Organic light-emitting panel and manufacturing method thereof

A technology of organic light-emitting panels and manufacturing methods, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., to achieve the effects of improving yield, ensuring continuity, and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

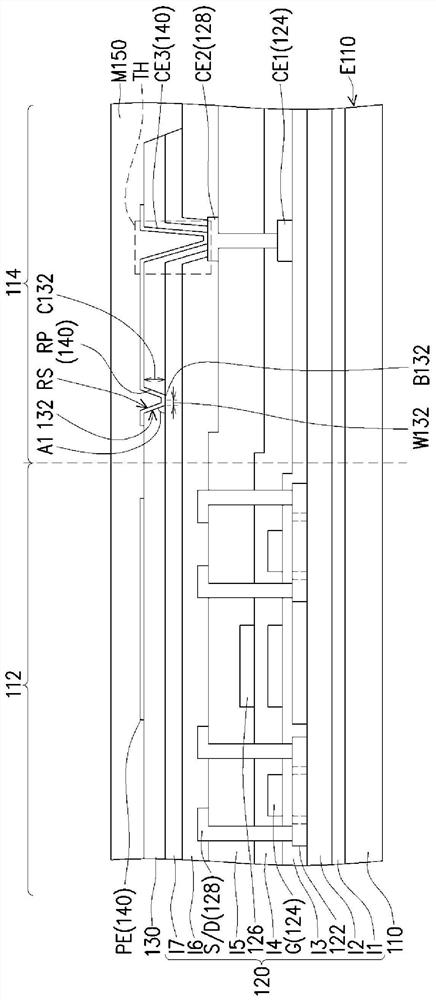

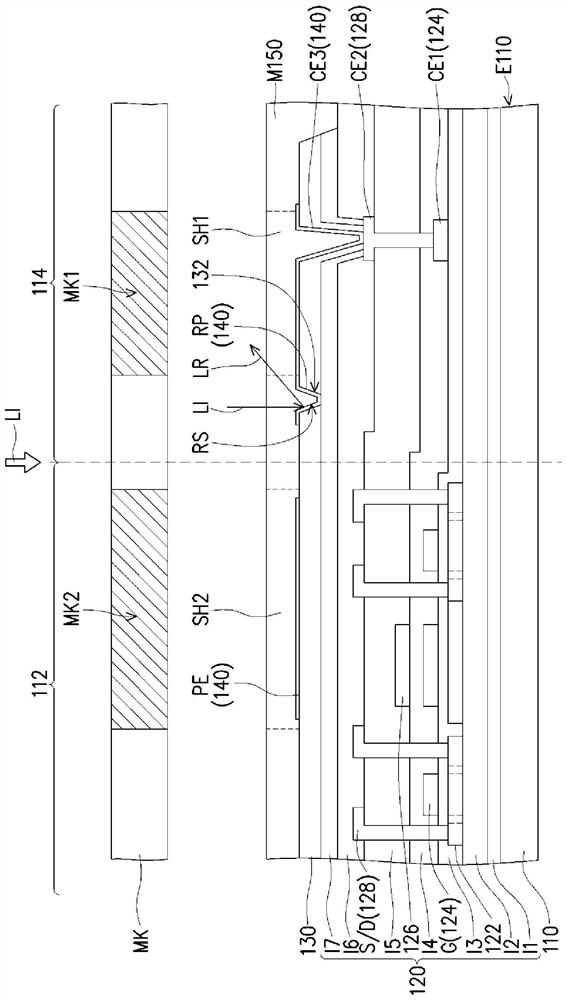

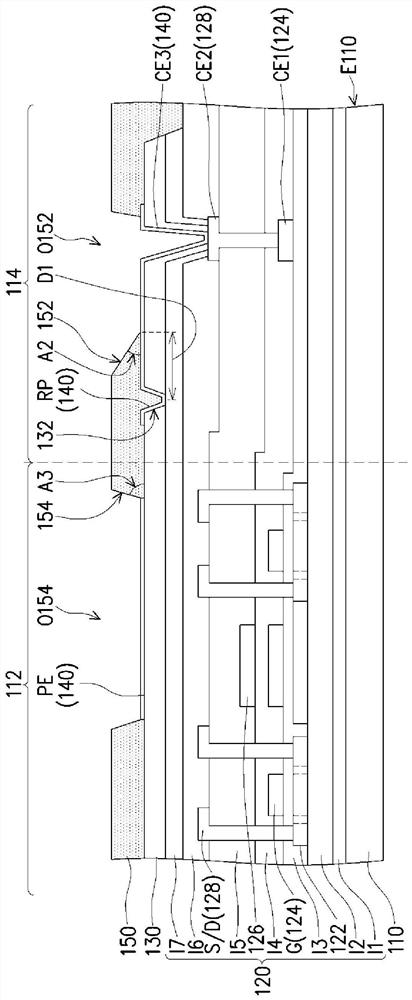

[0074] Figure 1 to Figure 4 A plurality of steps of the manufacturing method of the organic light emitting panel according to an embodiment of the present disclosure. exist figure 1 Among them, the substrate 110 and the active element array layer 120 , the planarization layer 130 , the reflective layer 140 and the photosensitive material layer M150 prefabricated on the substrate 110 are provided. The active device array layer 120 , the planarization layer 130 , the reflective layer 140 and the photosensitive material layer M150 are sequentially formed on the substrate 110 , for example. The substrate 110 can be a rigid substrate or a flexible substrate, and the material of the substrate 110 includes glass, polymer material, ceramics and the like. The substrate 110 has a display area 112 and a peripheral area 114 beside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com