Cotton yarn impurity removal device and method for twisting machine

A technology of twisting machine and dust removal device, which is applied in textiles and papermaking, fiber treatment, fiber cleaning, etc. It can solve the problems of unable to discharge cotton yarn impurities for a long time and efficiently, reduce the quality of cotton yarn, and laboriously, so as to reduce the degree of manual participation. , The effect of improving the quality of impurity removal and improving the efficiency of impurity removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

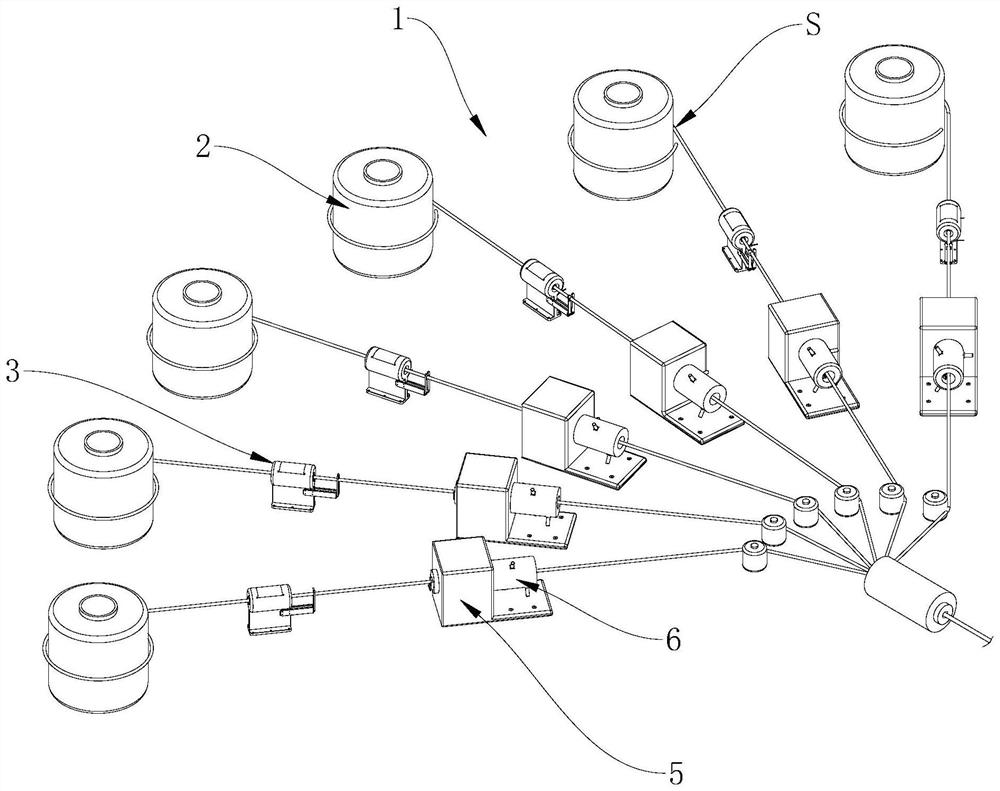

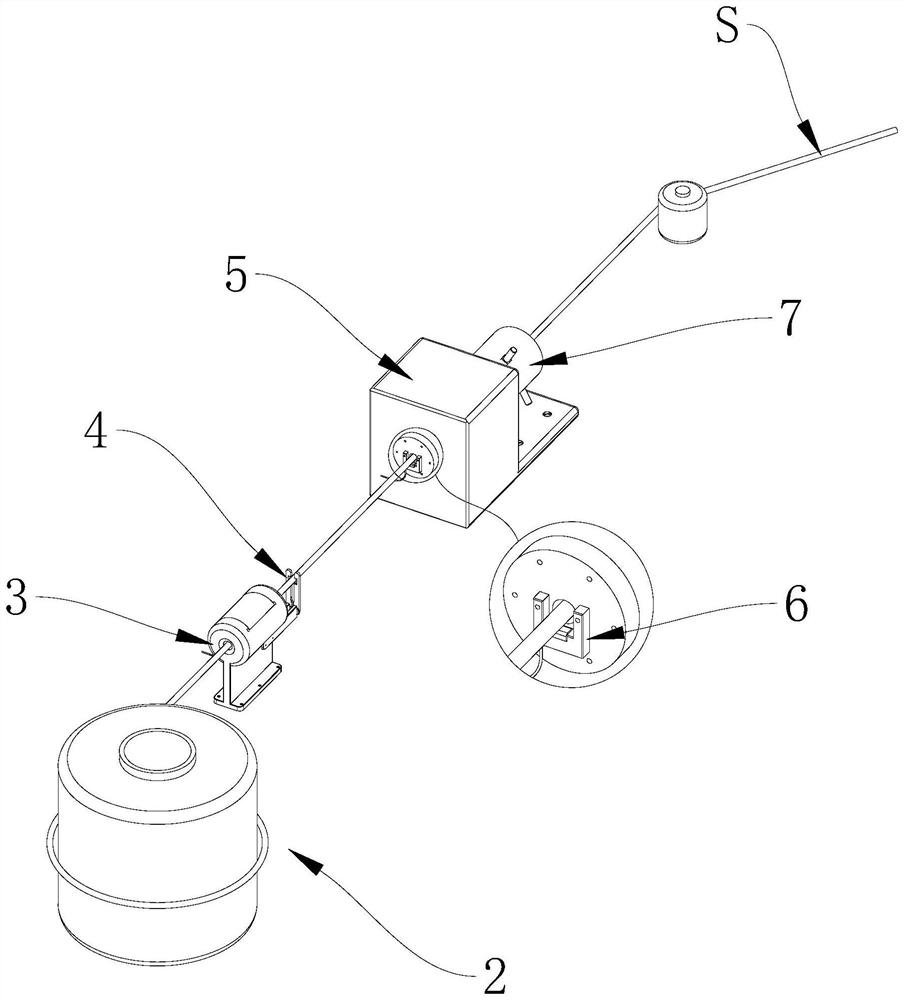

[0035] see Figure 1-9 , a cotton yarn impurity removal device for a twisting machine, comprising a drafting mechanism 1 for twisting cotton yarn S, the drafting mechanism 1 includes a drafting roller 2 arranged at one end, and the cotton yarn S is wound around the drafting roller 2. Rolla 2 on;

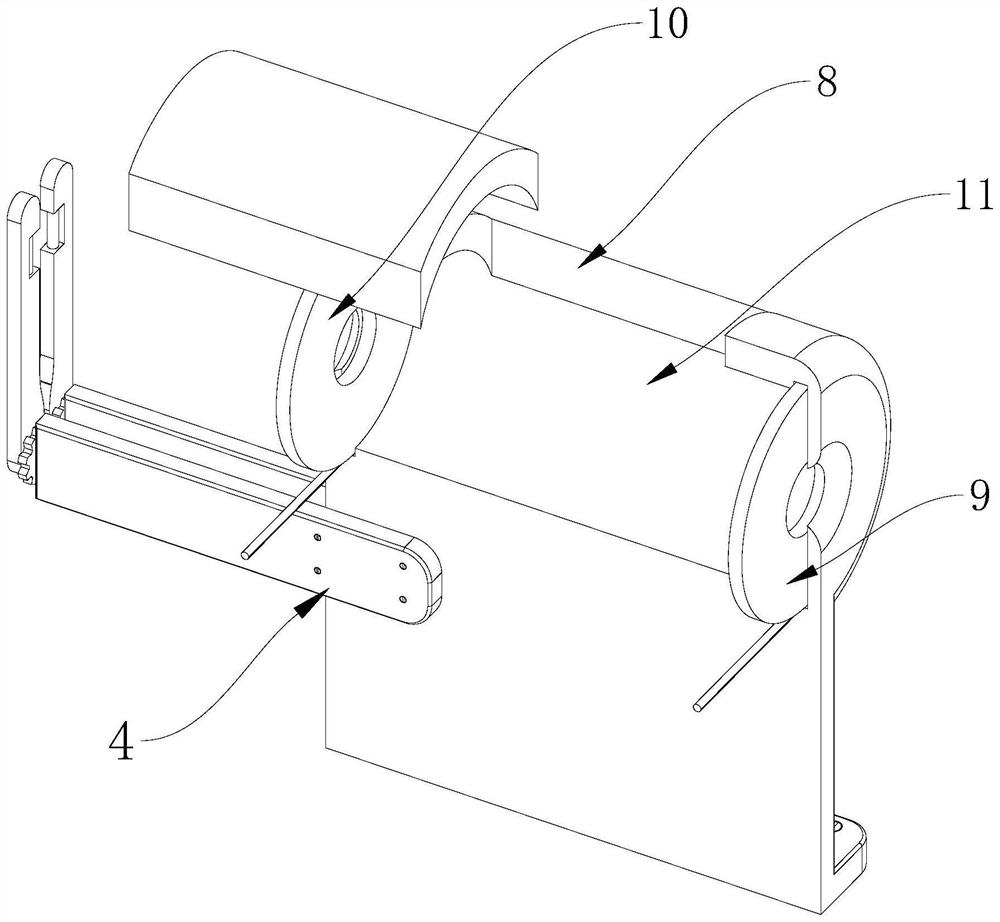

[0036] The pulling mechanism 1 also includes a dust removal device 3 and an impurity removal device 5 arranged in a corresponding arrangement. The dust removal device 3 is provided with a clamping roller 4 for assisting the cotton yarn S to travel. Structure 6, a photoelectric sensor 7 is also installed on the side of the impurity removing device 5 opposite to the nip roller 4;

[0037] One end of the cotton yarn S is guided by the stretching mechanism 1 to pass through the dust removal device 3 and the impurity removal device 5 in sequence.

[0038] Further, the multiple strands of the cotton yarn S pass through the dust removal device 3 and the impurity removal device 5 in sequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com