Longitudinal magazine

A vertical and magazine technology, applied in the direction of ammunition supply, weapon accessories, offensive equipment, etc., can solve the problems of large vertical height, limited magazine capacity, increase the height of the fire line of firearms, etc., to achieve convenient operation and portability, and reduce the height of the fire line , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

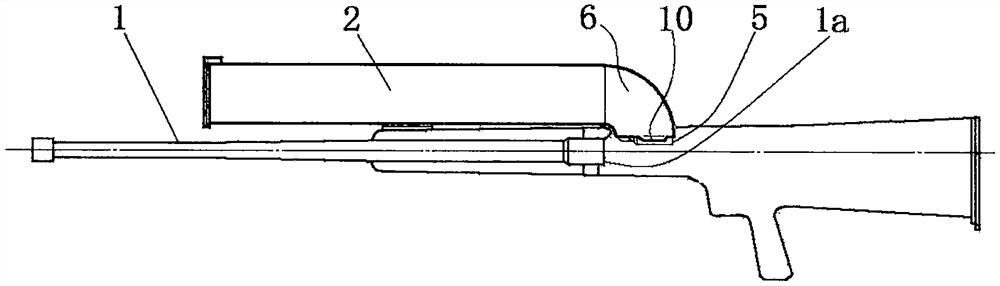

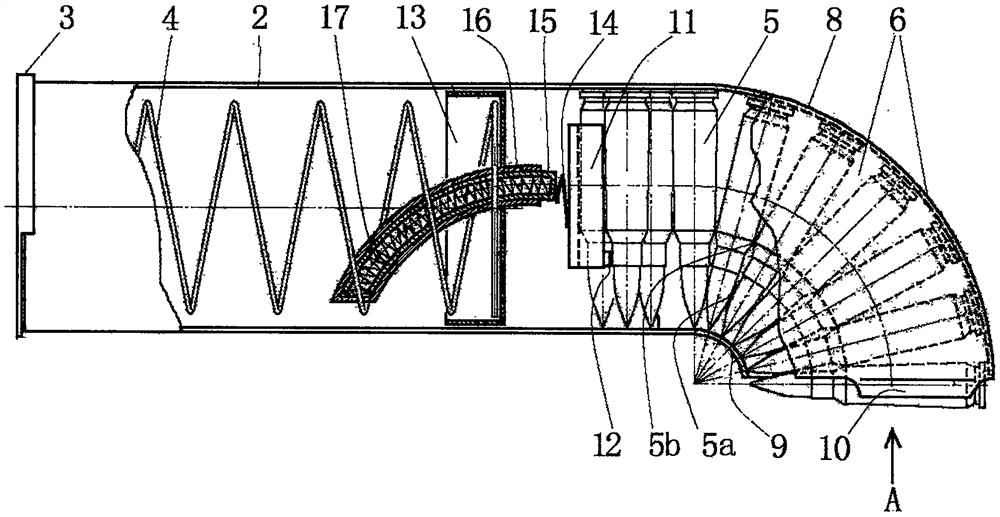

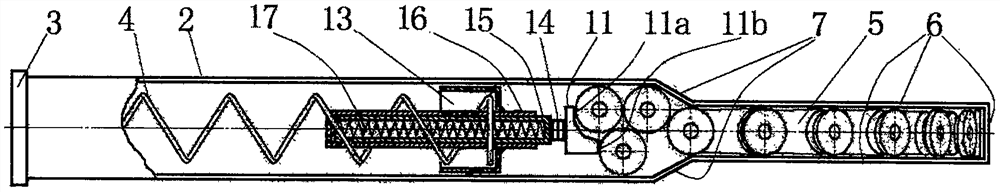

[0026] Embodiment 1: as figure 1 , 2 , shown in 3, a kind of longitudinal magazine, is arranged on the top of gun barrel 1 longitudinally, and the bottom of magazine is towards muzzle direction, and its main body double-row magazine body 2, is by four sides of upper, lower, left and right The straight cavity surrounded by the plate has a magazine cover 3 plugged in at its bottom, and the tail end of the push spring 4 is against the inboard of the magazine cover. The above-mentioned structures are all the same as the existing magazines. A group of bullets 5 housed in the double-row magazine body are arranged in double rows in a staggered manner, and the bullets are perpendicular to the gun barrel and the tip of the bullet is downward.

[0027] The key problem that this magazine needs to solve is how to guide and transfer the bullets perpendicular to the barrel in the double-row magazine to the ready position, that is, to be placed flat on the back and upper side of the tail en...

Embodiment 2

[0033] Embodiment 2: According to the longitudinal magazine described in embodiment 1, the longitudinal magazine is arranged longitudinally below the gun barrel 1 (as Figure 12 As shown), the bullet outlet is positioned at the back and below the rear end 1a of the barrel and is parallel to the barrel, and all the other structures are as described above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com