Method and device for recovering residual material and collecting dust at alumina unloading station

A technology of alumina and unloading station, which is applied in the direction of chemical instruments and methods, separation methods, combined devices, etc., can solve the problems of impurity removal and alumina flying repeatedly, so as to reduce operation time, reduce horizontal handling and upward The effect of moving and improving the working environment of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

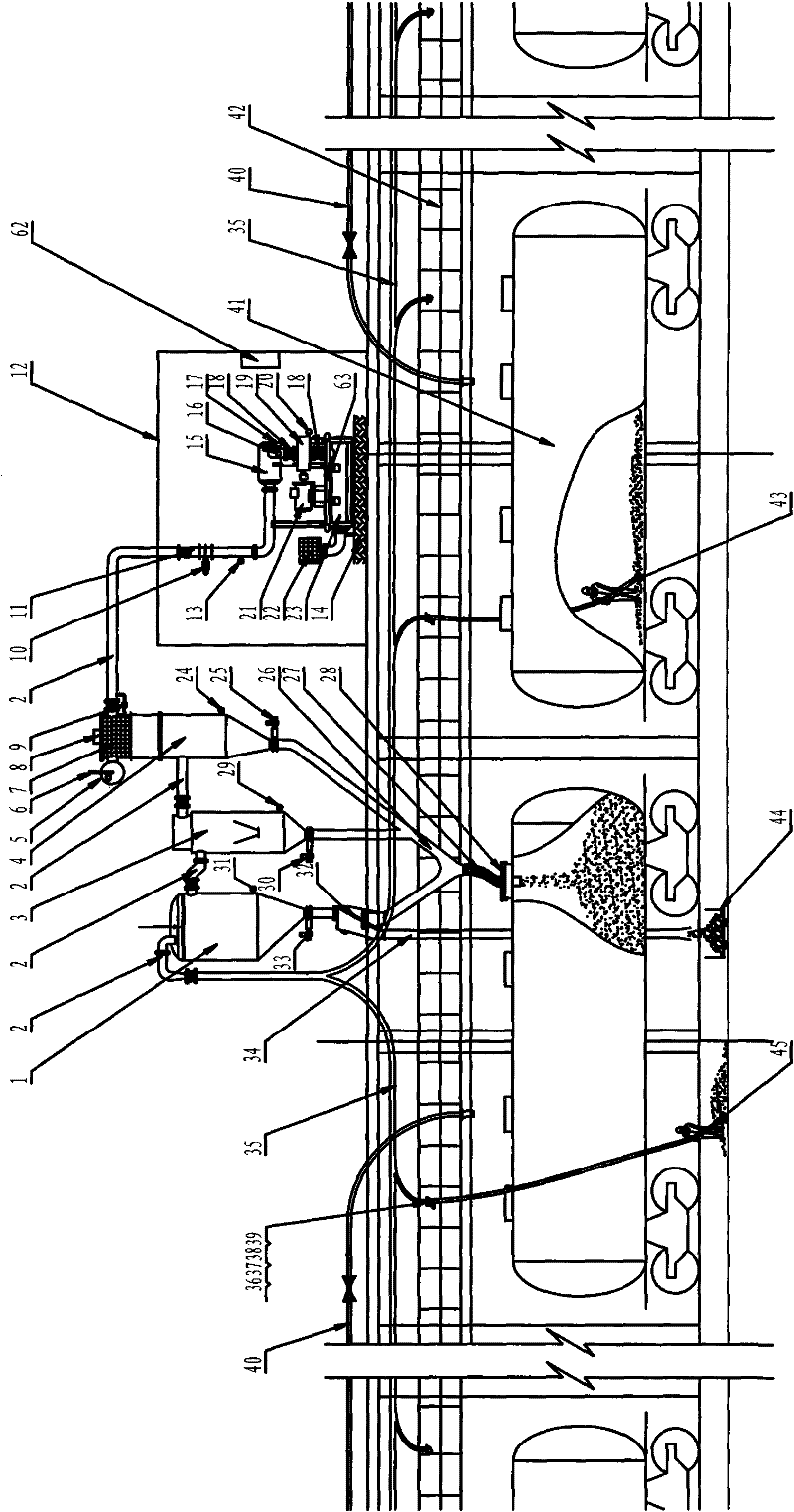

[0021] 1. General idea and structure layout

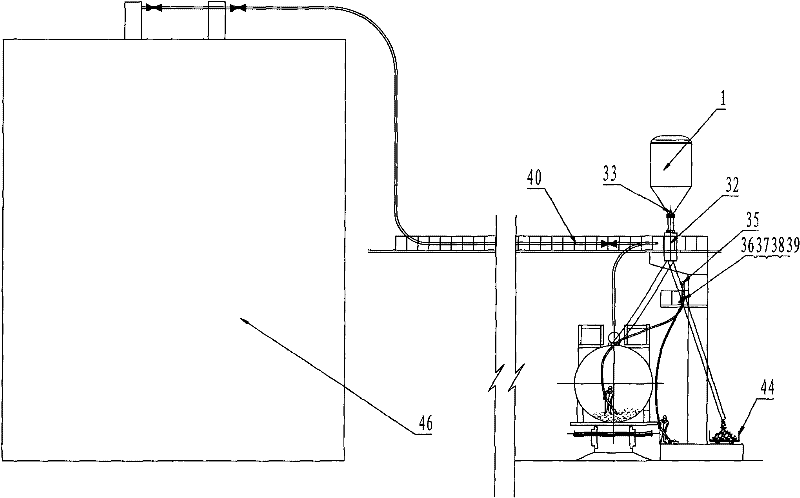

[0022] See attached figure 1 and figure 2 Summary of the invention: the present invention provides a method and device for alumina recovery and dust collection at the alumina unloading station of the aluminum industry, which adopts a negative pressure dust collection system;

[0023] The general idea is: to achieve on-site recycling and on-site charging;

[0024] ●Fixed design, the main equipment is installed on the central feeding platform of the unloading station;

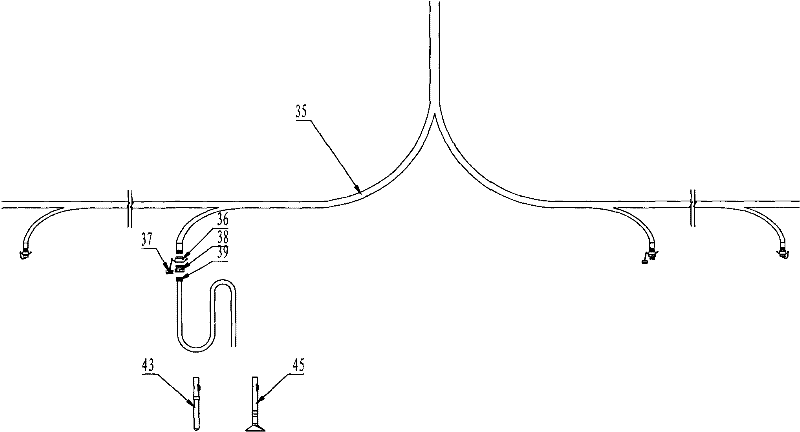

[0025] The negative pressure power is generated by the Roots vacuum pump, and the negative pressure dust collection pipe network is laid along the alumina unloading station. The negative pressure dust collection quick connector is designed corresponding to the tank parking space, and the connector is sealed with a cover when not in use;

[0026] ●Put the corresponding figure 1 The alumina tank car at the mouth of the middle and lower feeding nozzles should first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com