A batch coloring equipment for cables

A batch and cable technology, which is applied in coatings, cleaning methods and tools, chemical instruments and methods, etc., can solve the problems of large manpower consumption, long coloring time, low coloring efficiency, etc., and achieve uniform and complete coloring , Improve coloring efficiency, save time for manual transportation and loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

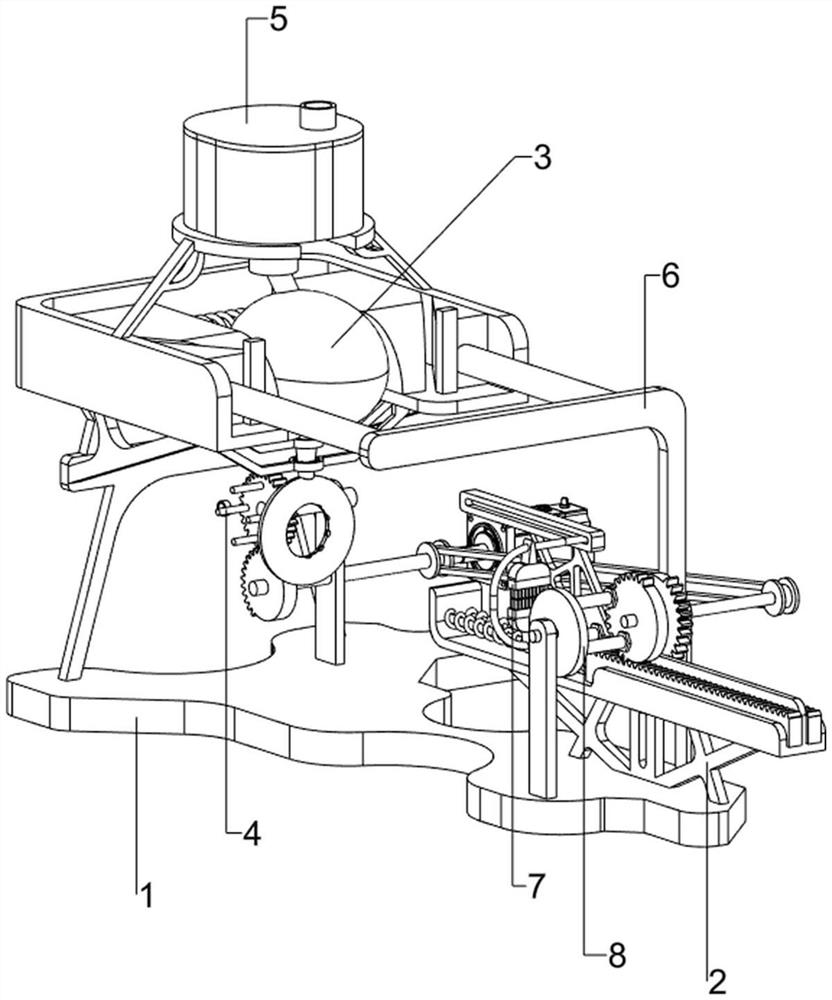

[0068] A cable batch coloring equipment, such as figure 1 As shown, it includes a base plate 1, a first bracket 2, a coloring mechanism 3 and a transport mechanism 4, the front and rear sides of the base plate 1 are provided with a first bracket 2, the rear first bracket 2 is provided with a coloring mechanism 3, and the base plate 1 is provided with transport mechanism 4.

[0069] When people need to color the material, first place the material on the transportation mechanism 4, start the transportation mechanism 4 to transport the material, then manually operate the coloring mechanism 3 to color the material, after the coloring is completed, close the transportation mechanism 4 , manually stop the operation of the coloring mechanism 3 and get final product.

Embodiment 2

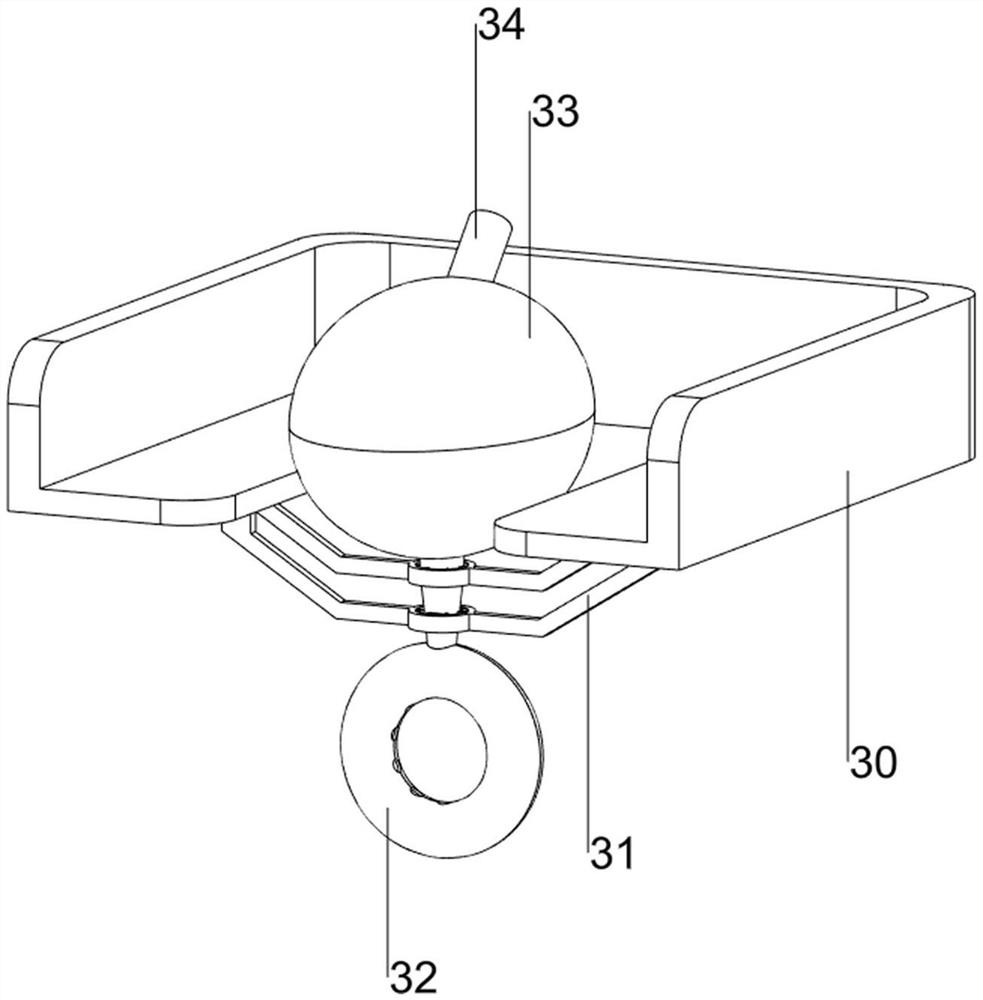

[0071] On the basis of Example 1, such as figure 2 As shown, the coloring mechanism 3 includes a first slide rail 30, a connecting bracket 31, a shader 32, an elastic hollow ball 33 and a water pipe 34, and the first support 2 at the rear is provided with a first slide rail 30, and the first slide rail The bottom of 30 is provided with a connecting bracket 31, the connecting bracket 31 is provided with a coloring device 32, the top of the coloring device 32 is provided with an elastic hollow ball 33, and the elastic hollow ball 33 is provided with a water pipe 34.

[0072] When people need to color the material, first the elastic hollow ball 33 is filled with paint through the water pipe 34, then the material is placed on the coloring device 32, and the elastic hollow ball 33 is extruded by manual operation, and the paint is released from the elastic hollow ball 33 The material can be evenly and completely colored by flowing out, and after the coloring is finished, the extrus...

Embodiment 3

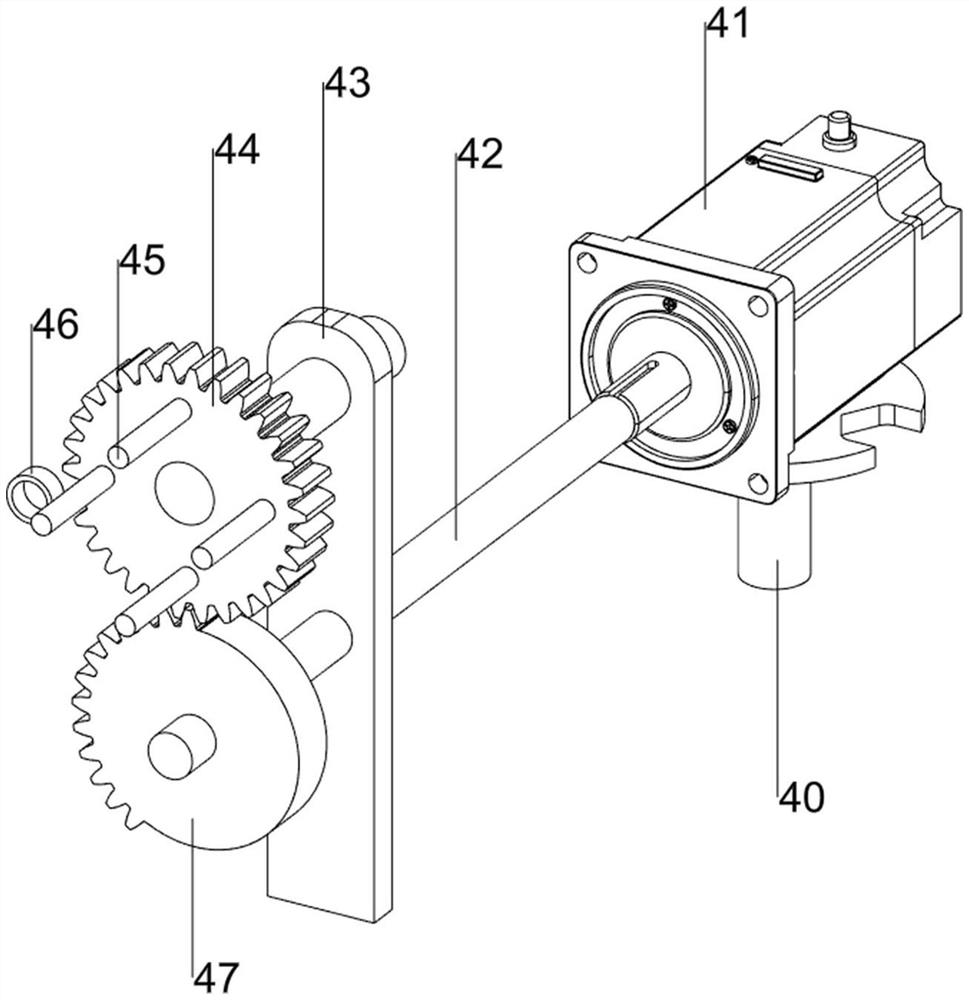

[0074] On the basis of Example 2, such as Figure 3 to Figure 7 As shown, the transportation mechanism 4 includes a support base 40, a servo motor 41, a first rotating shaft 42, a first bearing seat 43, a transmission gear 44, a first round rod 45, a clamping ring 46 and a first missing gear 47, and the bottom plate 1 The right part is provided with a supporting seat 40, and the supporting seat 40 is provided with a servo motor 41. The middle part of the rear side of the bottom plate 1 is provided with a first bearing seat 43, and the middle part of the first bearing seat 43 is rotatably connected with a first rotating shaft 42. The first rotating shaft 42 It is connected with the output shaft of the servo motor 41, the left part of the first rotating shaft 42 is provided with a first missing gear 47, and the upper part of the first bearing seat 43 is rotatably connected with a transmission gear 44, and the transmission gear 44 is meshed with the first missing gear 47, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com