Ceramic Hot Gas Dust and Acid Removal Method

A hot gas, ceramic technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of high recycling cost, difficult to deal with secondary pollution, etc., to save energy, improve neutralization and High adsorption efficiency and high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

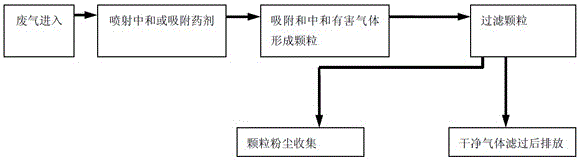

[0018] The filtration process of the ceramic hot gas dust removal and acid removal method provided by the present invention is as follows: figure 1 shown, including the following steps:

[0019] 1) Dissolve ceramic fiber in water, add positive and negative ion binder, the weight ratio of positive ion binder and negative ion binder is 3:5. The positive ion is silicon oxide, and the negative ion is starch, so that the negative charge on the fiber forms a repulsive force to stretch, and at the same time, the positive ion silicon oxide adsorbs the negative ion, and evenly distributes it to form the strength of the initial drying embryo. Suitable for use at high temperature, it can run at 450 degrees Celsius for a long time and 1000 degrees Celsius for a short time. Reduce high temperature waste gas for environmental protection treatment, the cost and equipment investment are generated. For example, biomass boiler emissions can achieve high-temperature gas directly filtered to me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com