Manufacture method of Artemisia argyi Levl. et Van leaf tea

A production method and controller technology, which can be applied in the direction of tea substitutes, etc., can solve the problems of labor-intensive, time-consuming, cumbersome processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

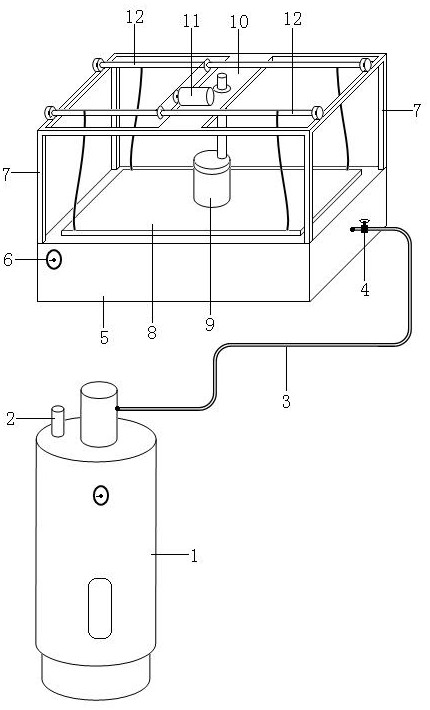

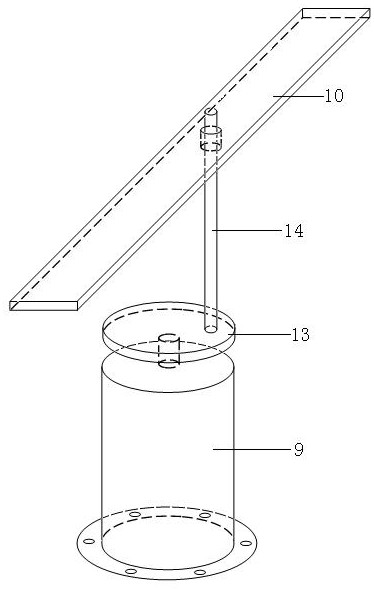

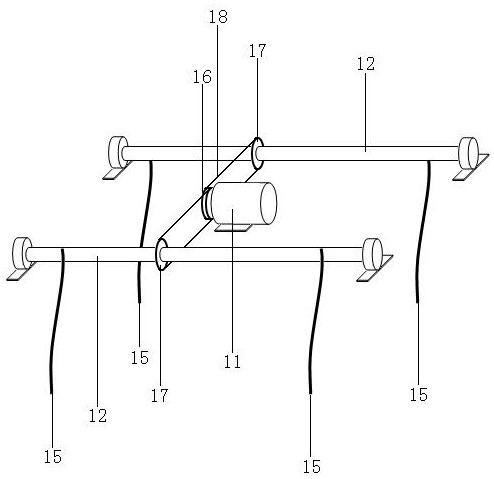

[0017] Now describe in detail the shape and structure of the present invention in conjunction with accompanying drawings and reference numerals:

[0018] Aicha tea making machine includes atmospheric pressure boiler 1, safety valve 2, steam pipe 3, valve 4, steam heating box 5, thermometer 6, frame 7, rubbing board 8, tea kneading reduction motor 9, supporting plate 10, lifting deceleration Motor 11, lifting shaft 12, eccentric disc 13, swinging shaft 14, lifting belt 15, lifting reduction motor sprocket 16, lifting shaft sprocket 17, chain 18, control box 19, power supply 20, display screen 21, multi-channel controller 22. Power cord 23;

[0019] The atmospheric pressure boiler is cylindrical and vertically installed on the ground, with a cylindrical safety valve on the top and a ring heater inside. The gas outlet of the valve is connected to the right side of the steam heating box;

[0020] The steam heating box is in the shape of a hollow cuboid made of metal, the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com