A rotary sugarcane ridge breaking machine

A rotary, sloughing technology, applied in agricultural machinery and implements, shovels, plows, etc., can solve the problems of lack of matching, time-consuming and laborious, low operation efficiency, etc., and achieve the effect of increasing the number of hair plants, good effect and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

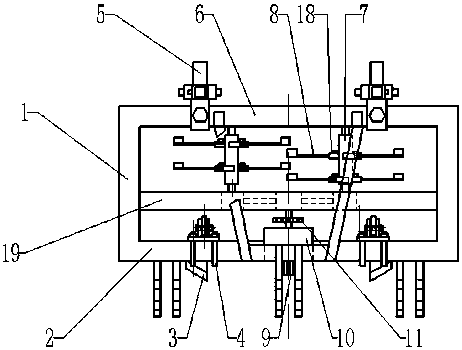

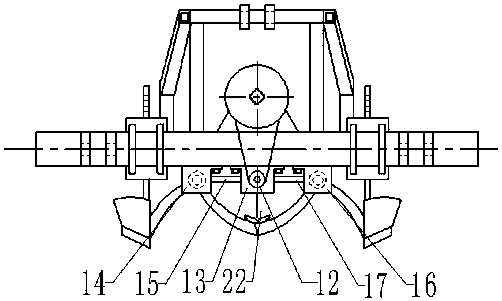

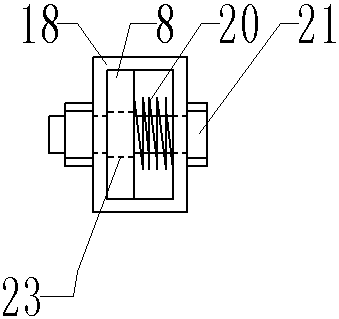

[0020] Such as figure 1 , figure 2 , Figure 4 As shown, a kind of rotary sugarcane breaking ridge loosening machine of the present embodiment comprises a suspension frame 1, a ridge breaking plow 3, a depth-limiting wheel 5, a loosening ridge mechanism, and a transmission mechanism; the number of the ridge breaking plows 3 is two One, installed on the front beam 2 of the suspension frame 1 through U-shaped bolts 4, the two are symmetrically arranged; the depth-gauge wheel 5 is fixed on the rear beam 6 of the suspension frame 1; The pine shaft 7 and the pine cutter 8 installed on the pine shaft 7; the pine shaft 7 is installed under the middle beam 19 and the rear beam 6 of the suspension frame 1, and is vertically arranged with the two; the transmission mechanism Installed on the suspension frame 1, the power is transmitted to the pine shaft 7, which drives the pine shaft 7 to rotate; the pine shaft 7 is two, arranged in parallel, and the direction of rotation is opposite,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com