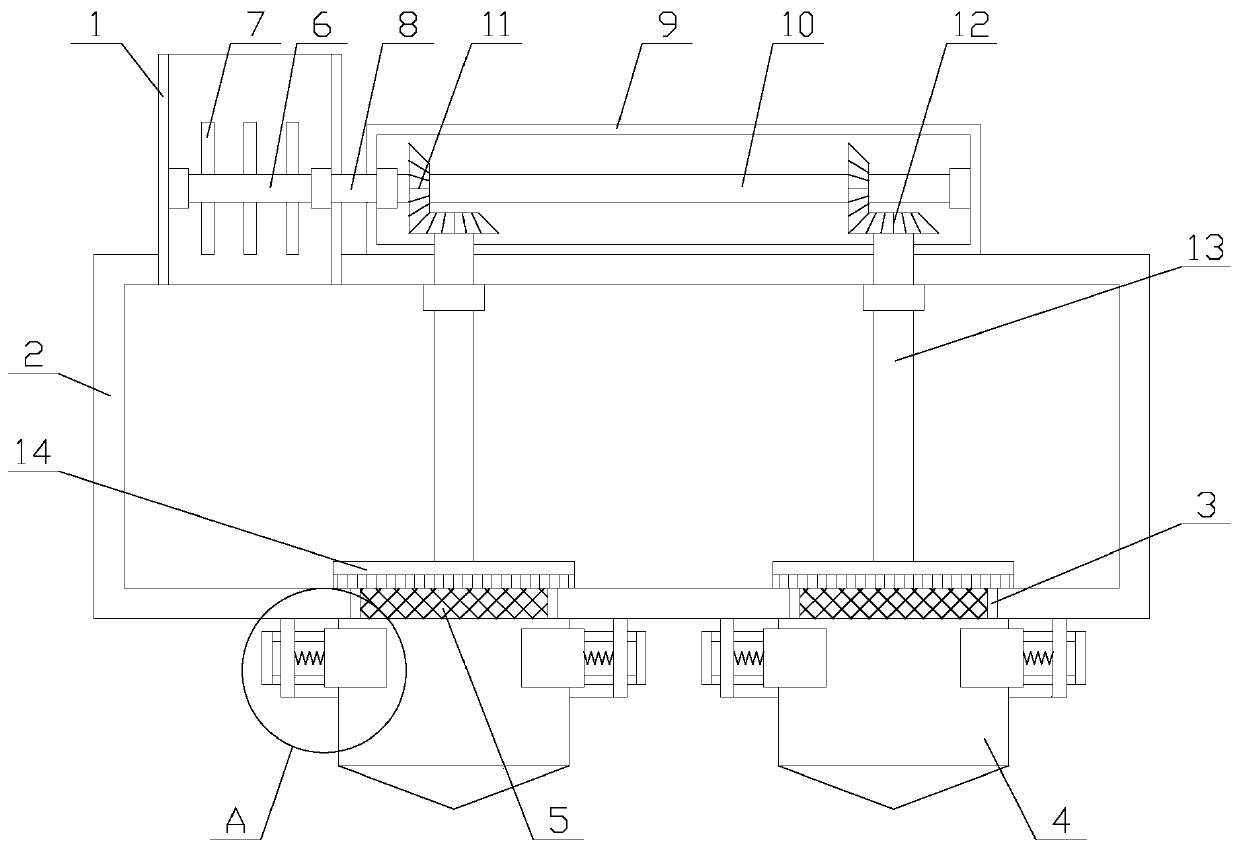

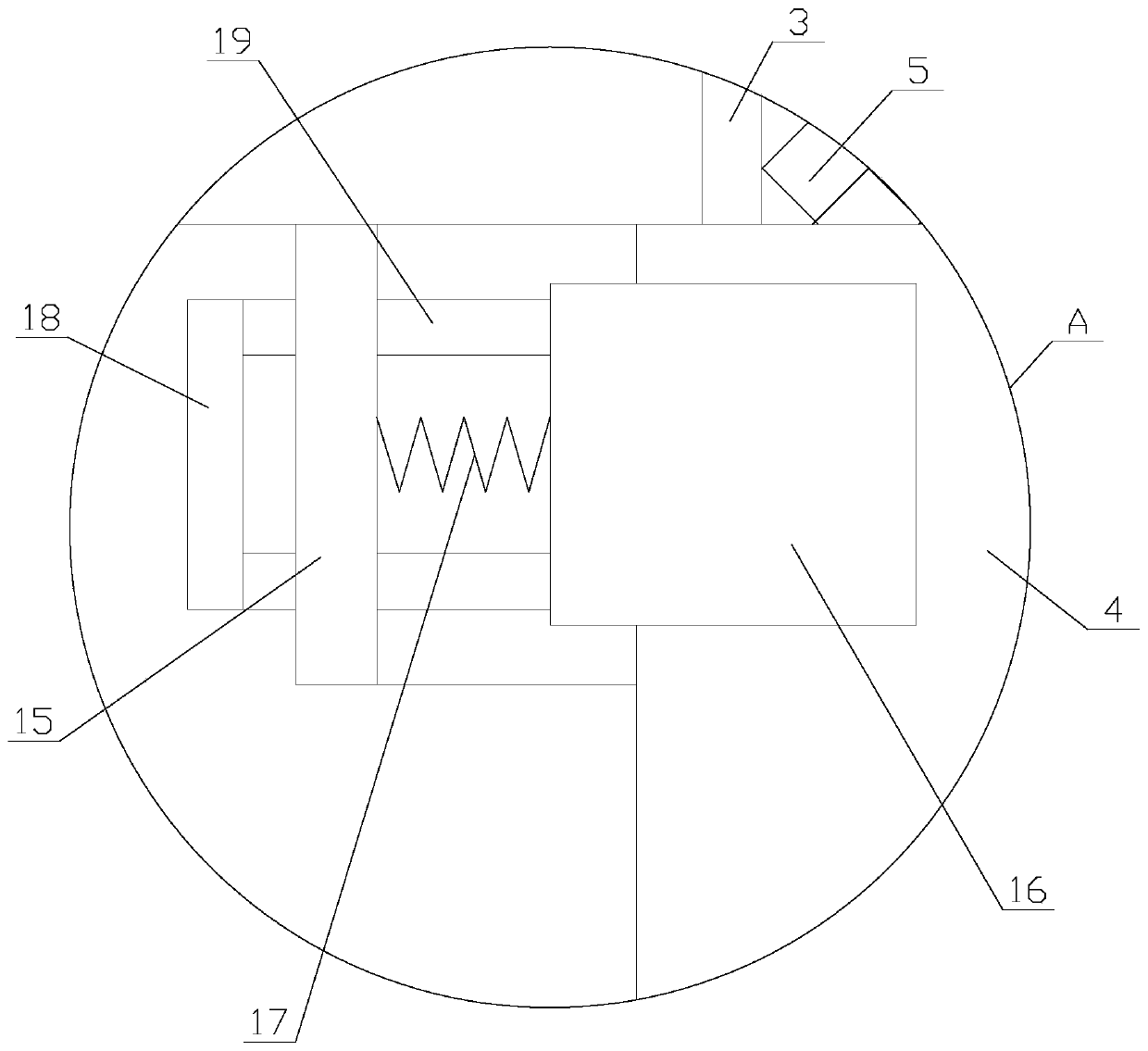

Convenient drip irrigation equipment with anti-blockage function

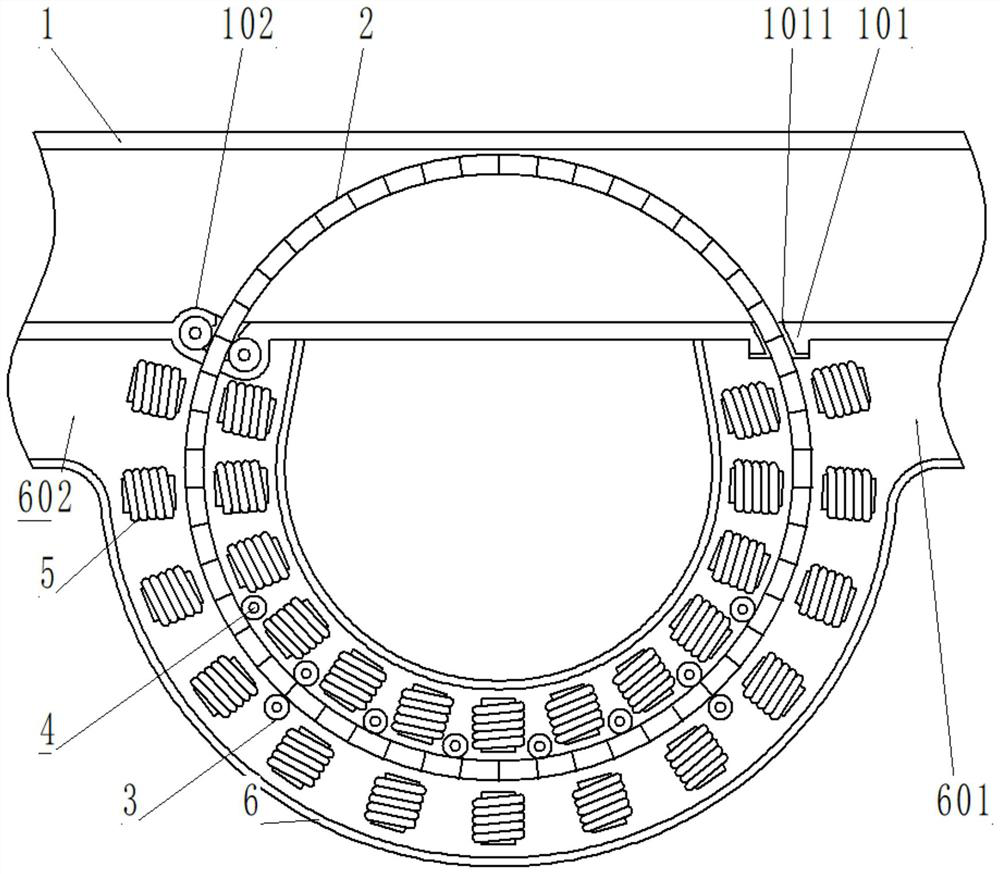

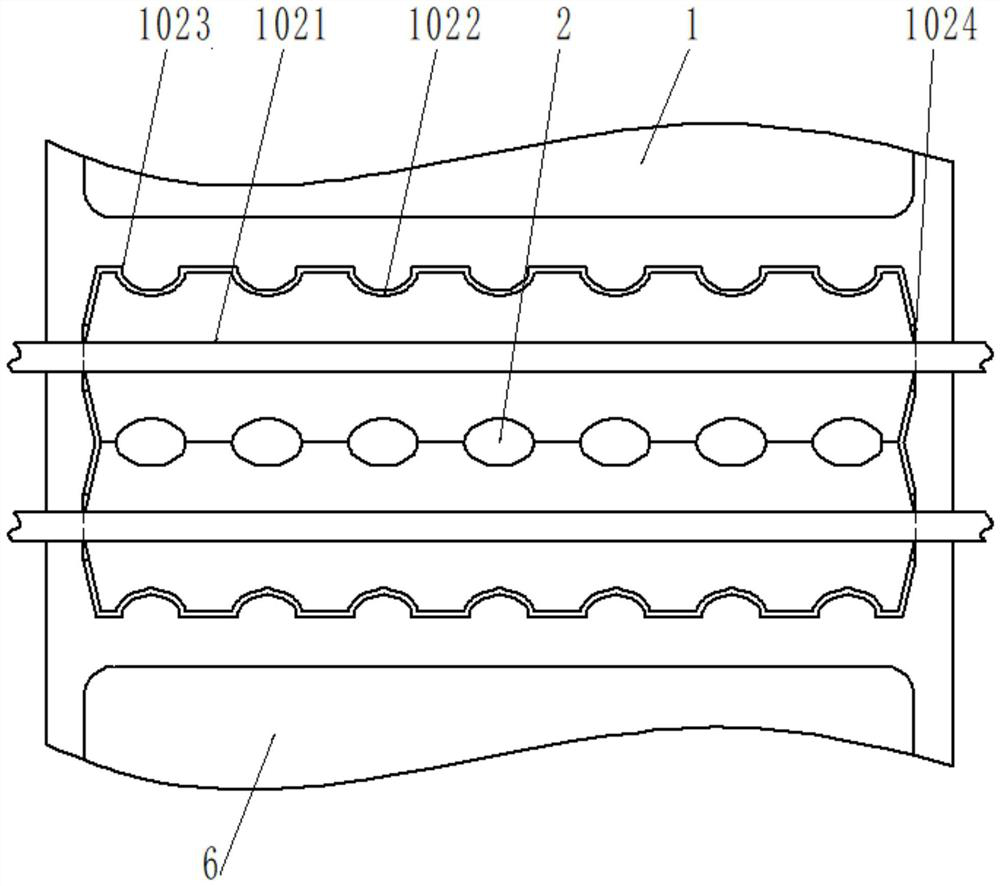

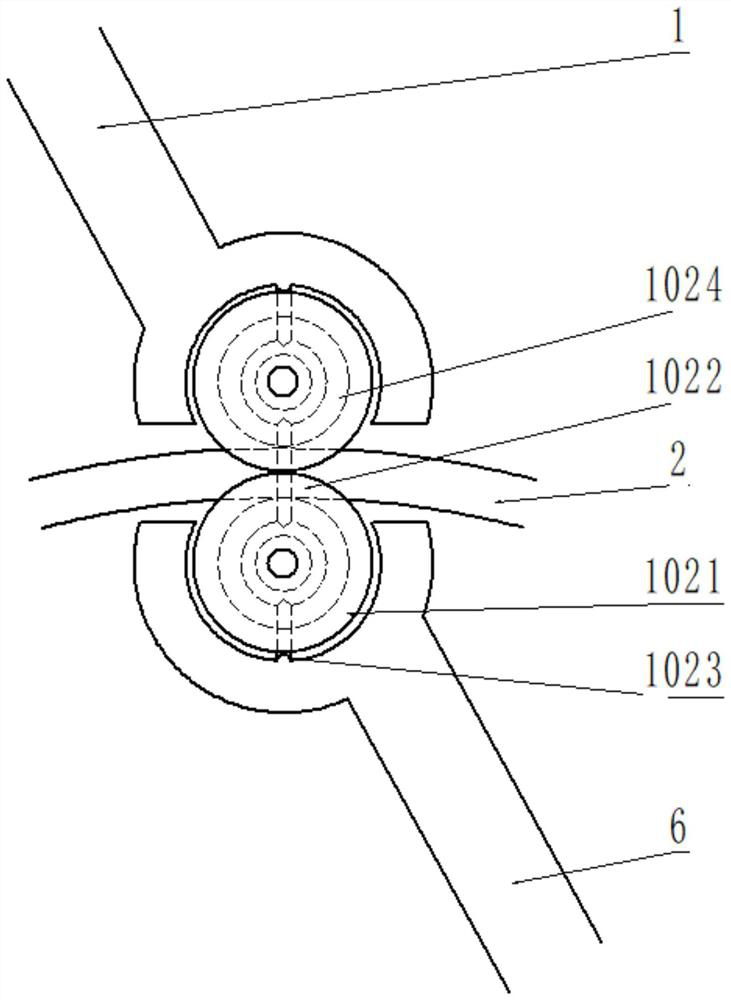

InactiveCN110521552AEasy to operateReduce cloggingClimate change adaptationWatering devicesDrip irrigationEngineering

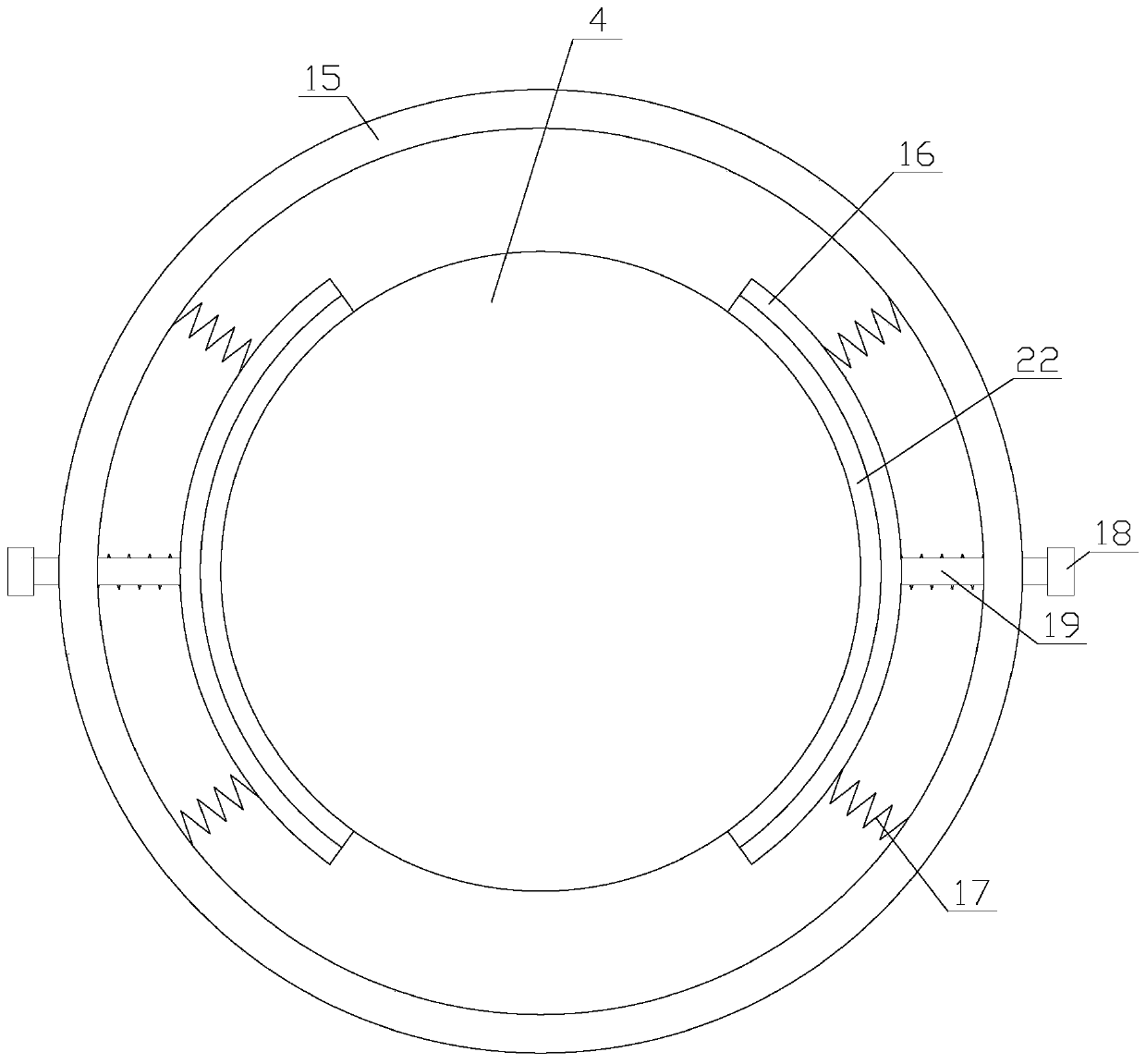

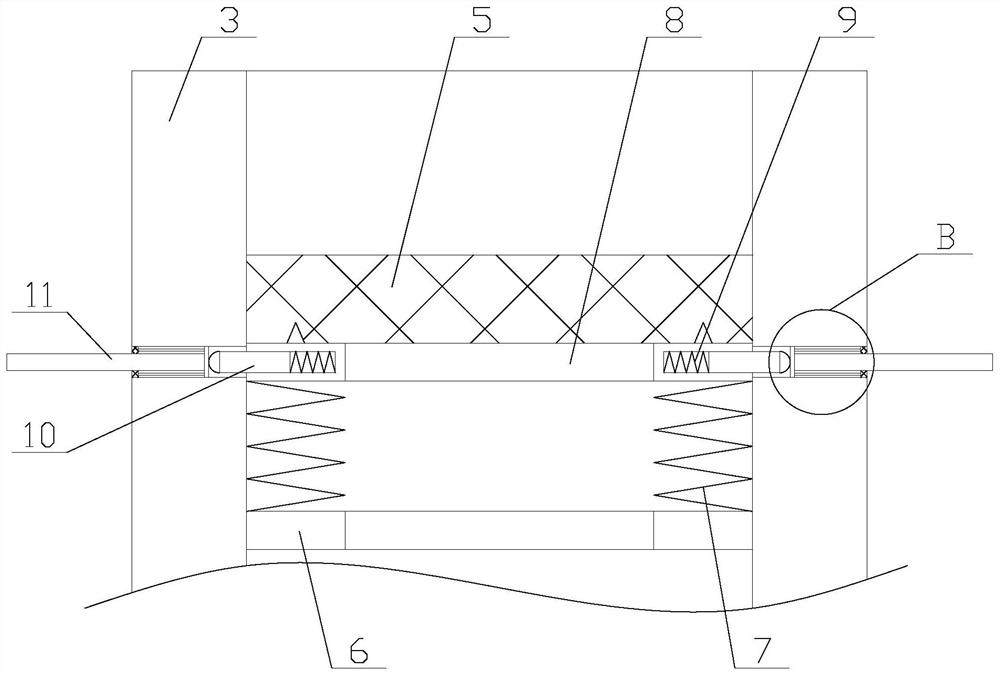

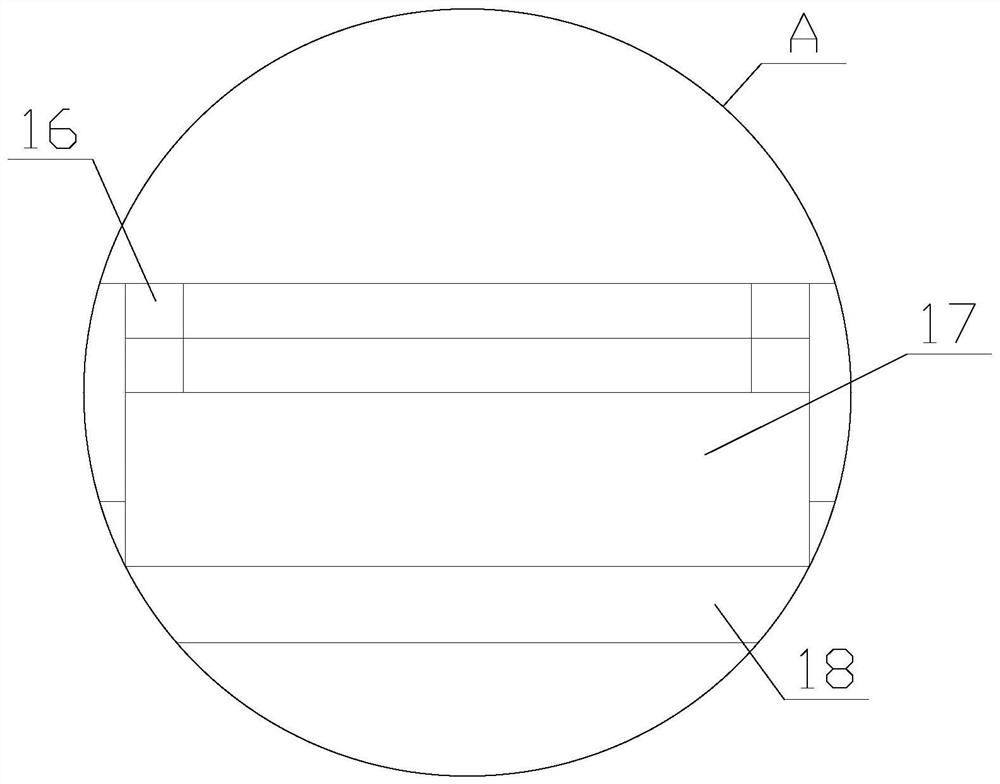

The invention relates to convenient drip irrigation equipment with an anti-blockage function. The equipment comprises a water inlet pipe, a drip irrigation belt, several drip irrigation devices, an anti-blockage mechanism and several installation mechanisms, the anti-blockage mechanism comprises a driving assembly, a fixed rod, a fixed box, a transmission shaft, two first bearings, several filtering screens and several cleaning assemblies, each installation mechanism comprises a fixed ring and two installation assemblies, and each installation assembly comprises an installation plate, a movingunit and several springs. The convenient drip irrigation equipment with the anti-blockage function achieves an impurity removal function through the anti-blockage mechanism and reduces the probability of blockage of drip irrigation heads, the practicability of the equipment is improved, and through the installation mechanisms, convenience of disassembly and assembly of the drip irrigation heads is improved.

Owner:SHENZHEN JIUPIN AIR PURIFICATION TECH CO LTD

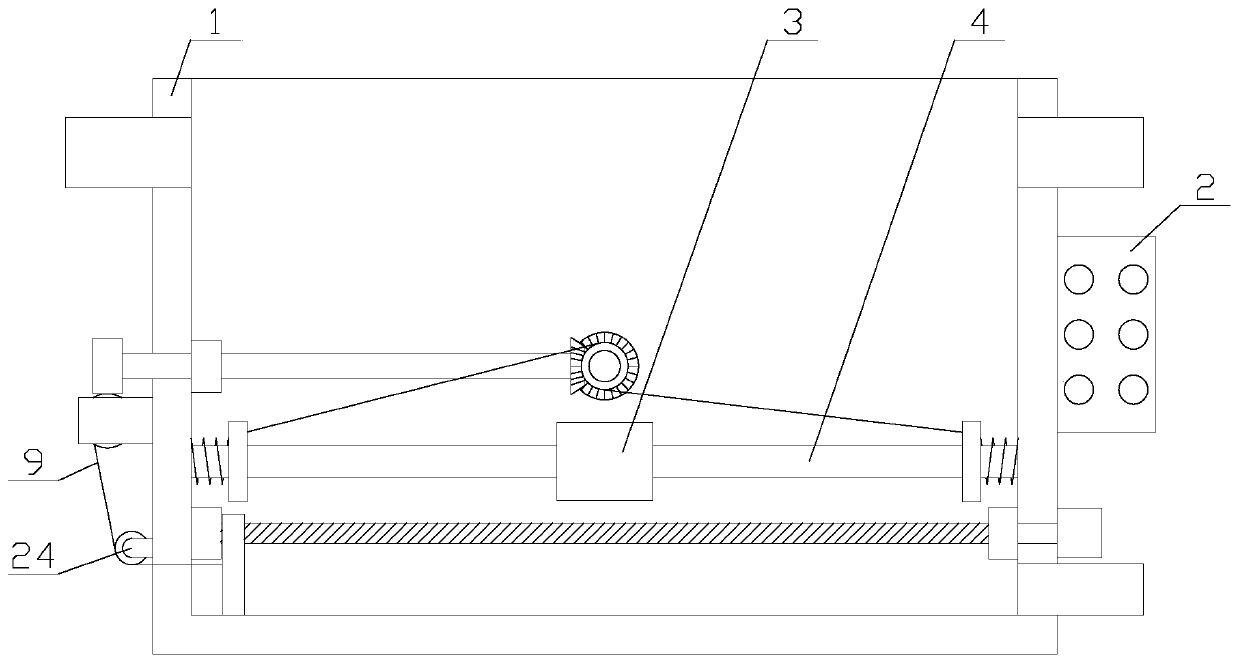

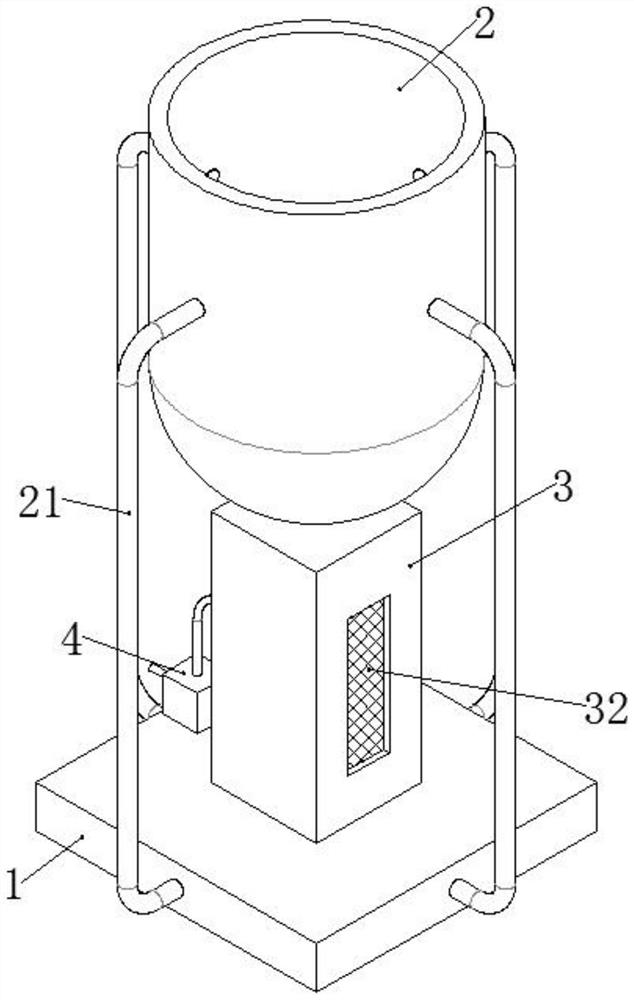

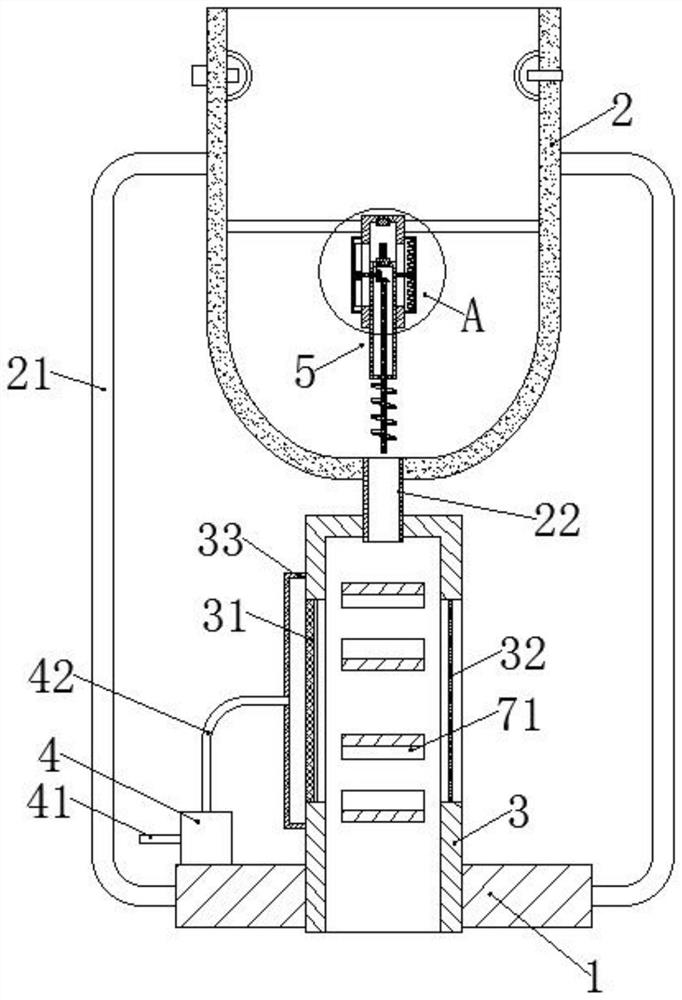

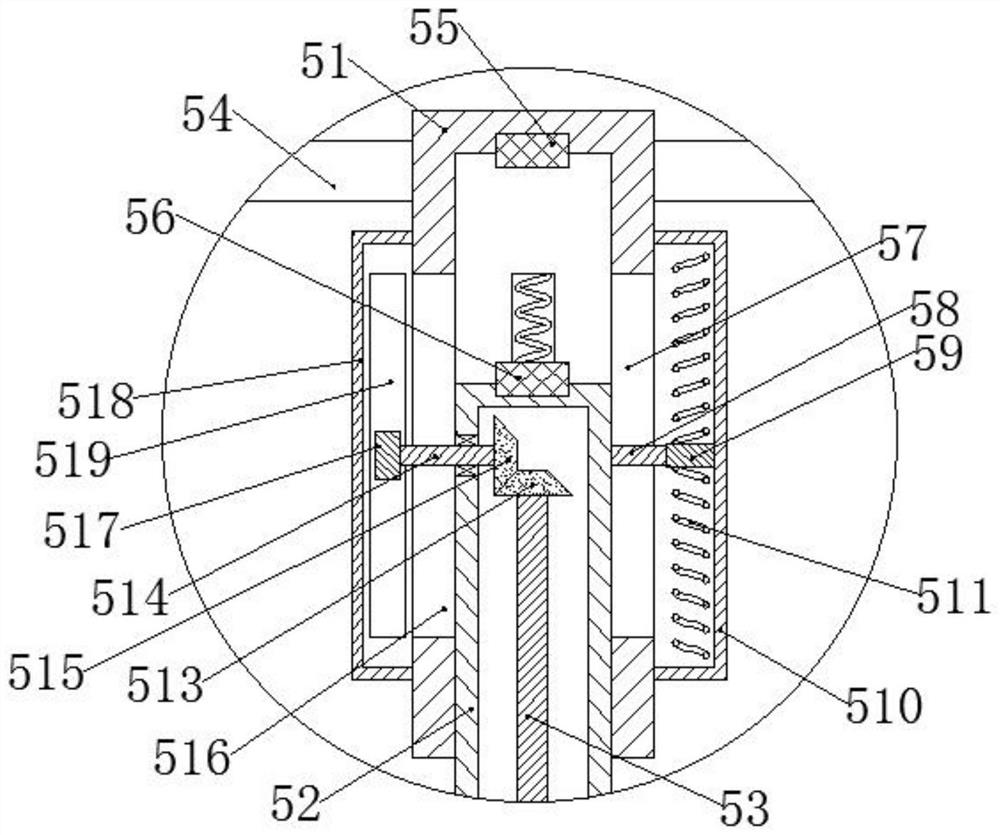

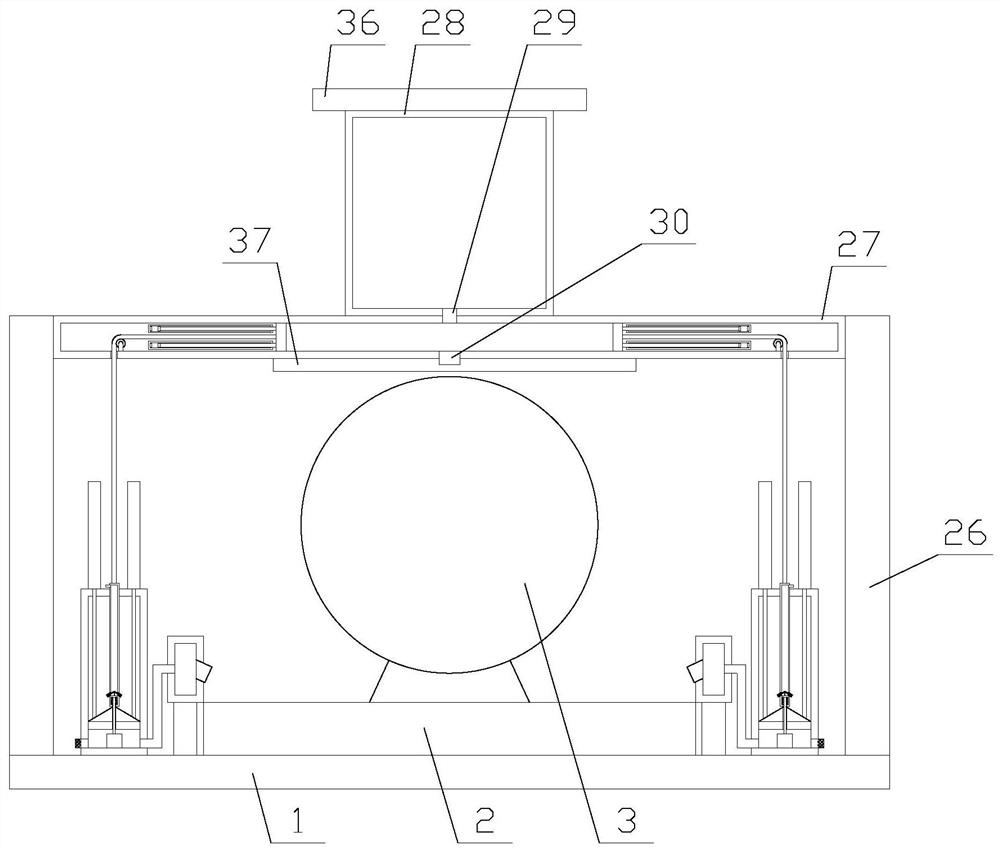

Air floatation equipment with anti-blocking function for sewage treatment

InactiveCN110668523AImplement the cleanup functionRealize the function of removing impuritiesSpecific water treatment objectivesWater/sewage treatment by flotationSludgeElectric machinery

The invention relates to an air flotation device with an anti-blocking function for sewage treatment, which comprises a main body, a water inlet, a water outlet, a slag outlet, an aerator, a control board, two aeration pipes, a cleaning mechanism and an impurity removal mechanism, wherein the cleaning mechanism comprises a motor, a screw rod, a scraper and two first bearings; the impurity removalmechanism comprises a connecting component, a transmission component, a turntable and two impurity removal components; and the impurity removal component comprises a cleaning ring, a first spring anda pull wire. The air flotation device with anti-blocking function for sewage treatment realizes the function of cleaning sludge at the bottom of the main body through the cleaning mechanism, and improves the cleaning convenience; and through the impurity removal mechanism, the impurity removal function of the aeration pipe is realized, so that dust is prevented from blocking the aeration hole andinfluencing the air circulation.

Owner:汪东梅

Electroplating equipment with impurity removal function

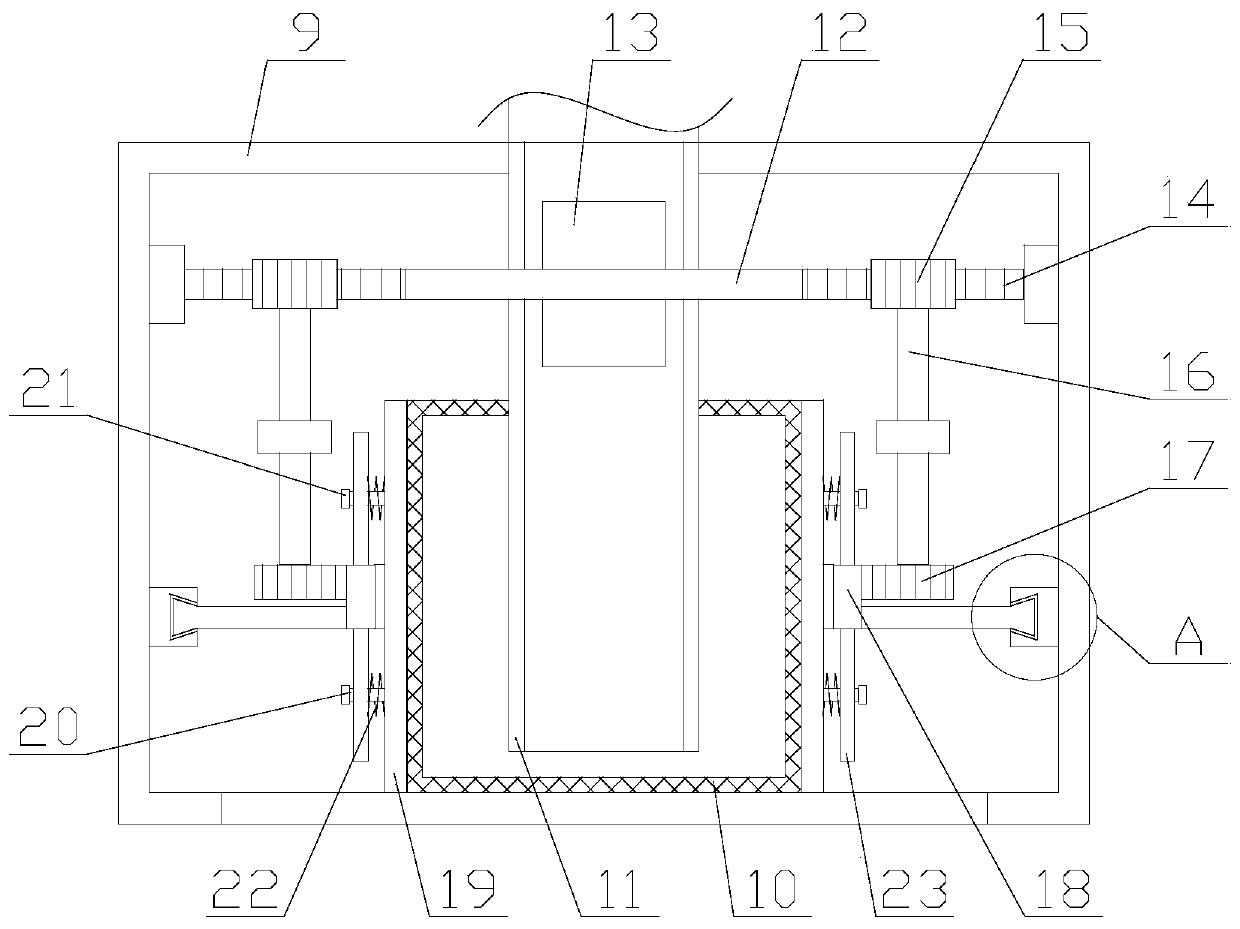

The invention relates to electroplating equipment with an impurity removal function. The electroplating equipment comprises a main body, a supporting plate, a lifting device, a lifting plate and two supporting columns, and further comprises a stirring mechanism and two impurity removal mechanisms; the stirring mechanism comprises a protection assembly and two stirring assemblies, and each stirringassembly comprises a first bearing, a rotating shaft, a paddle, a driving unit and a control unit; the protection assembly comprises a connecting ring, two protection units and two air cylinders; each impurity removal mechanism comprises an impurity removal box, a filter screen, a water pumping assembly, a circulating assembly and an impurity removal assembly; and each impurity removal assembly comprises an abutting plate, a second spring, a connecting rod and a scraper blade. According to the electroplating equipment with the impurity removal function, the stirring mechanism can be used forstirring liquid zinc inside the main body, and flow of the liquid zinc is accelerated, so that the galvanizing quality is guaranteed, meanwhile, the electroplating speed can be increased, the electroplating time is shortened, and the working efficiency is improved; and through the impurity removal mechanisms, the function of removing impurities from the liquid zinc is achieved, and reduction of the galvanizing quality due to the excessive impurity content in the liquid zinc is avoided.

Owner:广州市欧伊若科技有限公司

Paint spraying equipment with anti-splashing function

The invention relates to paint spraying equipment with an anti-splashing function. The paint spraying equipment comprises a bottom plate, a fixed box, a supporting column, a platform, a top plate, a material box, a connecting pipe, a paint spraying pipe and two supporting columns, and further comprises an anti-splashing mechanism and an impurity removing mechanism; and the anti-splashing mechanismcomprises a lifting plate, two moving assemblies, two stirring assemblies and four scraping assemblies, each moving assembly comprises a motor, a lead screw, a sliding block, a supporting rod and a first bearing, each stirring assembly comprises a second bearing, a rotating shaft, a transmission unit and two stirring units, and each scraping assembly comprises a scraping plate and a fixing rod; and the impurity removing mechanism comprises an impurity removing net, a smashing plate, a third bearing, a connecting shaft, a connecting disc, a torsion spring, a support and two connecting ropes. According to the paint spraying equipment with the anti-splashing function, the shielding function is achieved through the anti-splashing mechanism, it is avoided that paint splashes to the body of a worker to affect the cleanliness of the worker, the impurity removing function is achieved through the impurity removing mechanism, and it is avoided that the quality of a finished product is affecteddue to the fact that the paint contains too much impurities.

Owner:南京欧伊工程技术有限公司

Agricultural production irrigation device with filter function

InactiveCN111357620AImprove practicalityPrevent being drawn inWatering devicesCultivating equipmentsEnvironmental engineeringMechanical engineering

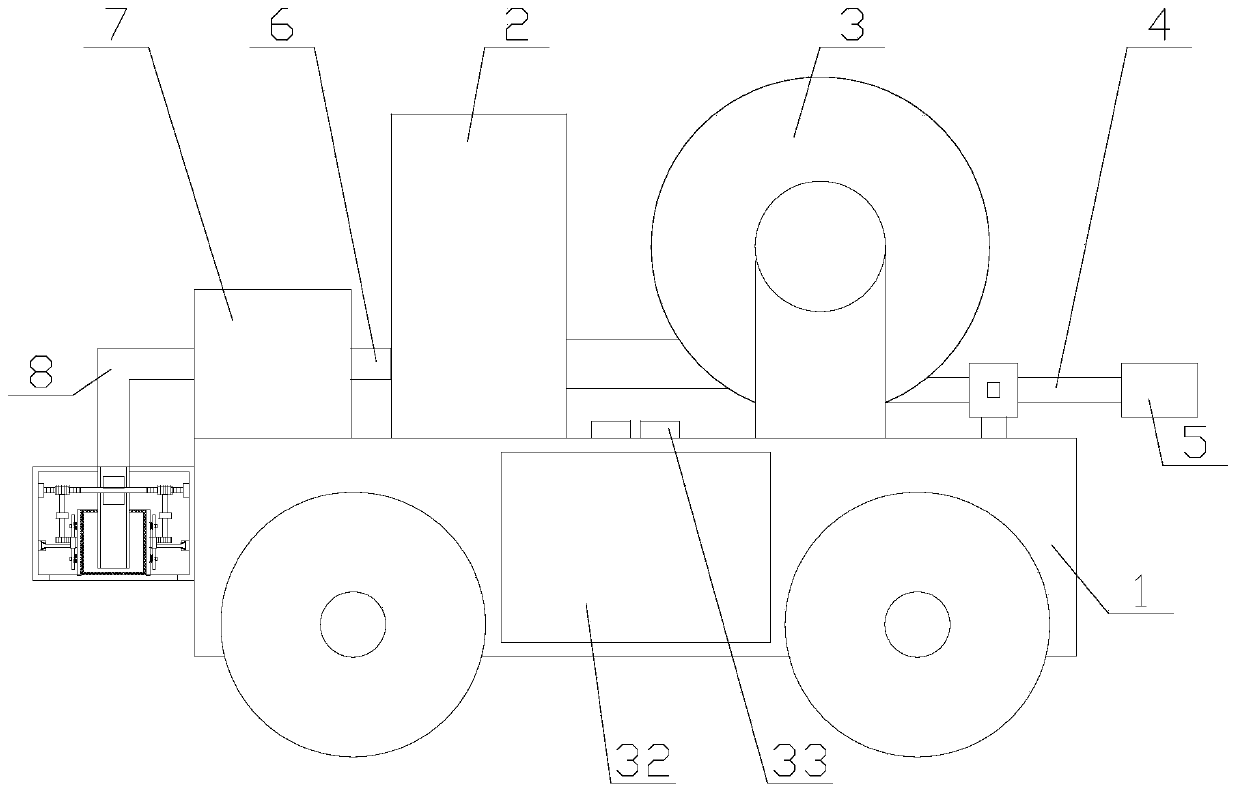

The invention relates to an agricultural production irrigation device with a filter function. The agricultural production irrigation device with a filter function includes a vehicle body, a water pump, a water tank, a winding device, a water pipe, a nozzle, a hose, a water outlet pipe, a filter mechanism and a water drainage mechanism, wherein the water drainage mechanism includes a connection ring, fixing blocks and two water drainage components, each water drainage component includes a pressure plate, a pressure rod, a squeeze plate and a spring, the filter mechanism includes a fixed box, awater pipe, a filter cartridge, a circular ring, a limiting component, a drive component, two transmission assemblies and two cleaning assemblies, and each cleaning assembly includes a scraper blade and two connection units. According to the agricultural production irrigation device with a filter function, the function of impurity removal can be achieved through the filter mechanism, aquatic organisms can be prevented from being pumped into the water tank, and the chance of nozzle clogging is reduced; the squeezing function is achieved through a squeezing mechanism, water left in the water pipe is squeezed out conveniently, the weight of the water pipe is reduced, and the water pipe is winded conveniently, so that the convenience of water pipe winding is improved.

Owner:南京绿源达农业设备有限公司

Environment-friendly watering cart

InactiveCN113026644AAvoid wastingPromote environmental protectionGeneral water supply conservationRoad cleaningCartElectric machinery

The invention relates to an environment-friendly watering cart which comprises a main body, a water tank, a watering device and two moving devices and further comprises a rainwater collecting mechanism and an impurity removing mechanism, and the rainwater collecting mechanism comprises a rainwater collecting cover, a communicating pipe, a valve, a control assembly and two fixing rods; and the impurity removing mechanism comprises a filter screen, a scraping plate, a connecting assembly, a motor, a rotating shaft, a rotating disc, a pull rope, two collecting assemblies, two guide blocks and a plurality of elastic ropes. According to the environment-friendly watering cart, the rainwater collecting function is achieved through the rainwater collecting mechanism, watering work is conducted through rainwater, and therefore waste of water resources is avoided, and the environmental protection property of the equipment is improved; and through the impurity removing mechanism, the function of removing impurities from water in the water tank is achieved, the situation that the watering device is damaged due to excessive impurities is avoided, the influence on normal watering of the watering device is avoided, and therefore the reliability of the equipment is improved.

Owner:吴小香

Feeding equipment with impurity removal and anti-blocking functions for feed production

PendingCN113526167AFalling smoothlyAvoid cloggingGas current separationFeeding-stuffProcess engineeringFodder

The invention discloses feeding equipment with impurity removal and anti-blocking functions for feed production. The feeding equipment comprises a base, a hopper, an impurity removal bin, an impurity removal fan and an anti-blocking device, wherein the anti-blocking device comprises a fixed cylinder, a lifting cylinder and an anti-blocking rod. Feed particles enter the hopper and enter the impurity removal bin through a feeding pipe, in the feeding process, through the arrangement of the anti-blocking device, the phenomenon that the feeding pipe is blocked can be avoided, feeding is smoother, in the falling process of feeds in the impurity removal bin, the impurity removal fan extracts external air through an air inlet pipe and conveys the air into a fan cover through an air outlet pipe, then the air is blown into the impurity removal bin through a first filter screen, chippings can be blown out through a second filter screen, and therefore the impurity removal function is achieved; and the second filter screen can also intercept the feed particles in the impurity removal bin, so that the feed particles can smoothly fall down from the bottom of the impurity removal bin.

Owner:武汉市新洲区万鹏饲料厂

Spray tower with adjusting function for waste gas treatment

InactiveCN111359378AEasy to handleReduce cloggingDispersed particle separationStationary filtering element filtersCircular discEnvironmental engineering

The invention relates to a spray tower with an adjusting function for waste gas treatment. The spray tower comprises a main body, a spraying pipe, an air inlet pipe, an air outlet pipe, a sucking pump, a feeding pipe and a discharging pipe. The spray tower also comprises an adjusting mechanism and an impurity removing mechanism. The adjusting mechanism comprises a ventilation plate, a transmissionassembly, two connecting assemblies, two limiting assemblies and two baffles. The impurity removing mechanism comprises a filter screen and a cleaning assembly. The cleaning assembly comprises a first bearing, a rotating shaft, a disc, a connecting wire, a torsion spring and a plurality of scraping plates. The impurity removal function is achieved through the filtering mechanism, the nozzle blockage probability is reduced, the practicability of the spray tower is improved, the inlet amount of waste gas can be adjusted through the adjusting mechanism, the waste gas can make full contact with absorption liquid, and the waste gas treatment effect is improved.

Owner:王树东

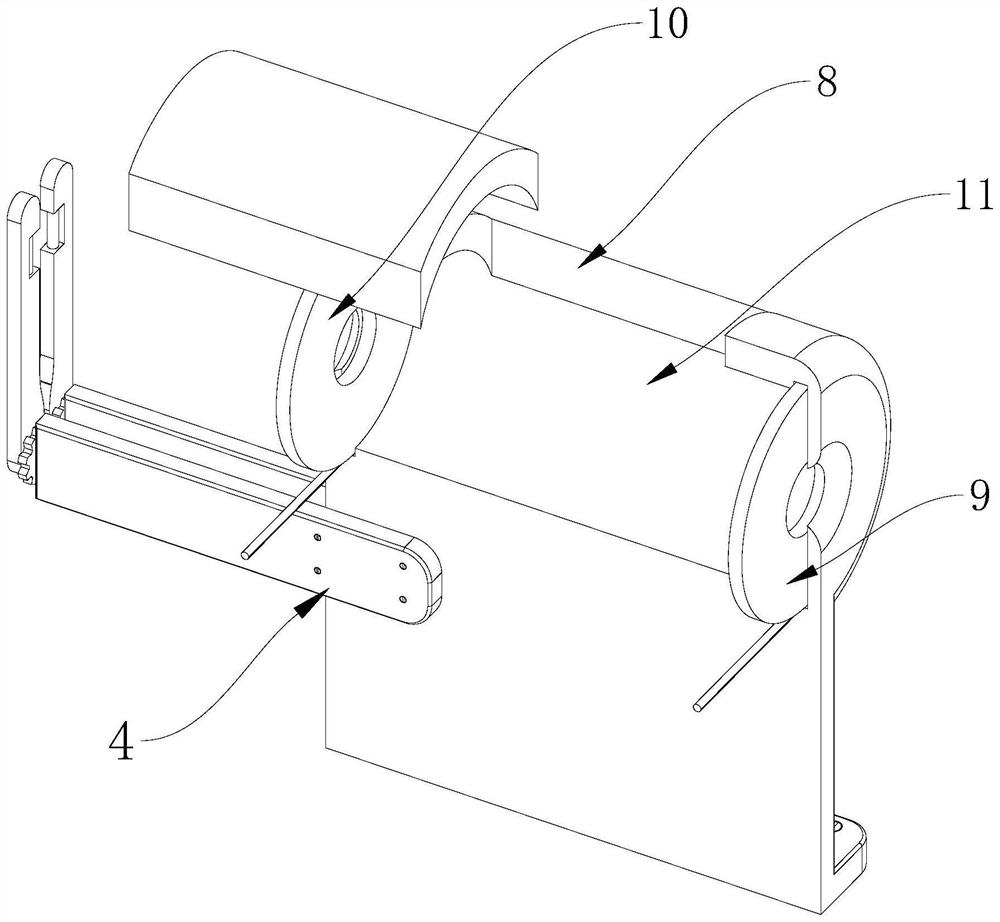

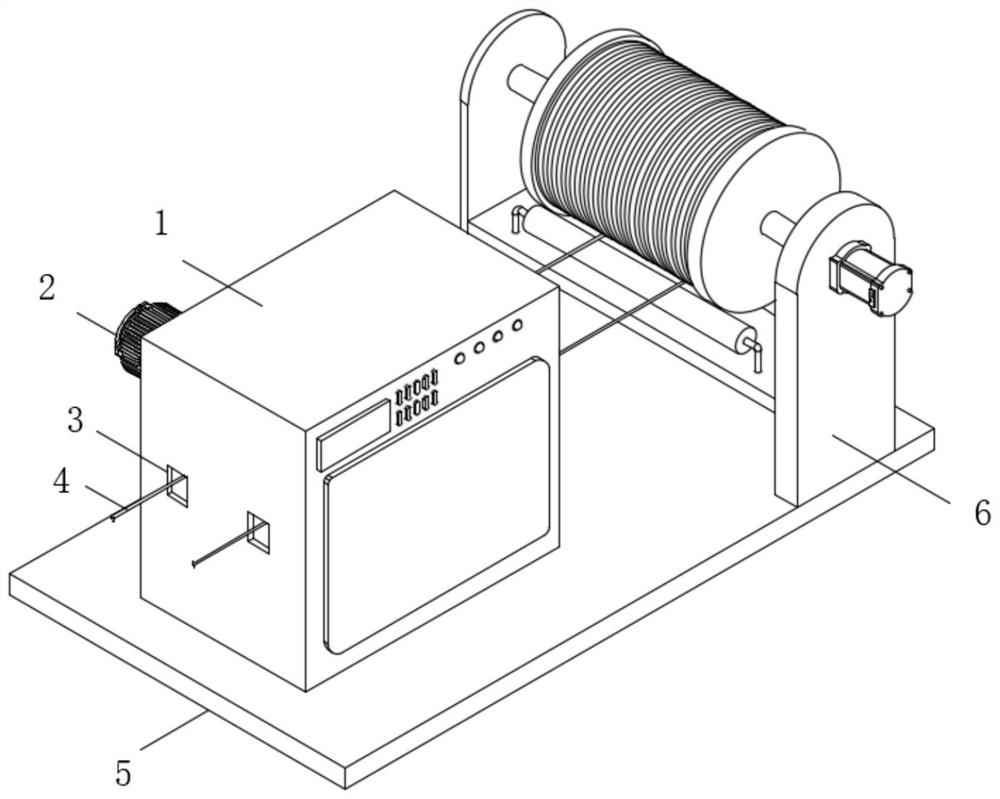

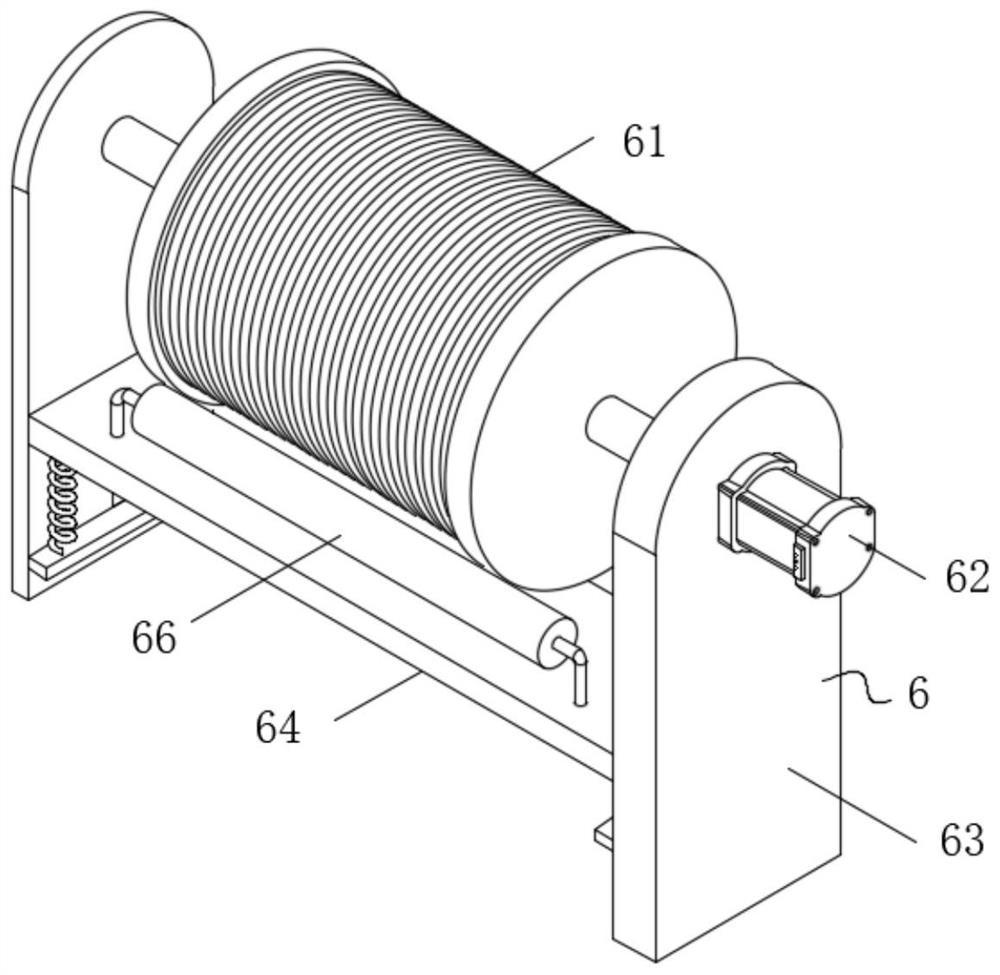

Winding machine with high reliability

InactiveCN112173855AReduce the chance of separationPrevent the influence of winding workFilament handlingWinding machineYarn

The invention relates to a winding machine with high reliability. The winding machine with high reliability comprises a main body, a bottom plate, a stabilizing mechanism, a dedusting mechanism, a winding, a yarn, a spool, a fixed pipe, a rotating plate, a rotating shaft, a first bearing and a driving device. The stabilizing mechanism comprises a pressure bar, a pressing plate, a first spring, a transmission assembly, a connecting shaft, a fixed bar, two second bearings, two fixing assemblies, two limiting assemblies and two power assemblies. Each power assembly comprises a first lead screw, aball lead screw bearing, a supporting rod and two third bearings. Each fixing assembly comprises a second lead screw and a bushing. The dedusting mechanism comprises a lantern ring, an air extractionassembly, a fixed box, two supporting rods and a plurality of nozzles. The winding machine with high reliability has a function of fixing the spool by means of the stabilizing mechanism, so that thespool does not move up and down during work, and therefore, the probability that the spool and the fixed pipe are separated is reduced and thus, a condition that winding work is affected is prevented.By means of the dedusting mechanism, the winding machine has a function of removing impurities for the yarn, so that the yarn quality is improved.

Owner:程国花

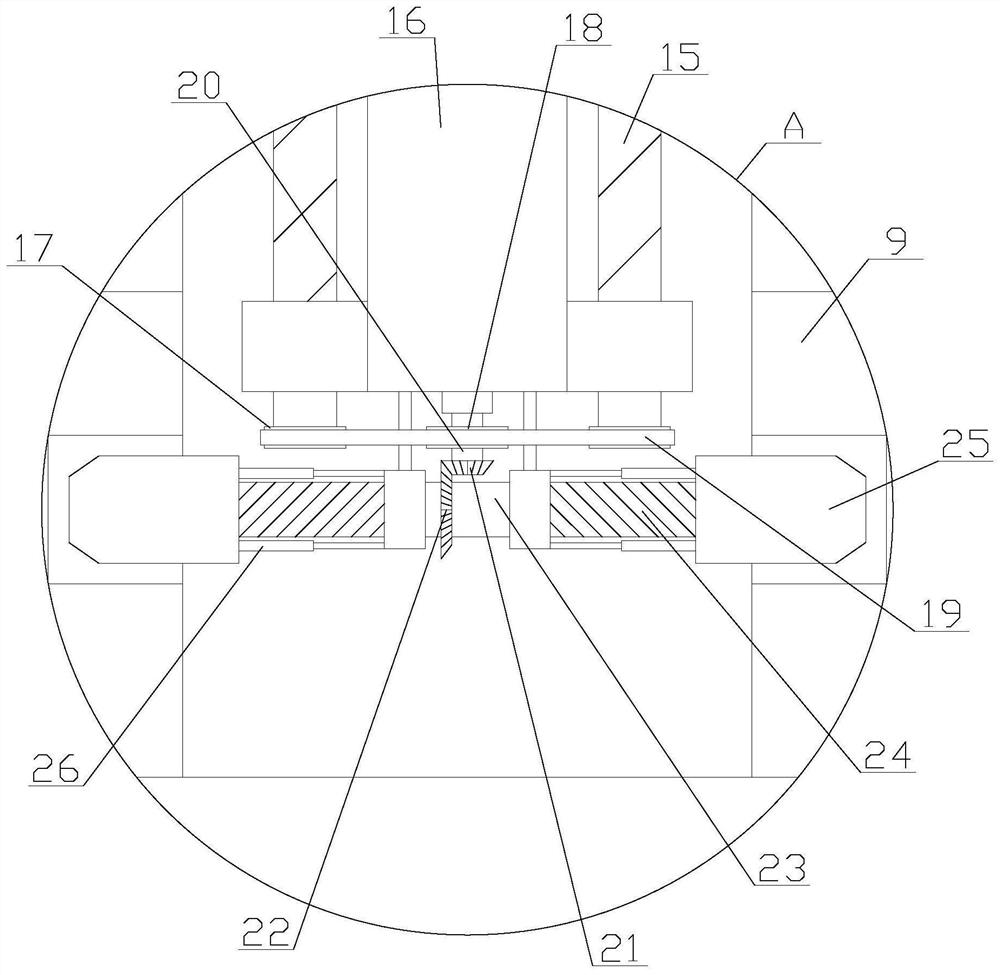

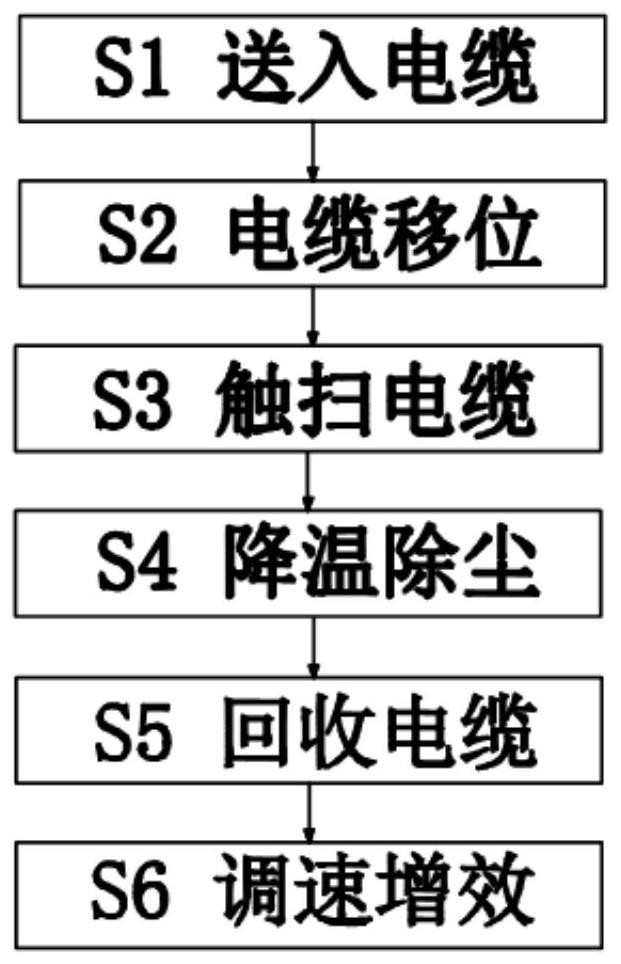

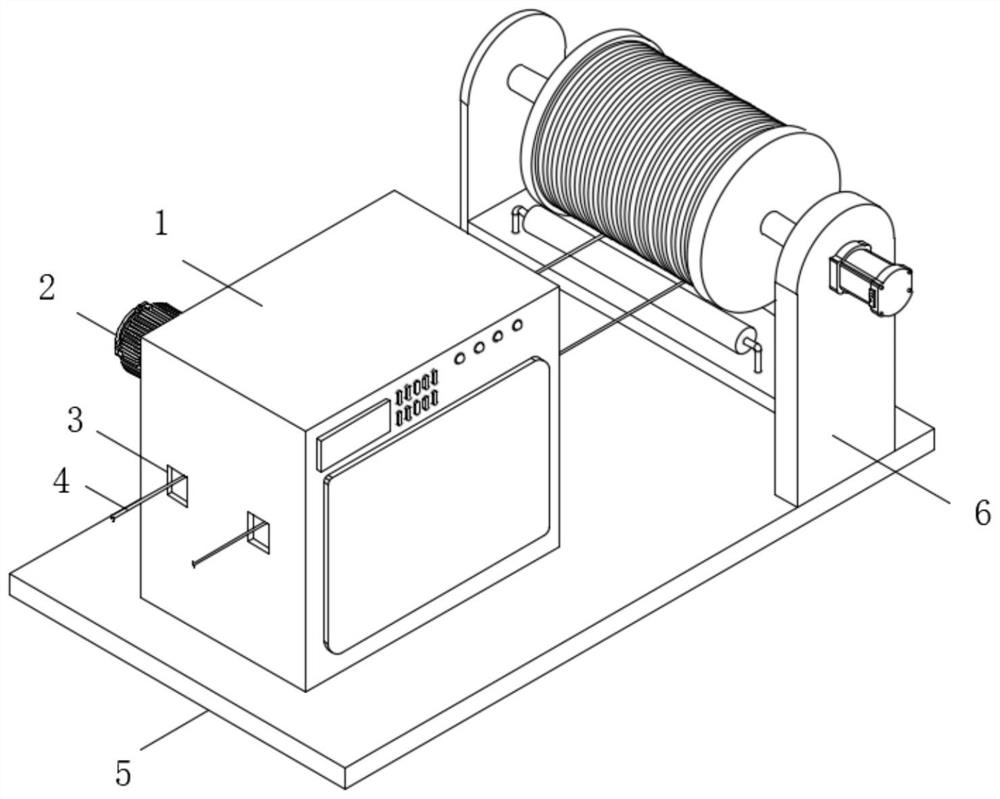

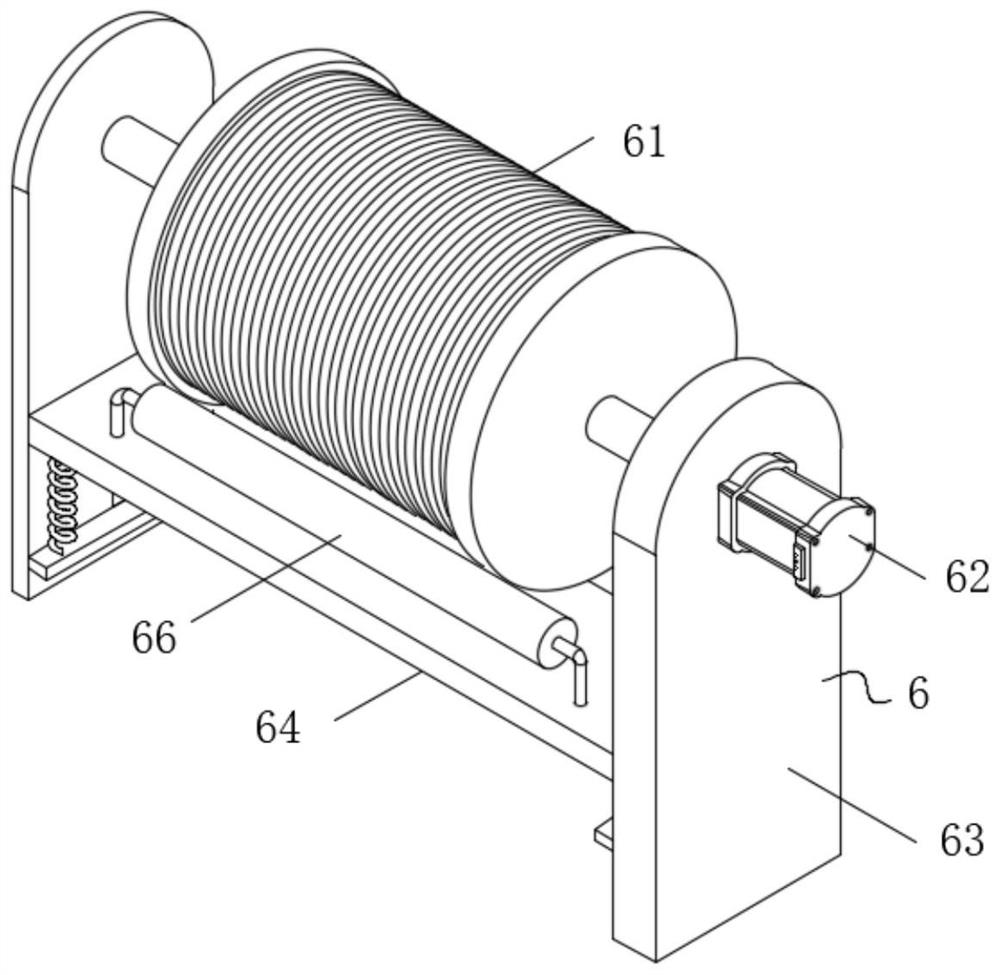

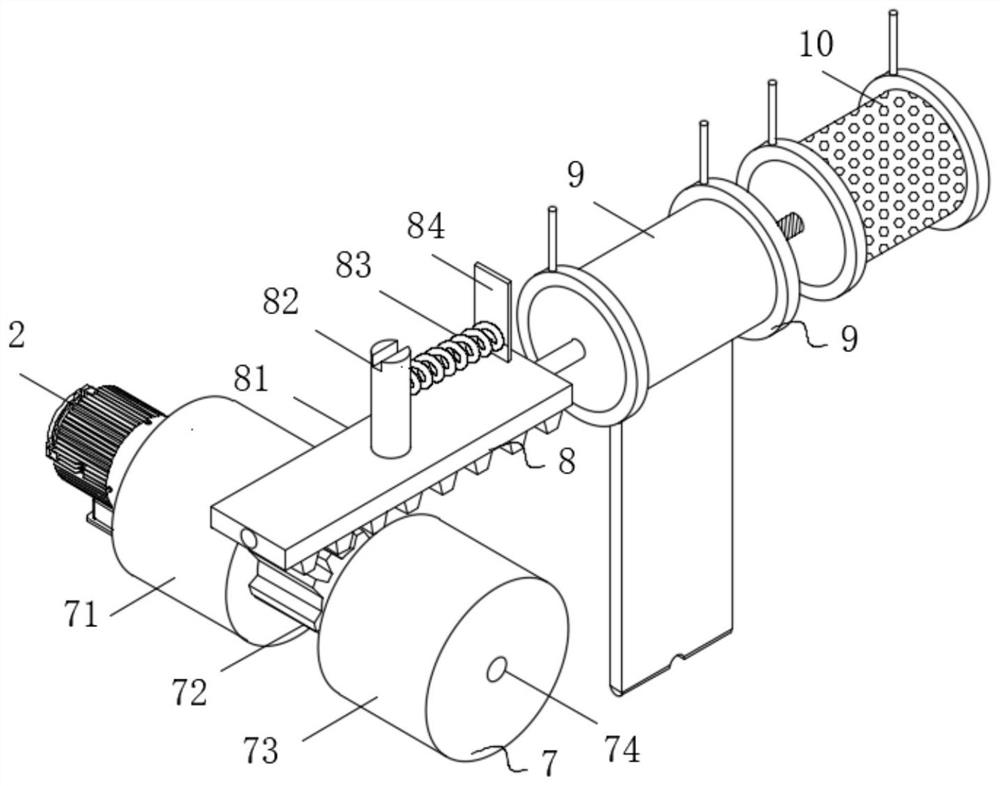

High-voltage cable checking method

PendingCN114660173ARealize reciprocating motionRealize the function of removing impuritiesAnalysing solids using sonic/ultrasonic/infrasonic wavesCleaning using gasesElectric machineryStructural engineering

The invention discloses a high-voltage cable checking method which adopts a high-voltage cable checking instrument, the high-voltage cable checking instrument comprises a base, an ultrasonic checking machine and a take-up mechanism are fixedly mounted at the top of the base, and a cable conduction platform is arranged in the ultrasonic checking machine. Two inlet grooves are formed in the side wall of the ultrasonic troubleshooting machine, detection cables are arranged in the two inlet grooves, a driving motor is fixedly installed on the side wall of the ultrasonic troubleshooting machine, and a conduction assembly is fixedly installed at one end of an output shaft of the driving motor and used for detecting stable conduction of the cables; a magnetic brushing assembly and a turbulent flow assembly are arranged on the inner wall of the top surface of the ultrasonic checking machine; according to the invention, through the arrangement of the driving assembly and the magnetic brushing assembly, and through the design of the linkage assembly, the magnetic impurity removal function in the cable conduction process is realized, so that the precision of a subsequent troubleshooting result is stably improved, and adverse effects on troubleshooting are avoided.

Owner:李勇为

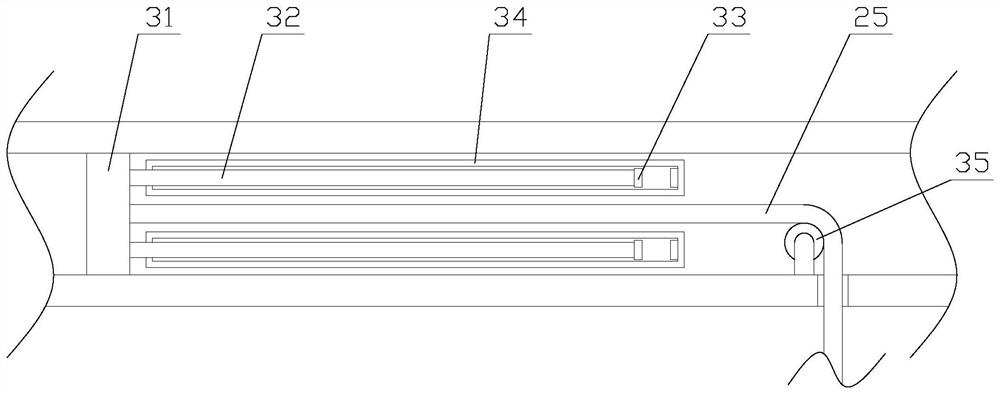

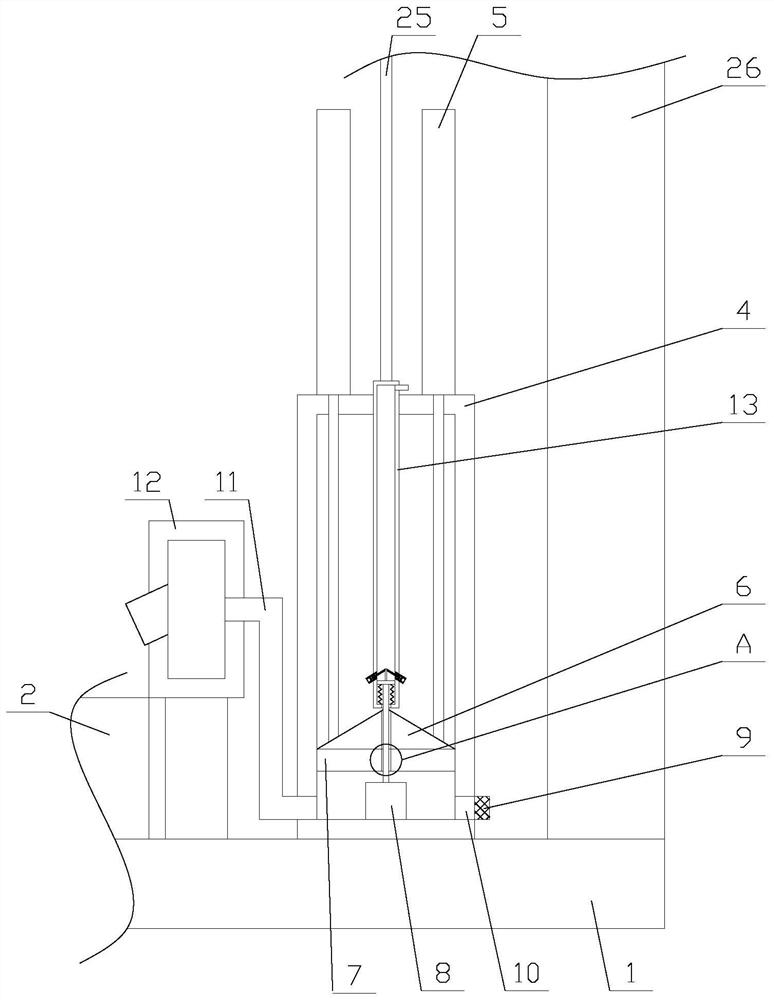

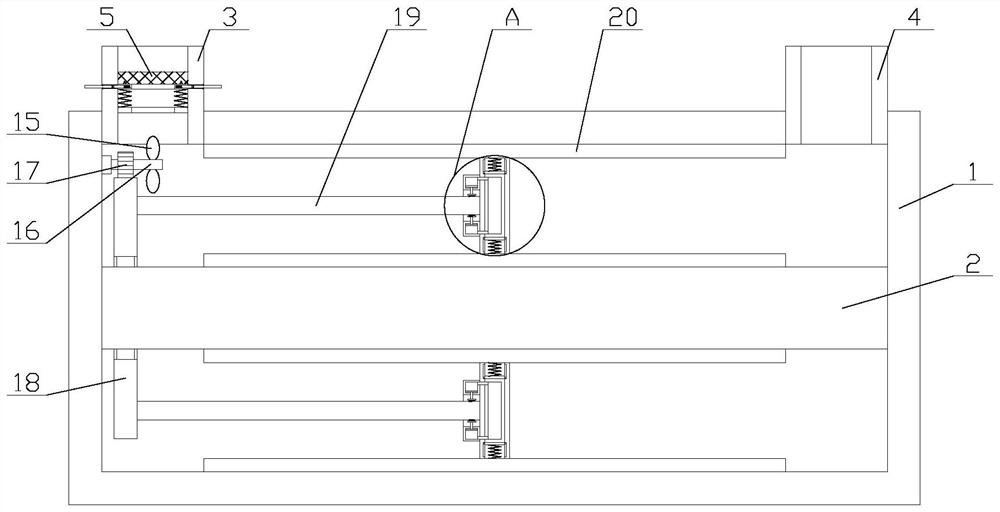

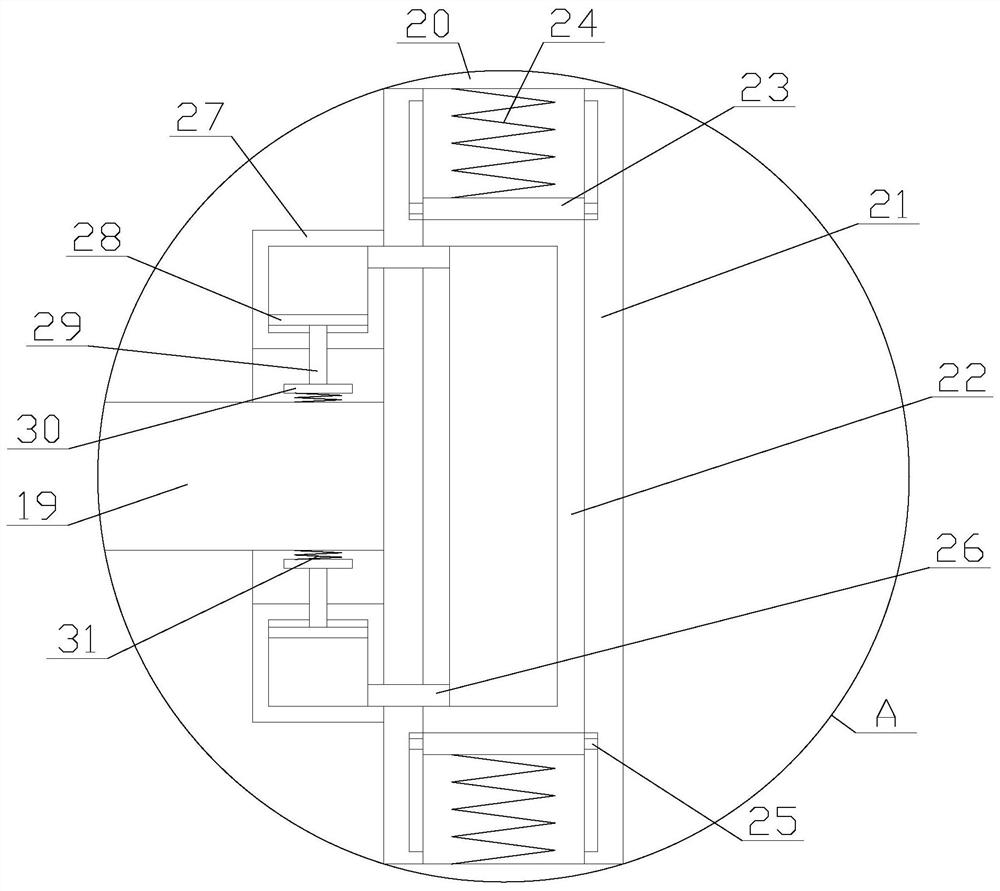

A safe and reliable new energy vehicle charging pile with good waterproof effect

ActiveCN108583319BImprove waterproof performanceIngenious structureCharging stationsElectric vehicle charging technologyNew energyProtection mechanism

The invention relates to a safe and reliable new energy vehicle charging pile with a good waterproof effect. The safe and reliable new energy vehicle charging pile with the good waterproof effect comprises a main body, a sun visor, a hook, a display screen, a lead and a charging gun; a concave opening is formed in the main body; the charging gun is arranged in the concave opening; the bottom of the sun visor is fixedly connected with the top end of the main body; the hook is fixed on one side of the main body; the charging gun is connected with the main body through a lead; the lead is arranged on the hook; the display screen is arranged on the main body; a waterproof mechanism and a protection mechanism are arranged on the charging gun; the waterproof mechanism comprises a connecting box,a protection box, a driving assembly, an unlocking assembly and a waterproof assembly; and the driving assembly comprises a mobile plate and two driving units. According to the safe and reliable newenergy vehicle charging pile with the good waterproof effect, through adoption of the waterproof mechanism, rainwater is prevented from entering the charging gun; and through adoption of the protection mechanism, a function of eliminating impurities is also realized.

Owner:QINGDAO SONLI SOFTWARE INFORMATION TECH

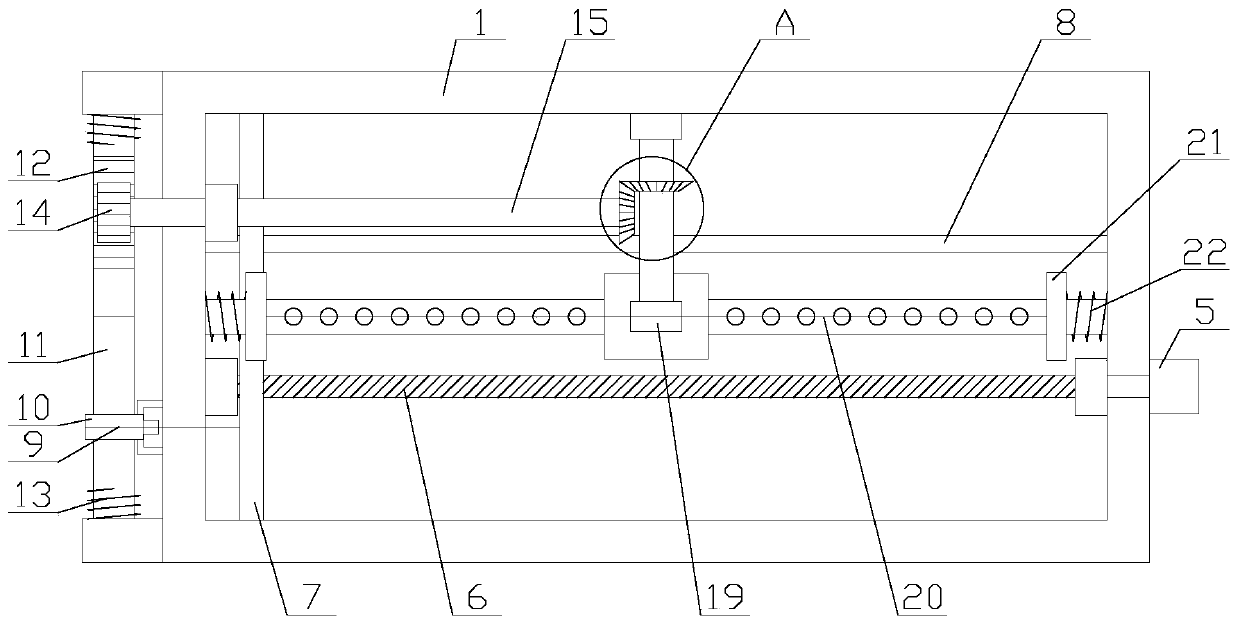

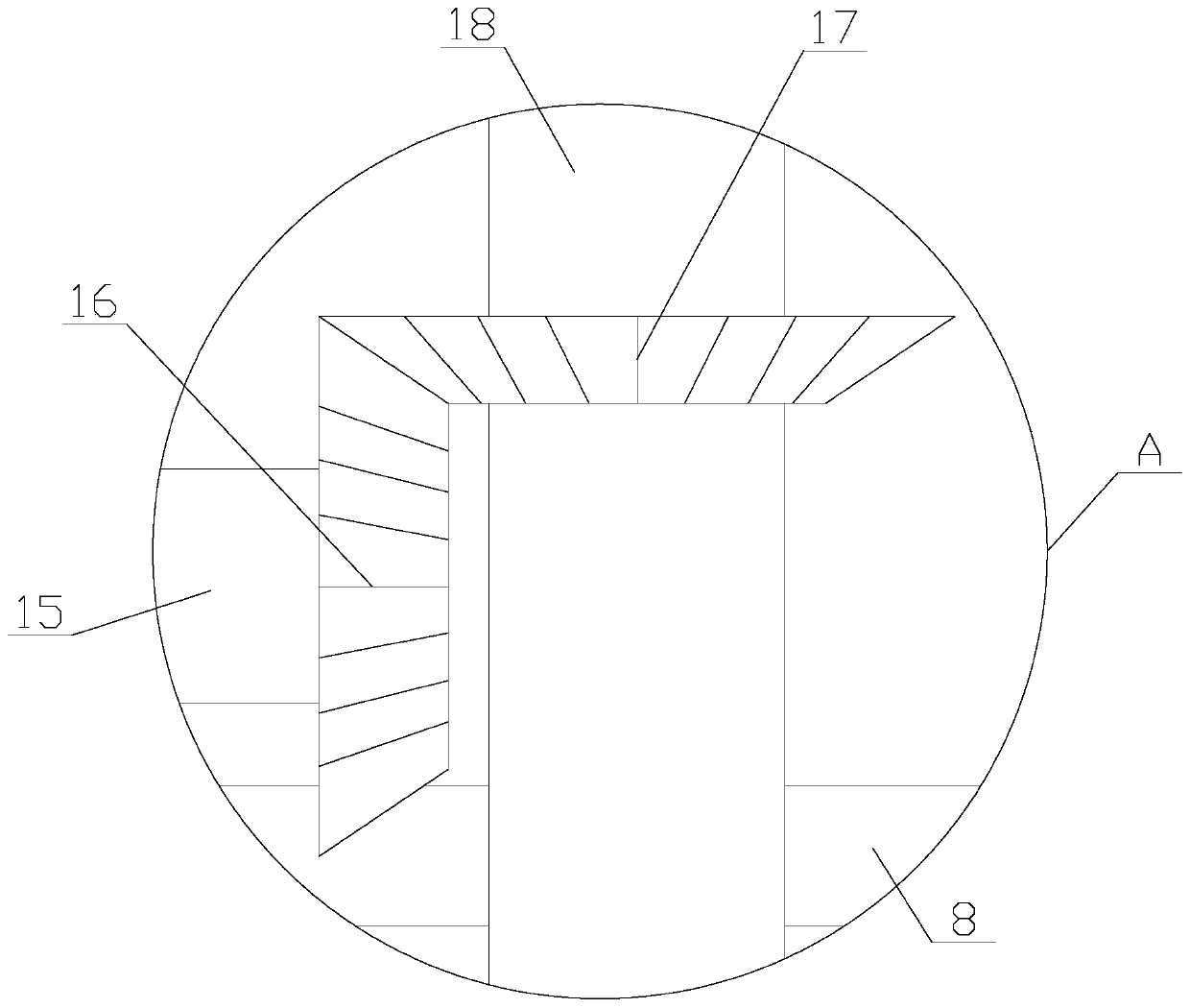

Wafer scribing machine for chip processing

InactiveCN112563198AAvoid affecting workQuality improvementSemiconductor/solid-state device manufacturingWaferEngineering

The invention relates to a wafer scribing machine for chip processing, which comprises a bottom plate, a scribing device, a workbench, a cooling mechanism and two cleaning mechanisms, wherein each cleaning mechanism comprises a fixed box, a fixed column, an air cylinder, a piston, an air inlet pipe, an air outlet pipe, a filter screen, an oiling assembly, a fixed block, a driving block, a connecting rope and two air cylinders; wherein the oiling assembly comprises an oiling box, a driving plate, a driving rod, a power rod, two first springs and two oiling units, the cooling mechanism comprisesa water tank, a water inlet pipe, a water spraying pipe, a supporting box, two water squeezing assemblies and two supporting rods, and each water squeezing assembly comprises a moving plate and two limiting units. According to the wafer scribing machine, through the cleaning mechanisms, the impurity removing function is achieved, the friction force between the scribing device and the wafer is prevented from being increased due to adhesion of chippings, so that the scribing work is prevented from being influenced, the scribing quality is improved, the function of cooling the scribing device isachieved through the cooling mechanism, and the scribing device is prevented from being damaged due to overheating.

Owner:夏志强

Ultraviolet disinfection equipment for sewage treatment

InactiveCN113023970AReduce penetrationImprove stabilityWater/sewage treatment by irradiationSpecific water treatment objectivesUv disinfectionSewage

The invention relates to ultraviolet disinfection equipment for sewage treatment, which comprises a main body and a disinfection lamp, and also comprises an impurity removal mechanism and a cleaning mechanism, the impurity removal mechanism comprises a filter screen, a fixing ring, a driving ring, two fixing assemblies and a plurality of first springs, and the cleaning mechanism comprises a power assembly, a first bearing, a rotating gear and two cleaning assemblies. According to the ultraviolet disinfection equipment for sewage treatment, the impurity removal function of sewage is realized through the impurity removal mechanism, the situation that the penetrating power of a disinfection lamp is reduced due to excessive impurities is avoided, and the situation that the sewage cannot be fully and thoroughly disinfected is prevented, so that the reliability of the equipment is improved. Through the cleaning assemblies, the function of cleaning the inner wall of the main body and the surface of the disinfection lamp is achieved, it is prevented that scale is formed on the surface of the disinfection lamp to block irradiation light of the disinfection lamp, the disinfection effect is prevented from being affected, and therefore the reliability of equipment is improved.

Owner:郝立群

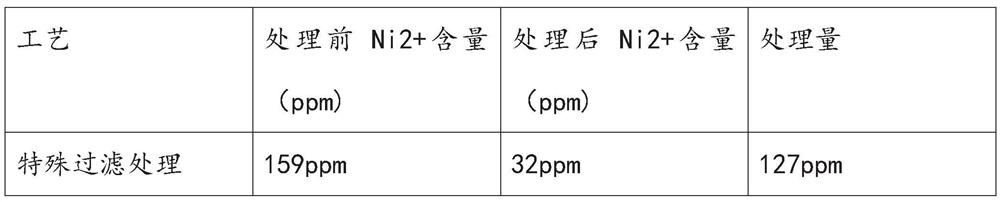

Special treatment process for removing metal nickel impurities in gold plating liquid medicine

PendingCN112813461AEfficient recyclingRealize the function of removing impuritiesPhotography auxillary processesElectrolysis componentsElectrochemical responseElectrolysis

The invention discloses a special treatment process for removing metal nickel impurities in a gold plating liquid medicine, and belongs to the technical field of metal impurity removal. The process comprises the following steps: firstly introducing the gold plating liquid medicine into an ion exchanger for ion exchange treatment, increasing the temperature in the ion exchanger, and reacting for a period of time. According to the method, the ion exchange step is set, so that a concentrated solution of metal ions in the gold plating liquid medicine can be obtained, and meanwhile, the concentrated solution of the metal ions in the gold plating liquid medicine is electrolyzed by utilizing the electrochemical reactor to generate various different metal ions. Other metal ions can be effectively adsorbed through the negative electrode of the electrochemical reactor, and a solution with nickel ions can be led out and is subjected to reaction filtration through the filtering device subjected to special treatment. The device not only can realize the function of removing impurities from some nickel solid metal particles, but also has the effect of removing some nickel metal ions, so that the overall treatment effect of the process is improved.

Owner:SUZHOU PLATER ELECTRONICS CO LTD

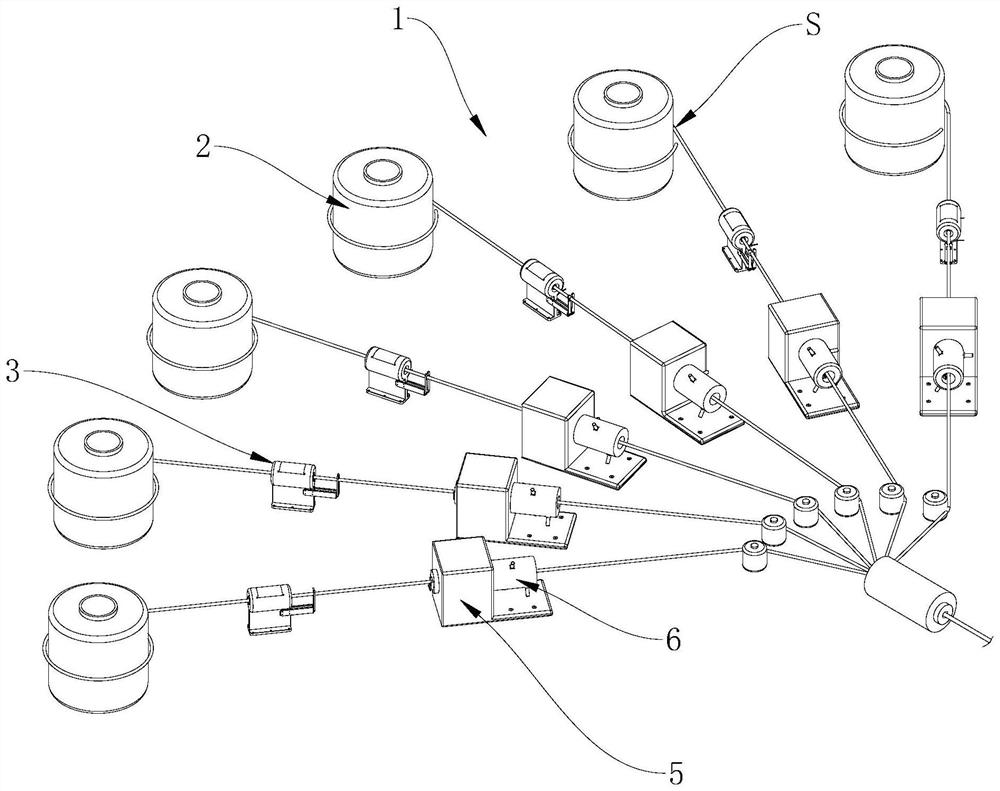

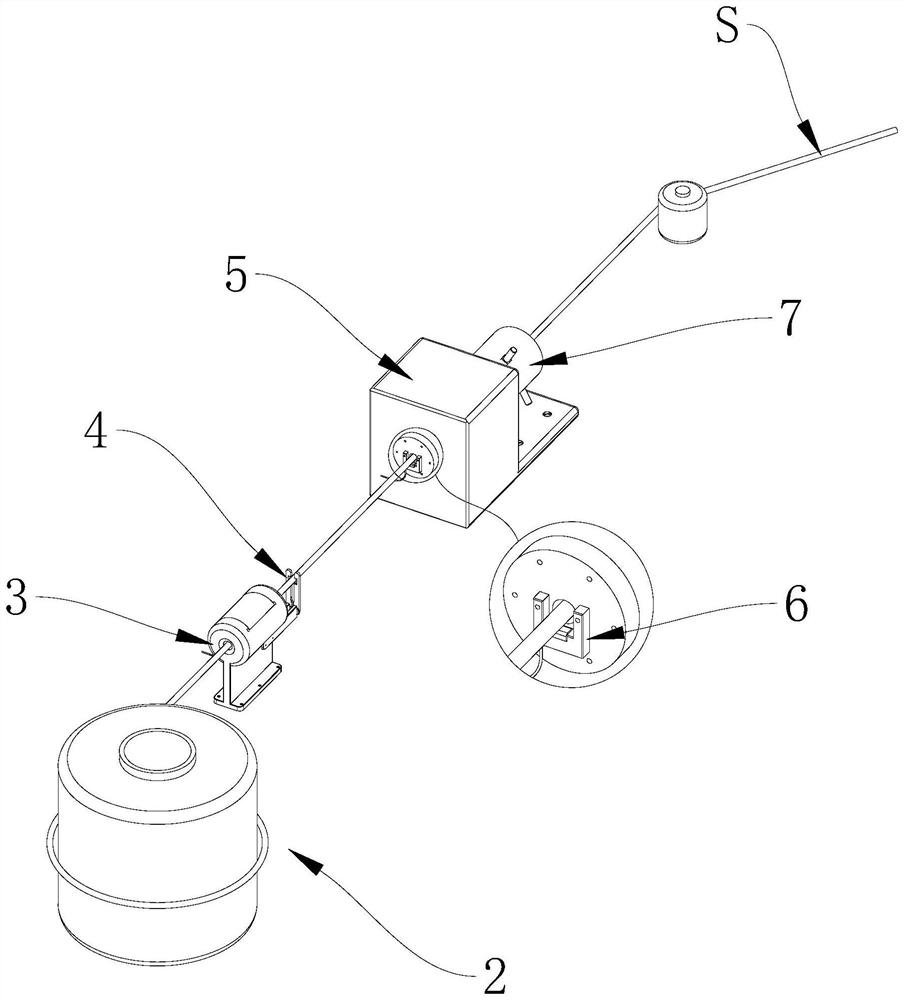

Cotton yarn impurity removal device and method for twisting machine

ActiveCN114753036ARealize the function of removing impuritiesDegree of reductionFibre cleaning/openingTextile disintegration and recoveryYarnDust control

The invention discloses a cotton yarn impurity removal device for a twisting machine and a method thereof, and belongs to the field of twisting machine equipment.The cotton yarn impurity removal device comprises a stretching mechanism used for twisting cotton yarn S. The stretching mechanism comprises a drawing roller arranged at one end, the cotton yarn S is wound on the drawing roller, and the stretching mechanism further comprises a dust removal device and an impurity removal device which are correspondingly arranged; the dust removal device is provided with a clamping roller used for assisting the cotton yarn S to advance, the impurity removal device is provided with a removing structure, a photoelectric sensor is further installed on the side, opposite to the clamping roller, of the impurity removal device, and one end of the cotton yarn S is guided by a stretching mechanism to sequentially penetrate through the dust removal device and the impurity removal device. A cathode and an anode are installed at the two ends in the dust removal machine body respectively, and an adsorption channel used for S wiring of cotton yarn is formed in the middle of the dust removal machine body, the impurity removal function can be achieved, the manual participation degree is reduced, the impurity removal efficiency is improved, and the impurity removal quality is improved.

Owner:台州银基建材有限公司

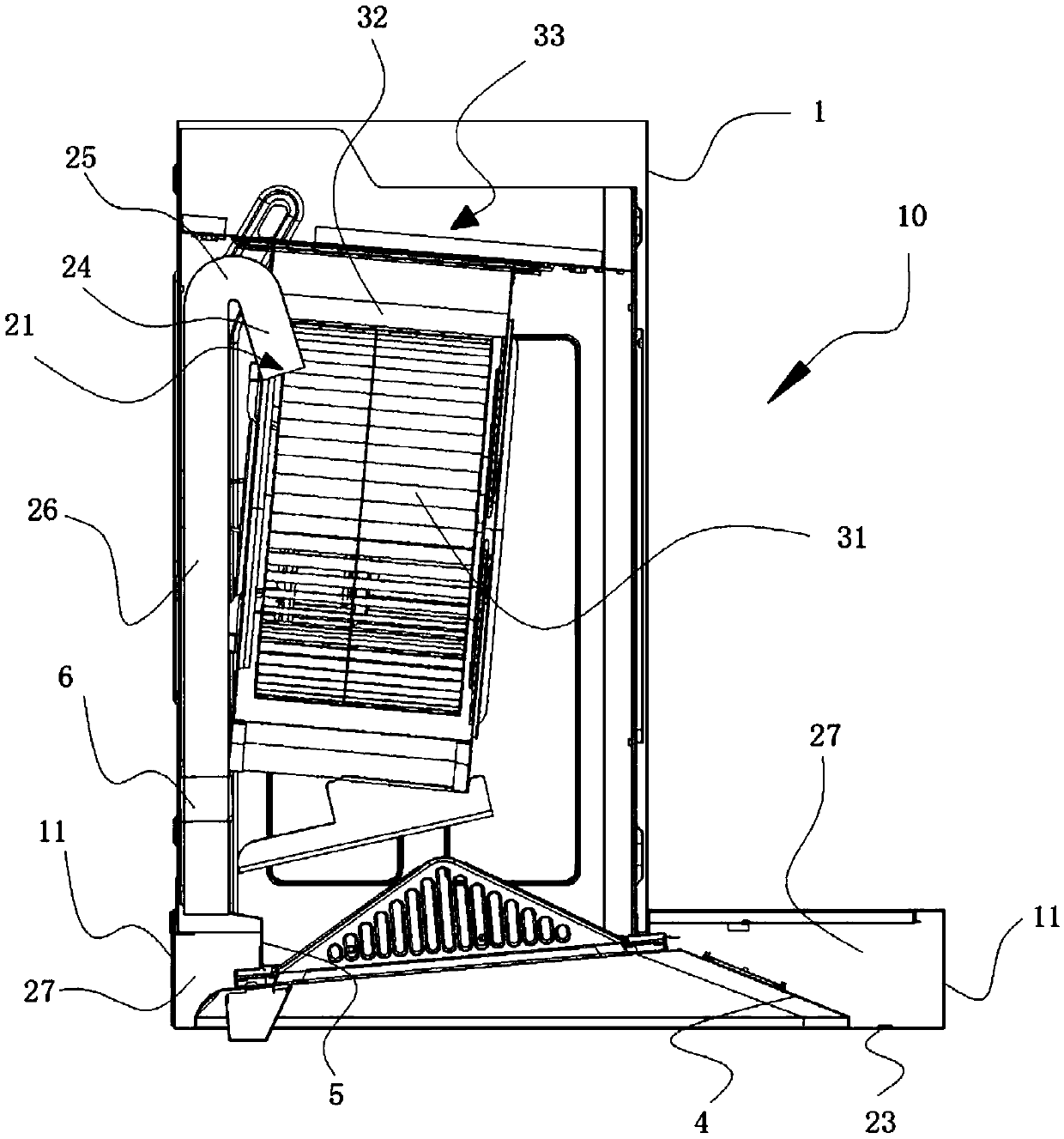

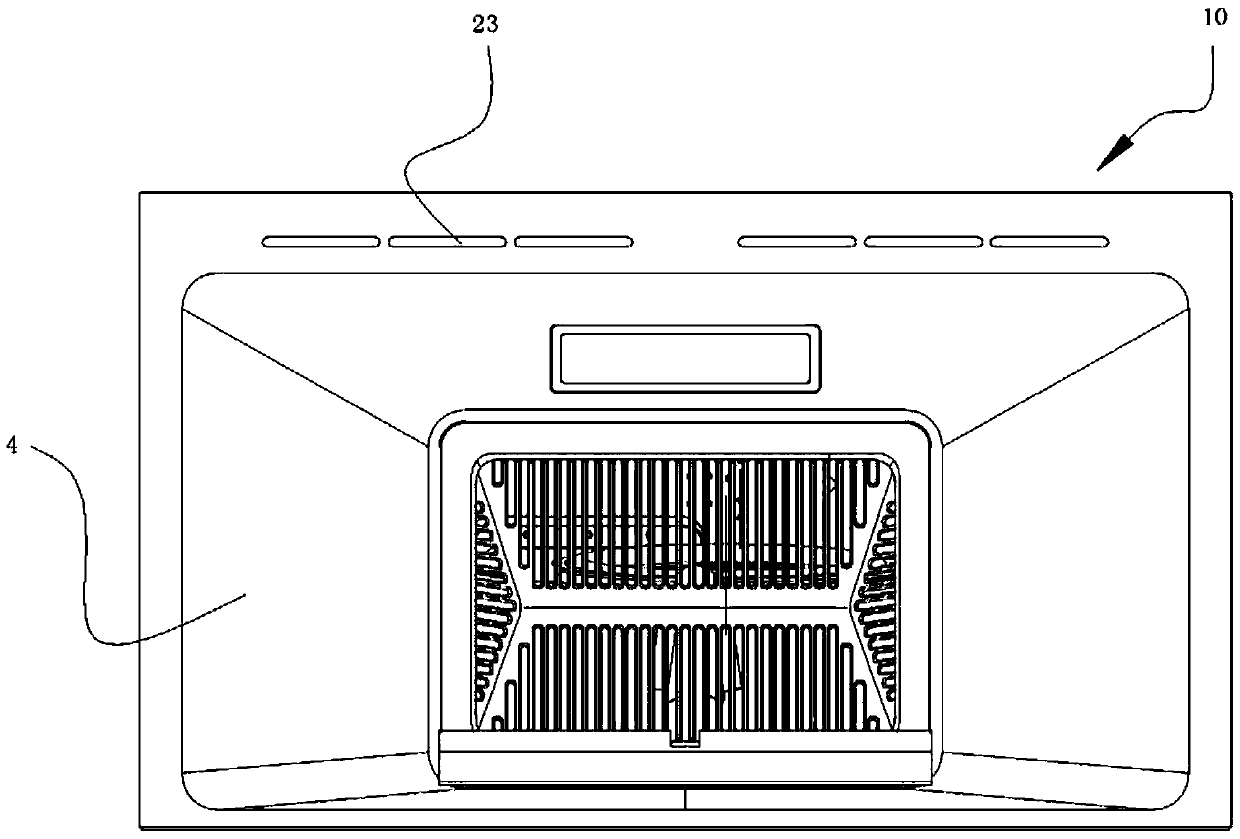

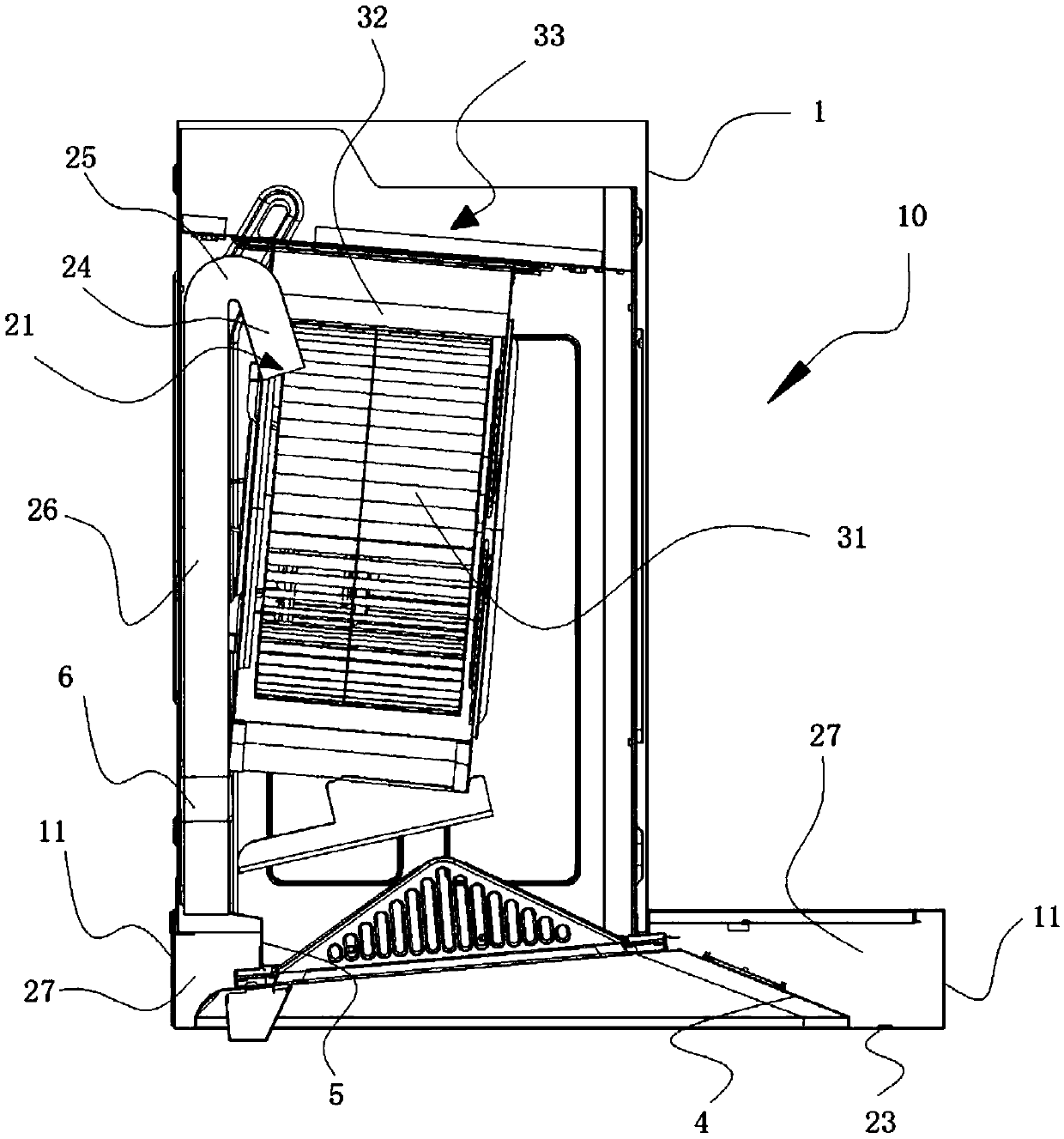

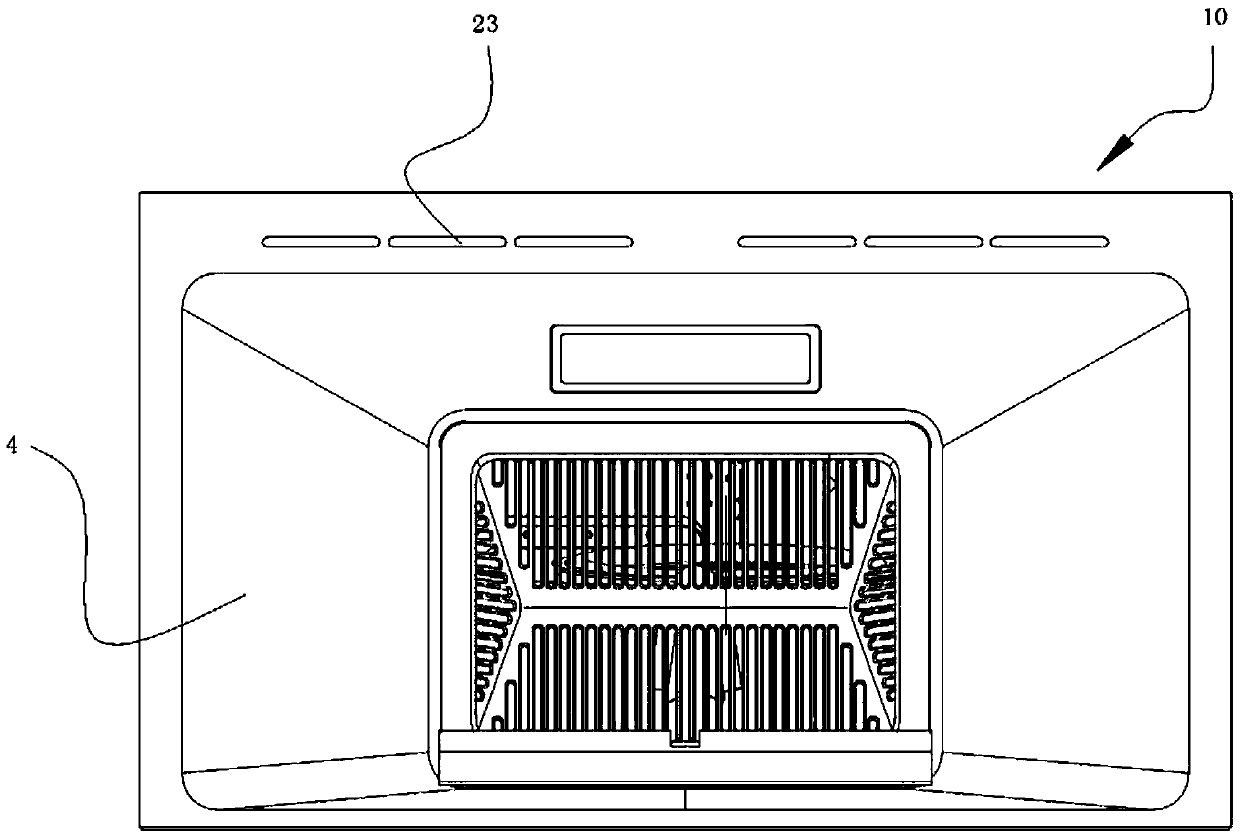

Air curtain range hood

PendingCN110631093AReduce the ability to remove impuritiesImprove the effect of impurity removalDomestic stoves or rangesLighting and heating apparatusProduct gasEngineering

The invention discloses an air curtain range hood. The air curtain range hood comprises an air curtain device and a gas condition acquiring device, wherein the air curtain device is used for forming an air curtain and comprises an impurity removing unit for purifying gas in an air duct; and the gas condition acquiring device controls a working state of the impurity removing unit and / or prompts thegas condition of the air duct and / or prompts an operation suggestion according to the gas condition in the air duct of the air curtain range hood. According to the air curtain range hood, the turning-on condition of the impurity removing unit is improved, the impurity removing unit is turned on only when needed, and the user experience is improved.

Owner:QINGDAO HAIER WISDOM KITCHEN APPLIANCE CO LTD

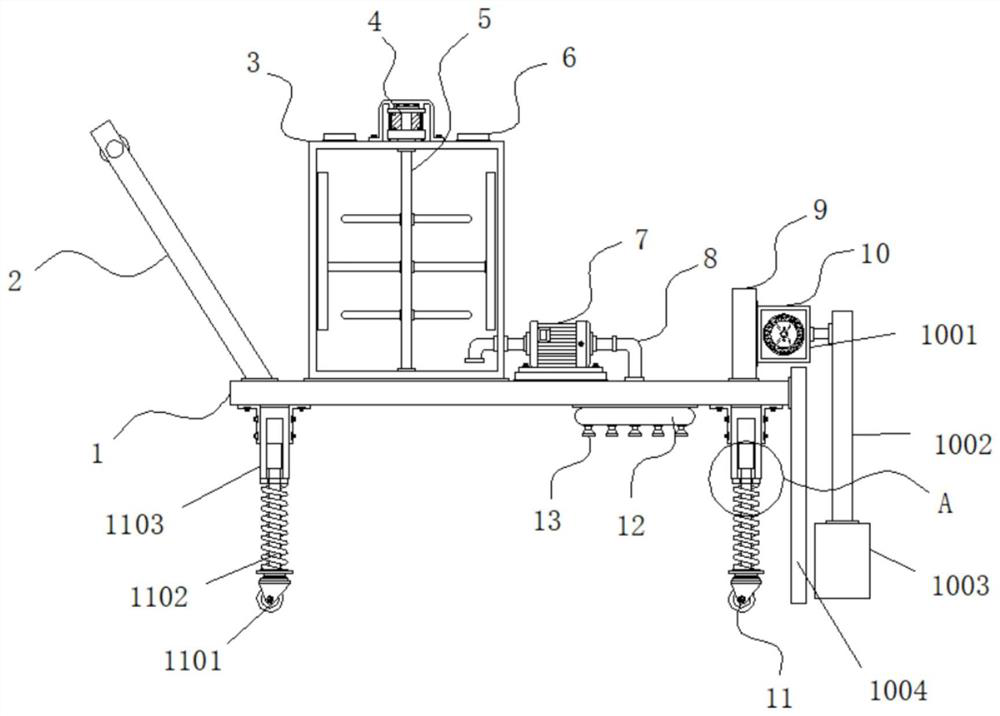

Special remediation agent applying and scattering device for vegetable field soil

PendingCN112496026AAvoid wastingPrevent failure to functionRotary stirring mixersHollow article cleaningSoil remediationEnvironmental engineering

The invention discloses a special remediation agent applying and scattering device for vegetable field soil, and concretely relates to the technical field of vegetable field soil restoration, the special remediation agent applying and scattering device comprises a bottom plate and a liquid box, one side of the top end of the bottom plate is fixedly connected with an armrest, and one side of the armrest is provided with the liquid box. By arranging the shell, the connecting rod, the push plate, the impurity removing plate, the sliding block, a threaded shaft, a driving block, a servo motor anda sliding groove, when the device is used, the impurity removing plate can scrape impurities on the surface of soil, at the moment, the servo motor is started, the servo motor drives the threaded shaft to rotate, and the threaded shaft drives the driving block to move front and back; the driving block drives the connecting rod on one side of the sliding block to move forwards and backwards, and the push plate at the bottom of the connecting rod pushes away impurities at the front end of the impurity removing plate, so that the impurities can be removed while being pushed away, the situation that a large amount of remediation agent cannot play a role when sprayed on the impurities on the soil surface can be prevented, and waste of the remediation agent is avoided; and use requirements can be met.

Owner:湖南博川农业发展有限责任公司

Air curtain range hood

PendingCN110631098AIncrease airflow resistanceIncreased control burdenDomestic stoves or rangesLighting and heating apparatusEngineeringAirflow

The invention discloses an air curtain range hood, which includes an air curtain device and a gas condition acquisition device. The air curtain device is used for forming an air curtain, and includesan impurity removal unit for purifying gas in an air duct of the air curtain of the air curtain device, and the gas condition acquisition device is used for obtaining the surrounding environment and / or equipment internal gas conditions, is connected with the air curtain device, and controls a working state of the impurity removal unit and / or prompts obtained results and / or prompts operation suggestions according to the results obtained by the gas condition acquisition device. According to the introduced air curtain range hood, air curtain airflow generated by the air curtain device is subjected to impurity removal, the quality of the air curtain airflow is ensured, and the user experience is improved.

Owner:QINGDAO HAIER WISDOM KITCHEN APPLIANCE CO LTD

A kind of uv photolysis air purification equipment with dust removal function

ActiveCN111649401BRealize dust removal functionRealize the function of removing impuritiesCombination devicesMechanical apparatusDust controlAir cleaning

The invention relates to a UV photolysis air purification device with dust removal function, which includes a main body, an air inlet pipe, an air outlet pipe and a UV lamp, and also includes a dust removal mechanism and a heat dissipation mechanism. The dust removal mechanism includes a dust removal box, a filter cartridge, a hose, Connecting pipe, power assembly, ring, two limit assemblies, two impurity removal assemblies and several struts, the heat dissipation mechanism includes a sponge, a collection box, a fixed box, a pumping assembly, a connection box and two water spray assemblies, The UV photolysis air purification equipment with dust removal function realizes the function of dedusting the exhaust gas through the dust removal mechanism, preventing the dust in the exhaust gas from covering the UV lamp and affecting the waste gas treatment work of the UV lamp, and spraying on the sponge through the heat dissipation mechanism Clean water can cool down the surrounding air, thereby cooling down the UV lamp, preventing the UV lamp from being damaged due to overheating, and improving the reliability of the equipment.

Owner:深圳市利微成科技有限公司

Method and apparatus for recovery of remaining alumina and dust collection in alumina discharge station

ActiveCN102268696BShort processEnable in-place recyclingCombination devicesWear resistantThree stage

Owner:傅文渊

Moisture measuring instrument with high reliability

InactiveCN112557242ARealize the stirring functionReduce cloggingWeighing by removing componentDispersed particle filtrationMeasuring instrumentHeater Rod

The invention relates to a moisture measuring instrument with high reliability which comprises a main body, a sealing plate, a storage box, a bottom plate, a weighing device, two supporting blocks andfour fixing blocks, and further comprises an impurity removal mechanism and two stirring mechanisms, wherein the impurity removal mechanism comprises a fixing box, a heating rod, two exhaust pipes and two impurity removal assemblies. The stirring mechanism includes a motor, a screw rod, a rotating shaft, a first bearing, a second bearing, a sliding block, a stirring assembly, a connecting rod andtwo supporting rods. Through the impurity removing mechanism, the function of removing impurities from air entering the main body is achieved, the situation that dust adheres to materials, and consequently the weight of the materials is increased is avoided, thereby avoiding affecting the detection accuracy, the stirring mechanism realizes the function of stirring the materials inside the storagebox, the situation that the materials are accumulated together and cannot be fully dried is avoided, and therefore the influence on the drying efficiency is avoided.

Owner:武桂英

Pre-condensation and impurity removal equipment for mixing natural gas synergistic additives

ActiveCN108913250BRealize the function of removing impuritiesImprove product quality stabilityGaseous fuelsSteam/vapor condensersRefrigerationPhysics

The invention relates to the technical field of natural gas synergistic processing equipment, and particularly relates to a preposed condensation impurity removing device for adding a natural gas synergistic additive. A natural gas pipe is a square pipe; the lower pipe wall of the natural gas pipe is provided with an inlet hole and an outlet hole; a condensation ring is a circular ring; the upperpart of the condensation ring extends into the natural gas pipe through an inlet hole and an outlet hole; the top of the condensation ring is close to the top of the natural gas pipe; condensation ring supporting rollers are arranged under the condensation ring and are used for supporting the lower edge of the condensation ring; condensation ring positioning rollers are arranged in a condensationring circle and are matched with the condensation ring supporting rollers to clamp the condensation ring, and positioning is realized; and a plurality of condensation ring excitation electromagnets are uniformly distributed around the part, outside the natural gas pipe, of the condensation pipe. According to the invention, a condensation ring circulation working principle of a demagnetization refrigeration principle is adopted, so that an impurity removing effect on impurities such as water vapor, volatile gaseous long-chain hydrocarbon and the like in natural gas is realized, and the productquality stability after operation of follow-up natural gas additive is effectively improved.

Owner:石嘴山市讯通实业有限责任公司

Solar panel etching process for preventing EL pollution

ActiveCN106848004AIncrease oxygen contentImprove efficiencyFinal product manufacturePhotovoltaic energy generationEtchingOxygen

The invention relates to the technical field of battery piece etching, and particularly relates to a solar panel etching process for preventing the EL pollution. The process comprises the steps that in step 1, plating film is prepared, a layer of aluminum film is plated on both the upper and lower surfaces of the to-be-etched silicon wafer; in step 2, primary removal of impurities is conducted; in step 3, secondary removal of impurities is conducted, then the film is soaked in a primary etching liquid; in step 4, the remaining aluminum film is removed; in step 5, etching is prepared; and in step 6, etching is conducted. Through the effect of aluminum film, and oxygen and variable temperature heating at the primary removal of impurities, the removal of impurities on silicon wafer is achieved, then through the reaction role of the primary etching liquid and aluminum film at the secondary removal of impurities, the aluminum film is made to further adsorb the impurities inside the silicon wafer, to better achieve the function of removing impurities for silicon wafer, in the wafer etching process, through the function of the primary removal of impurities and the secondary removal of impurities, EL pollution is effectively prevented while etching, the producing of electric leakage battery boards and hidden crack battery boards is reduced and very effective.

Owner:TONGWEI SOLAR (ANHUI) CO LTD

A solar cell panel etching process to prevent el pollution

ActiveCN106848004BIncrease oxygen contentImprove efficiencyFinal product manufacturePhotovoltaic energy generationEtchingOxygen

The invention relates to the technical field of battery piece etching, and particularly relates to a solar panel etching process for preventing the EL pollution. The process comprises the steps that in step 1, plating film is prepared, a layer of aluminum film is plated on both the upper and lower surfaces of the to-be-etched silicon wafer; in step 2, primary removal of impurities is conducted; in step 3, secondary removal of impurities is conducted, then the film is soaked in a primary etching liquid; in step 4, the remaining aluminum film is removed; in step 5, etching is prepared; and in step 6, etching is conducted. Through the effect of aluminum film, and oxygen and variable temperature heating at the primary removal of impurities, the removal of impurities on silicon wafer is achieved, then through the reaction role of the primary etching liquid and aluminum film at the secondary removal of impurities, the aluminum film is made to further adsorb the impurities inside the silicon wafer, to better achieve the function of removing impurities for silicon wafer, in the wafer etching process, through the function of the primary removal of impurities and the secondary removal of impurities, EL pollution is effectively prevented while etching, the producing of electric leakage battery boards and hidden crack battery boards is reduced and very effective.

Owner:TONGWEI SOLAR (ANHUI) CO LTD

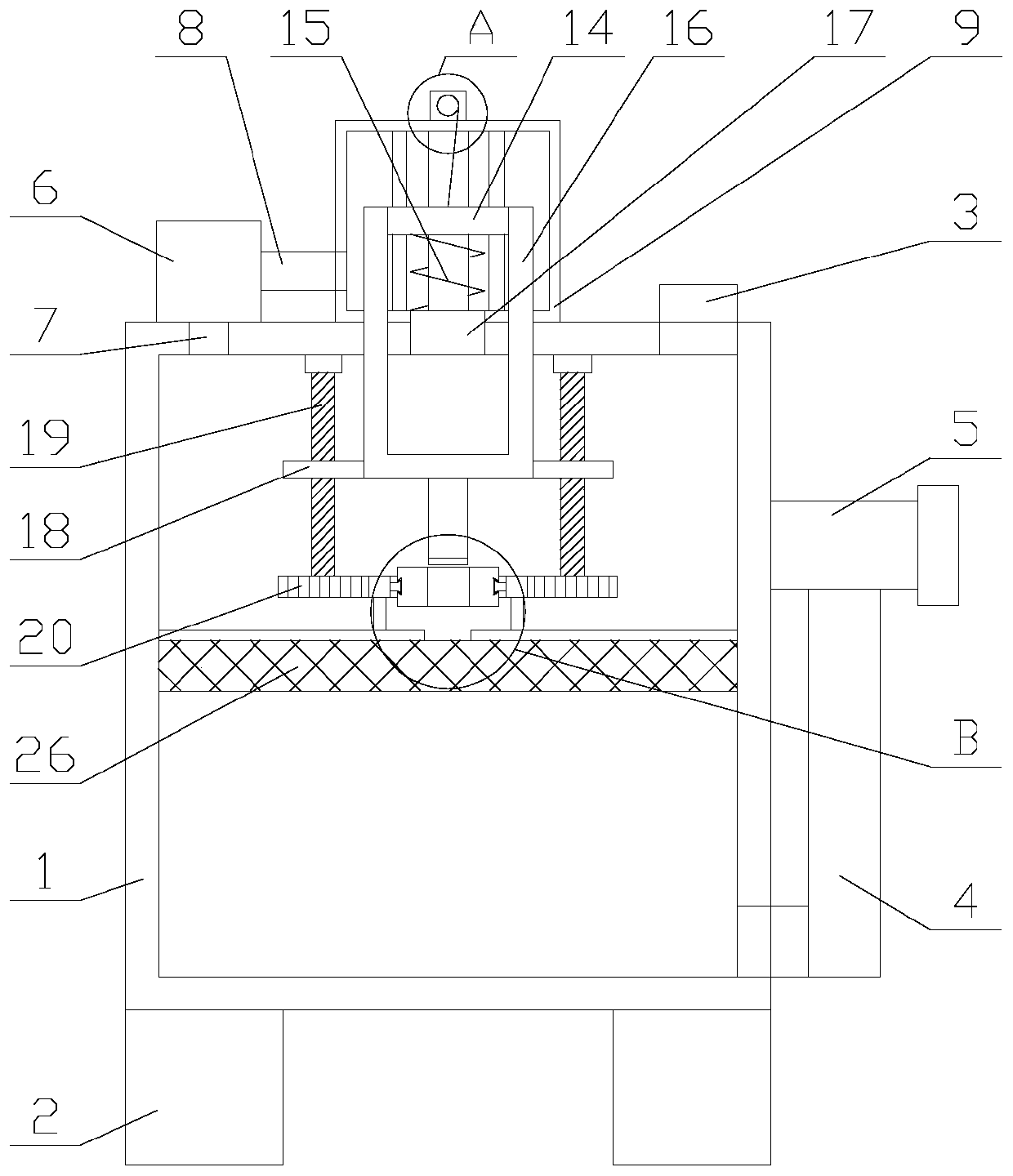

High-voltage cable checking instrument based on electric power safety

PendingCN114674923ARealize reciprocating motionRealize touch and swipeAnalysing solids using sonic/ultrasonic/infrasonic wavesFilament handlingElectric machineStructural engineering

The invention discloses a high-voltage cable checking instrument based on electric power safety, and belongs to the technical field of cable checking, the high-voltage cable checking instrument comprises a base, the top of the base is fixedly provided with an ultrasonic checking machine and a take-up mechanism, the ultrasonic checking machine is internally provided with a cable conduction platform, and the side wall of the ultrasonic checking machine is provided with two inlet grooves; the two inlet grooves are both provided with detection cables, a driving motor is fixedly installed on the side wall of the ultrasonic troubleshooting machine, a conduction assembly is fixedly installed at one end of an output shaft of the driving motor and used for detecting stable conduction of the cables, and a magnetic brushing assembly and a turbulent flow assembly are arranged on the inner wall of the top face of the ultrasonic troubleshooting machine. According to the invention, through the arrangement of the driving assembly and the magnetic brushing assembly, and through the design of the linkage assembly, the magnetic impurity removal function in the cable conduction process is realized, so that the precision of a subsequent troubleshooting result is stably improved, and adverse effects on troubleshooting are avoided.

Owner:李勇为

Sand blasting equipment with moisture-proof and filtering functions

ActiveCN111267008AReduce moisture contentReduces chances of getting wetBlast gunsAbrasive machine appurtenancesSand blastingGear wheel

The invention relates to sand blasting equipment with moisture-proof and filtering functions. The sand blasting equipment with moisture-proof and filtering functions comprises a main body, a feed pipe, a discharge pipe, a spray gun and two supporting columns, and further comprises a drying mechanism and a filtering mechanism. The drying mechanism comprises an air extraction assembly, a fixed box,a refrigeration rod, a connecting ring, a driving assembly, a support and a spring. The filtering mechanism comprises a filtering net, a fixed block, a first gear, a limiting assembly, vibrating rods,two cleaning assemblies and two rotating assemblies. According to the sand blasting equipment with moisture-proof and filtering functions, through the drying mechanism, the water content in the air inside the main body is reduced, so that the probability of moisture exposure of the materials inside the main body is reduced, material agglomeration is prevented, and the practicability of the equipment is improved; and through the filtering mechanism, the function of removing impurities from the materials is realized, the impurities are prevented from blocking the spray gun, and the probabilityof spray gun damage is reduced.

Owner:日达智造科技(如皋)有限公司

A paint spraying equipment with impurity removal function

ActiveCN112536175BRealize the function of removing impuritiesQuality improvementSpraying apparatusProcess engineeringWorkbench

The invention relates to a paint spraying equipment with the function of removing impurities, which includes a workbench, a top plate, a material box, a material pipe, a paint spraying pipe and two support rods, and also includes an impurity removing mechanism and a feeding mechanism, and the feeding mechanism includes a feeding box, Feeding pipe, feeding pipe, sealing plug, connecting rod, moving plate, cleaning assembly and two cylinders, the impurity removal mechanism includes an impurity removal net, a vibrating assembly and two connection assemblies, and the painting equipment with impurity removal function passes through The feeding mechanism realizes the function of cleaning the inner wall of the feeding box, prevents the paint on the inner wall of the feeding box from agglomerating into blocks, reduces the probability of blocking the feeding box after long-term use, and avoids affecting the feeding work, thus improving the reliability of the equipment Through the impurity removal mechanism, the function of removing impurities in the paint is realized, the amount of impurities in the paint is reduced, and impurities are prevented from blocking the paint spraying pipe, thereby preventing the impact on the painting work and improving the quality of the paint spraying. The reliability of the equipment is improved.

Owner:浙江佐川科技有限公司

Anti-blocking spraying equipment

InactiveCN112915609ARealize the function of removing impuritiesLight in massStationary filtering element filtersEngineeringStructural engineering

The invention relates to anti-blocking spraying equipment which comprises a base plate, a workbench, a material box, a material pipe, a paint spraying pipe and two supporting rods and further comprises an impurity removing mechanism and a cleaning mechanism, wherein the impurity removing mechanism comprises a filter cartridge, a fixing ring, a driving ring, two driving assemblies and a plurality of connecting blocks, and the cleaning mechanism comprises a fixing box, two inflation assemblies and two cleaning assemblies. According to the anti-blocking spraying equipment, the function of removing impurities of paint is achieved through the impurity removing mechanism, the situation that the quality of the paint is reduced due to excessive impurities is avoided, the influence on the spraying effect is avoided accordingly, the reliability of the equipment is improved accordingly, the paint is not prone to adhering to the inner wall of the feeding pipe through the cleaning mechanism in two different modes, therefore, the function of cleaning the feeding pipe is achieved, the interior of the feeding pipe cannot be blocked due to solidification of residual paint on the inner wall of the feeding pipe, the influence on feeding work is avoided, and the reliability of equipment is improved.

Owner:南京塘贝环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com