Pre-condensation and impurity removal equipment for mixing natural gas synergistic additives

A synergistic additive, natural gas technology, used in lighting and heating equipment, steam/vapor condensers, machines using electrical/magnetic effects, etc. problems, to achieve the effect of improving the stability of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

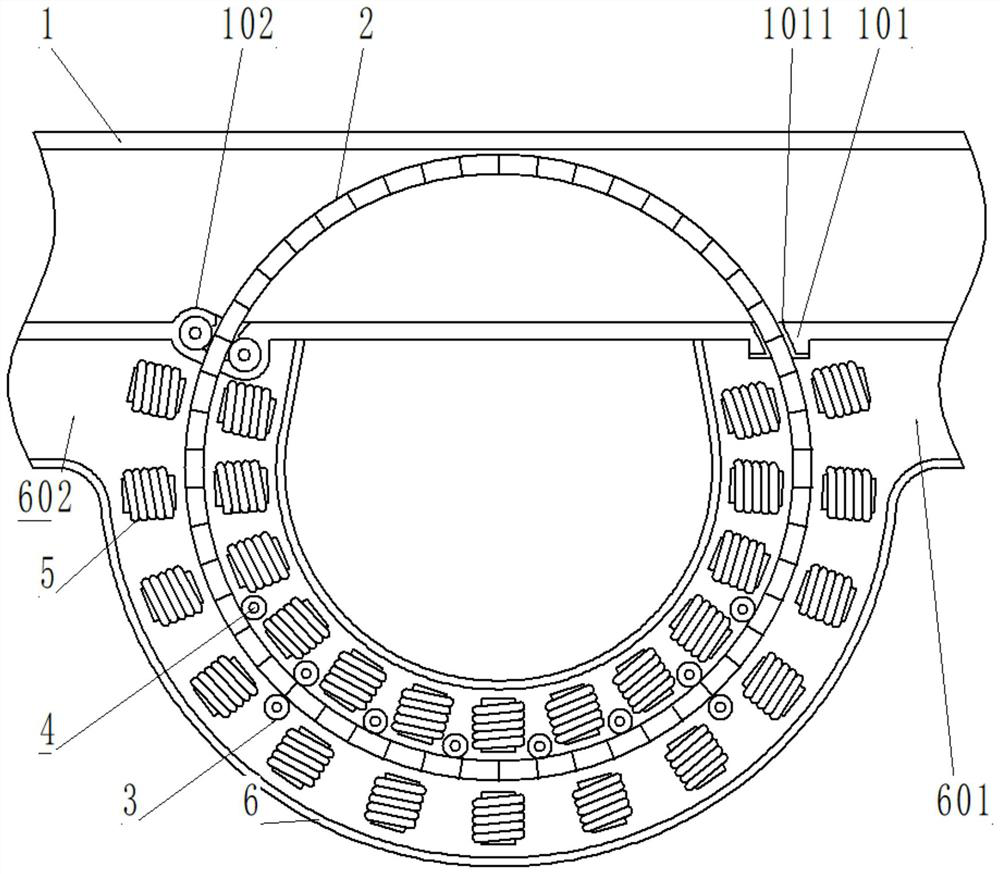

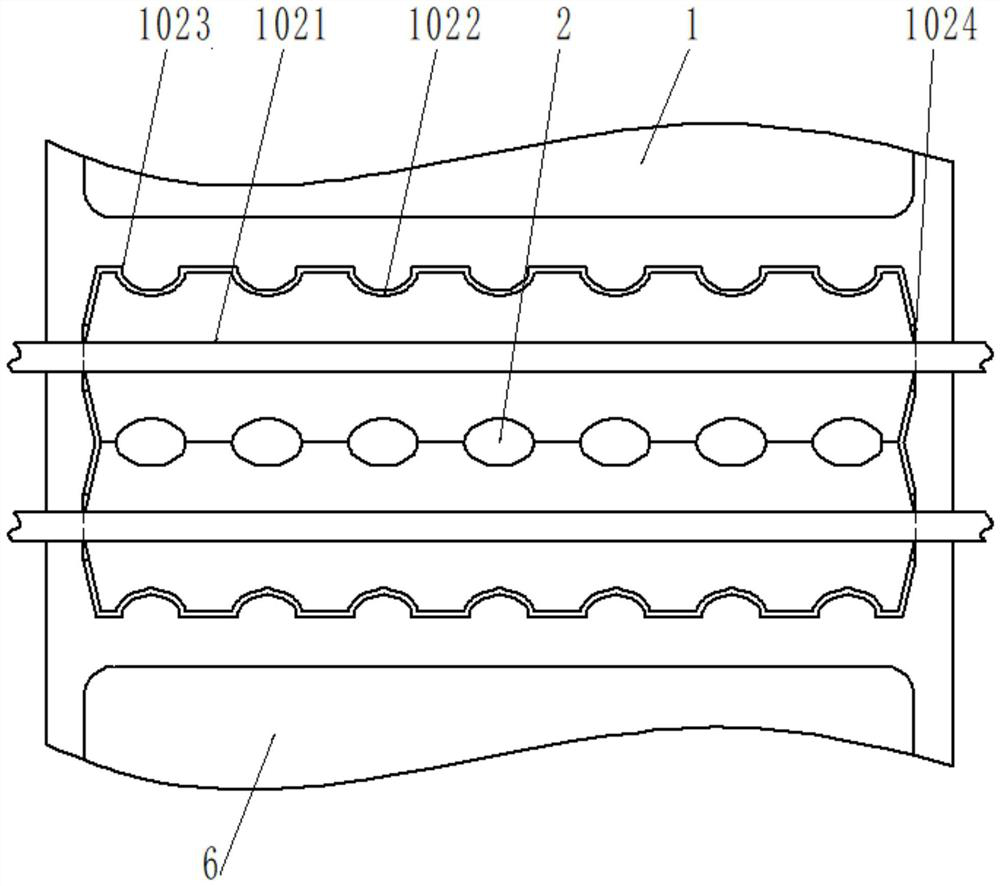

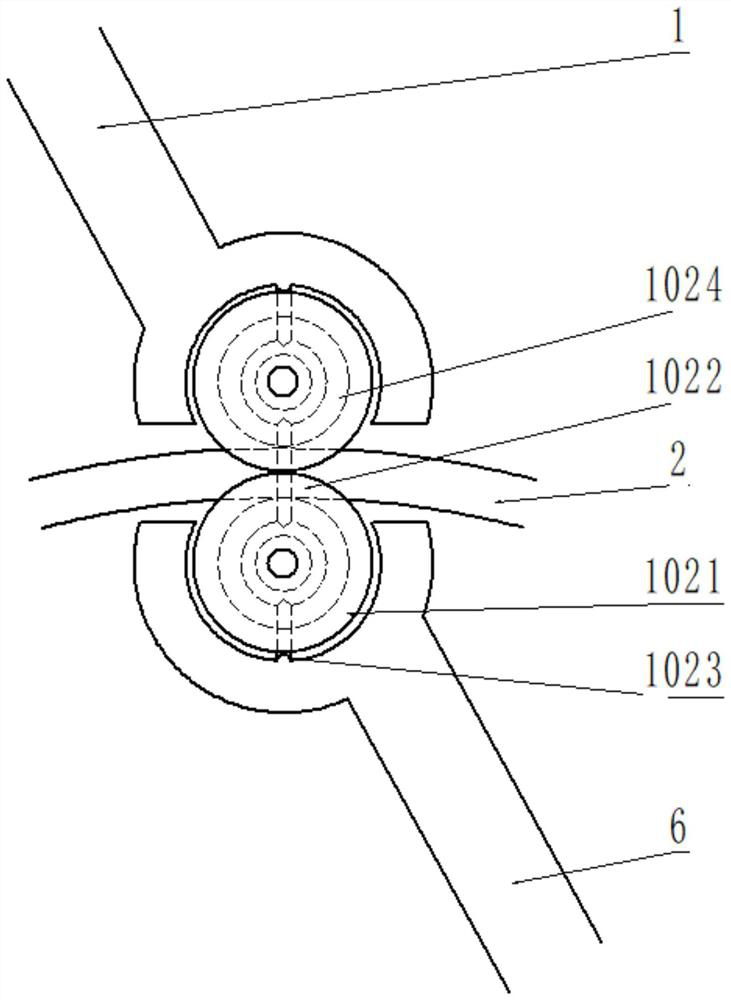

[0023] Pre-condensation and impurity removal equipment for natural gas synergistic additives, including: natural gas pipe 1, condensation ring 2, condensation ring support roller 3, condensation ring positioning roller 4, condensation ring excitation electromagnet 5 and external ventilation pipe 6.

[0024] Among them, the natural gas pipe 1 is a square pipe, and the lower pipe wall of the natural gas pipe 1 is provided with an inlet hole 101 and an outlet hole 102. The condensation rings 2 are circular rings, seven of which are arranged side by side. There is a gap between the condensation rings 2, and the upper area Extend into the natural gas pipe 1 through the inlet hole 101 and the outlet hole 102, the top of the condensation ring 2 is close to the top of the natural gas pipe 1, the condensation ring support roller 3 is set under the condensation ring 2, lifts the lower edge of the condensation ring 2, and the condensation ring positioning roller 4 It is arranged in the ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com