Special remediation agent applying and scattering device for vegetable field soil

A repairing agent and soil technology, which is applied in the field of special soil repairing agent applicator for vegetable fields, can solve the problems that the special soil repairing agent cannot be mixed and stirred, and the repairing liquid is easy to remain on the side wall of the liquid tank, sedimentation, etc., so as to prevent precipitation and improve The effect of service life and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

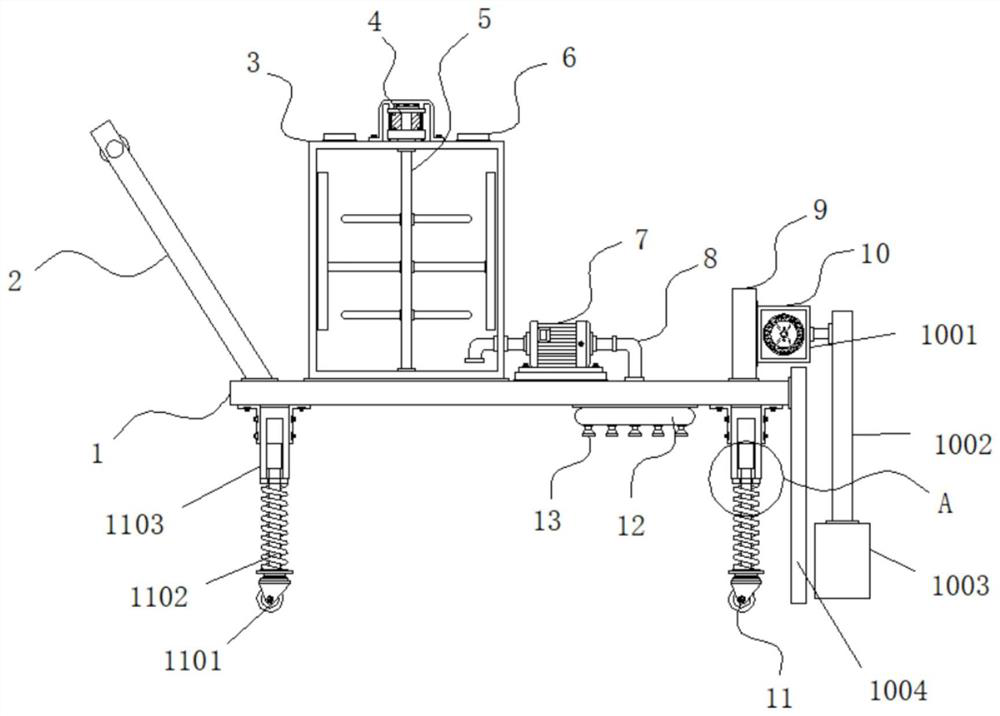

[0026] Example 1: See Figure 1-4 , a vegetable field soil restoration agent spreading device, comprising a bottom plate 1 and a liquid tank 3, one side of the top of the bottom plate 1 is fixedly connected with a handrail 2, one side of the handrail 2 is provided with a liquid tank 3, two tops of the liquid tank 3 There are liquid inlets 6 on each side, and a water pump 7 is fixedly connected to one side of the liquid tank 3. The model of the water pump 7 can be 300QSZ-3.4-13, and the output end of the water pump 7 is fixedly connected to a water pipe 8. The water diversion chamber 12 is fixedly connected, the bottom of the water diversion chamber 12 is fixedly connected with several groups of sprinkler heads 13, the other side of the top of the bottom plate 1 is fixedly connected with a fixed plate 9, and one side of the fixed plate 9 is provided with a cleaning mechanism 10. The four corners at the bottom of the bottom plate 1 are respectively provided with mobile shock abs...

Embodiment 2

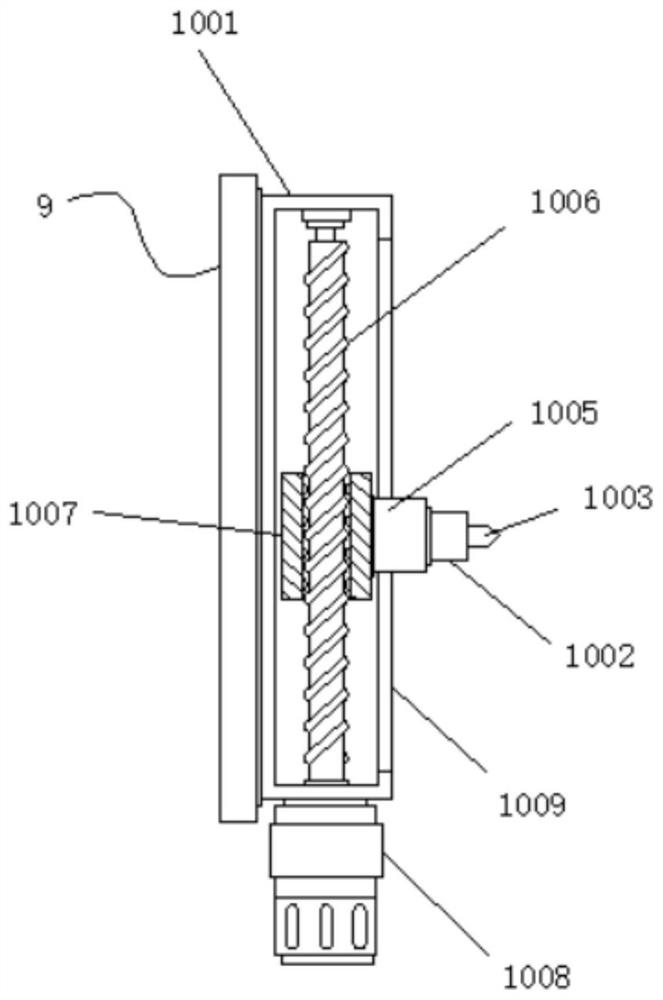

[0030] Embodiment 2: The cleaning mechanism 10 is composed of a housing 1001, a connecting rod 1002, a push plate 1003, a cleaning plate 1004, a sliding block 1005, a threaded shaft 1006, a driving block 1007, a servo motor 1008 and a sliding groove 1009. The housing 1001 Fixedly connected to one side of the fixed plate 9, the inside of the casing 1001 is movably connected with a threaded shaft 1006, and the outside of the threaded shaft 1006 is movably connected with a drive block 1007, and the inside of the casing 1001 side is provided with a slide groove 1009, and the drive block 1007 One side of the sliding block 1005 is fixedly connected with a sliding block 1005, one side of the sliding block 1005 penetrates to one side of the sliding groove 1009 and is fixedly connected with a connecting rod 1002, the bottom end of the connecting rod 1002 is fixedly connected with a push plate 1003, and the cleaning plate 1004 is fixed Connected to one side of the bottom plate 1, the ser...

Embodiment 3

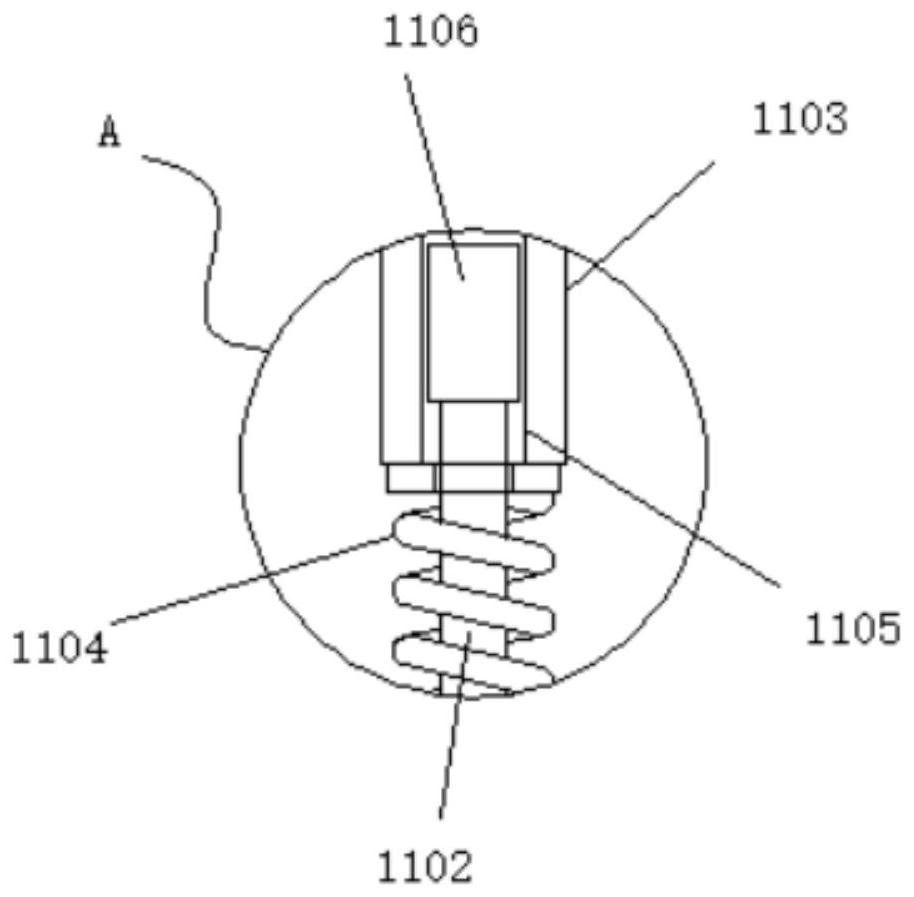

[0034] Embodiment 3: The mobile damping structure 11 is composed of casters 1101, struts 1102, support columns 1103, springs 1104, chute 1105 and slider 1106. The support columns 1103 are fixedly connected to the four corners of the bottom end of the base plate 1 respectively, supporting The inside of the bottom of the column 1103 is provided with a chute 1105, and the inside of the chute 1105 is provided with a slider 1106. The bottom of the slider 1106 is fixedly connected with a pole 1102, and the outside of the pole 1102 is sleeved with a spring 1104. The bottom end is fixedly connected with a caster 1101, and the two ends of the spring 1104 are respectively fixedly connected with the bottom end of the support column 1103 and the top end of the caster 1101;

[0035] The slider 1106 runs through the inside of the chute 1105, and a sliding connection is formed between the chute 1105 and the slider 1106;

[0036] Specifically, such as figure 1 with image 3 As shown, when i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com