Special treatment process for removing metal nickel impurities in gold plating liquid medicine

A special treatment, metal nickel technology, applied in the field of special treatment process to solve the metal nickel impurities in the gold plating solution, can solve the problems of poor removal effect, inability to remove metal nickel, and general removal effect of metal nickel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

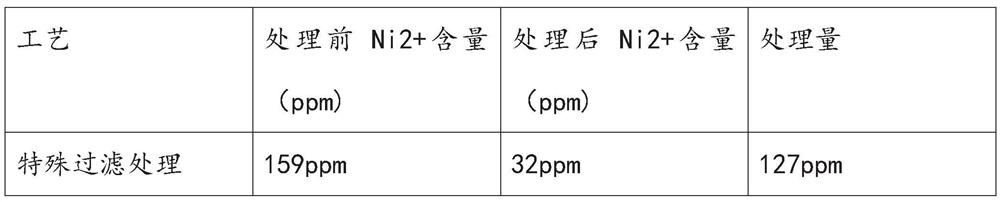

Image

Examples

Embodiment 1

[0038] The present invention provides a technical solution: a special treatment process for solving metal nickel impurities in gold-plating liquid, comprising the following steps:

[0039] S1. First introduce the gold-plating liquid into the ion exchanger for ion exchange treatment, increase the temperature in the ion exchanger to 150°C, and react for 25 minutes to obtain a concentrated solution of metal ions in the gold-plated liquid, and then introduce the resulting concentrated liquid into the concentrated In the liquid tank, the separated water is reintroduced into the container for storage;

[0040] S2. Introduce the concentrated solution obtained in the step S1 into the electrochemical reactor, perform a certain degree of electrolytic treatment on the concentrated solution to obtain an electrolyte, and some other impurity metals are adsorbed on the cathode, and the cathode of the electrochemical reactor Using carbon materials;

[0041] S3. For special treatment in the f...

Embodiment 2

[0050] The present invention provides a technical solution: a special treatment process for solving metal nickel impurities in gold-plating liquid, comprising the following steps:

[0051] S1. First, introduce the gold plating solution into the ion exchanger for ion exchange treatment, increase the temperature in the ion exchanger to 160°C, and react for 30 minutes to obtain a concentrated solution of metal ions in the gold plating solution, and then introduce the resulting concentrated solution into the concentrated solution. In the liquid tank, the separated water is reintroduced into the container for storage;

[0052] S2. Introduce the concentrated solution obtained in the step S1 into the electrochemical reactor, perform a certain degree of electrolytic treatment on the concentrated solution to obtain an electrolyte, and some other impurity metals are adsorbed on the cathode, and the cathode of the electrochemical reactor Using carbon materials;

[0053] S3. For special tr...

Embodiment 3

[0062] The present invention provides a technical solution: a special treatment process for solving metal nickel impurities in gold-plating liquid, comprising the following steps:

[0063] S1. First introduce the gold-plating liquid into the ion exchanger for ion exchange treatment, increase the temperature in the ion exchanger to 165°C, and react for 32 minutes to obtain a concentrated solution of metal ions in the gold-plated liquid, and then introduce the resulting concentrated liquid into the concentrated In the liquid tank, the separated water is reintroduced into the container for storage;

[0064] S2. Introduce the concentrated solution obtained in the step S1 into the electrochemical reactor, perform a certain degree of electrolytic treatment on the concentrated solution to obtain an electrolyte, and some other impurity metals are adsorbed on the cathode, and the cathode of the electrochemical reactor Using carbon materials;

[0065] S3. For special treatment in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com