Feeding equipment with impurity removal and anti-blocking functions for feed production

A technology of anti-blocking and tools, applied in the direction of feed, application, transportation and packaging, etc., can solve the problems of inability to remove debris, poor feeding, and blockage of the feeding pipe, so as to improve the dredging effect, smooth feeding, and avoid The effect of clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

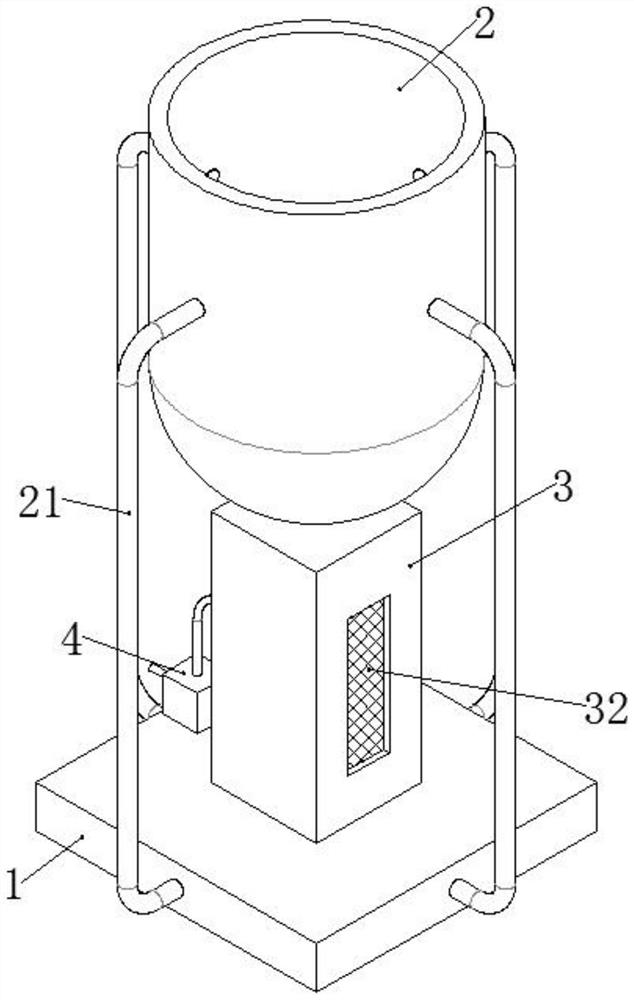

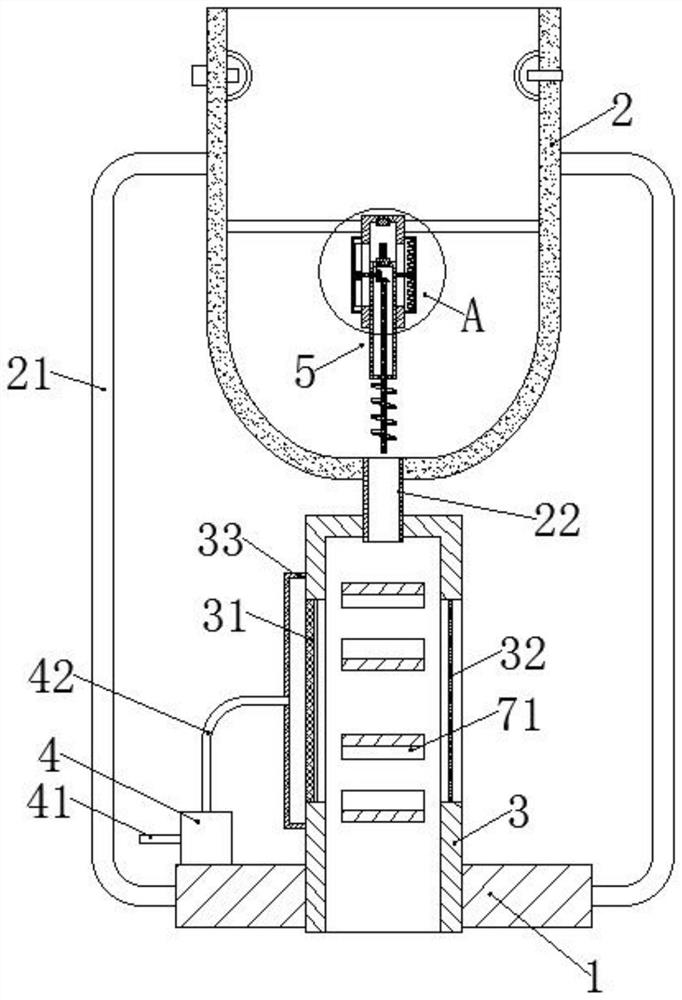

[0033] A feeding device for feed production with functions of removing impurities and preventing blocking, comprising a base 1, a hopper 2, a removing bin 3, a removing fan 4 and an anti-blocking device 5; the hopper 2 is located directly above the base 1, and the hopper 2 A support rod 21 is fixedly connected between the outer wall of the base and each side of the base 1, the lower part of the hopper 2 is arc-shaped, and the bottom of the hopper 2 is fixedly connected with a feeding pipe 22, and the impurity removal bin 3 is a cuboid cavity with an open bottom. structure, the bottom of the impurity removal bin 3 is fixed in the base 1, the center of the top plate of the impurity removal bin 3 is fixedly connected with the feeding pipe 22, and the left and right side plates of the impurity removal bin 3 are respectively fixed with the first filter screen 31 and the second Two filter screens 32, the outer wall of the left side plate of the miscellaneous bin 3 is fixedly connecte...

Embodiment 2

[0037] The difference from Example 1 is that it also includes the following:

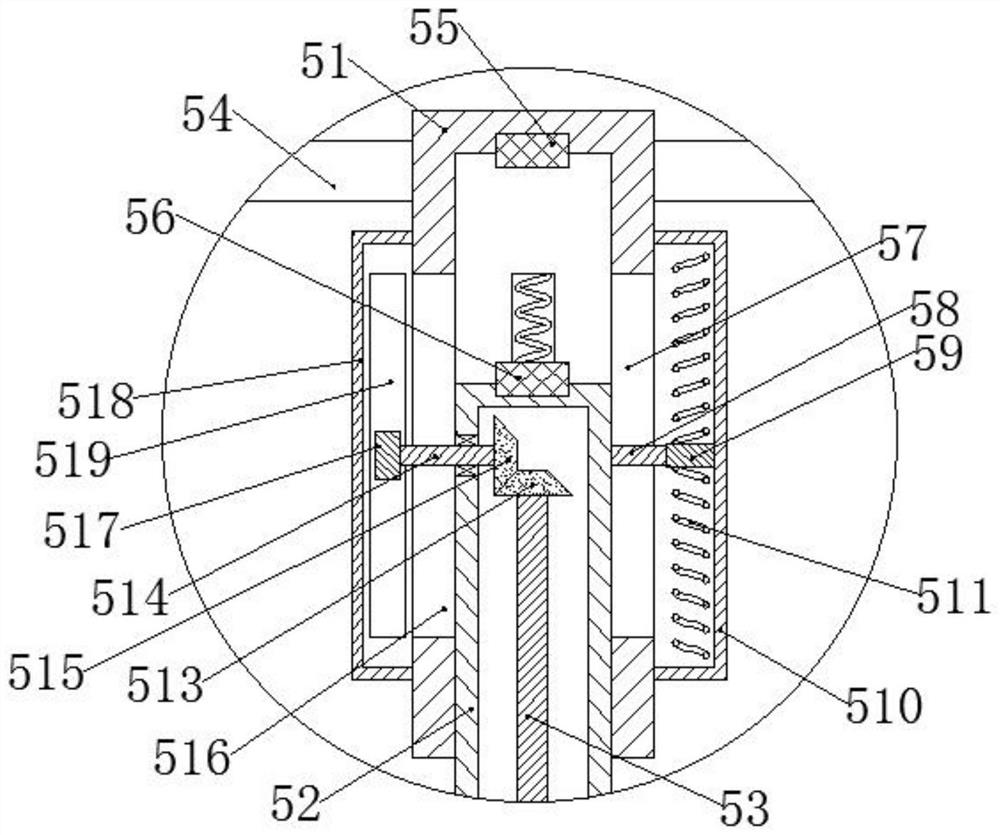

[0038] The anti-blocking device 5 includes a fixed cylinder 51, a lifting cylinder 52 and an anti-blocking rod 53; The inner wall of the fixed cylinder 51 is fixedly connected, the lower surface of the top plate of the fixed cylinder 51 is fixedly connected with an electromagnet 55, the electromagnet 55 is electrically connected with the external AC power supply, the lifting cylinder 52 is slidingly connected in the fixed cylinder 51, and the top surface of the lifting cylinder 52 is fixed Connected with the permanent magnet 56 corresponding to electromagnet 55, the front and rear side plates of fixed tube 51 and the right side plate are provided with the first chute 57, and the front and rear side plates of lifting tube 52 and the right side plate outer wall are fixedly connected with the first chute. The slide bar 58 corresponding to the chute 57 is slidably connected in the corresponding first ch...

Embodiment 3

[0042] The difference from Example 2 is that it also includes the following content:

[0043] The anti-blocking rod 53 is connected with the bottom plate of the lifting tube 52 in rotation, and the anti-blocking rod 53 below the lifting tube 52 is fixedly connected with a helical blade 512, and the top of the anti-blocking rod 53 is fixedly connected with a driven bevel gear 513, and the left side of the lifting tube 52 A shaft 514 is rotatably connected to the side plate, and the right end of the shaft 514 is fixedly connected with a driving bevel gear 515, the driving bevel gear 515 meshes with the driven bevel gear 513, and the left side plate of the fixed cylinder 51 is provided with a second chute 516 The shaft 514 is slidably connected in the second chute 516, the left end of the shaft 514 is fixedly connected with the driving gear 517, the outer wall of the left side plate of the fixed cylinder 51 is fixedly connected with the transmission box 518, and the inner wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com