A kind of manufacturing equipment for the bottom support seat of small plastic Christmas tree

A technology for manufacturing equipment and Christmas trees. It is applied in the direction of pretreatment surface, device for coating liquid on the surface, coating, etc. It can solve the problems of difficult batch processing, short time, and long time, so as to speed up the air-drying speed , saving air-drying time, saving time for manual cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

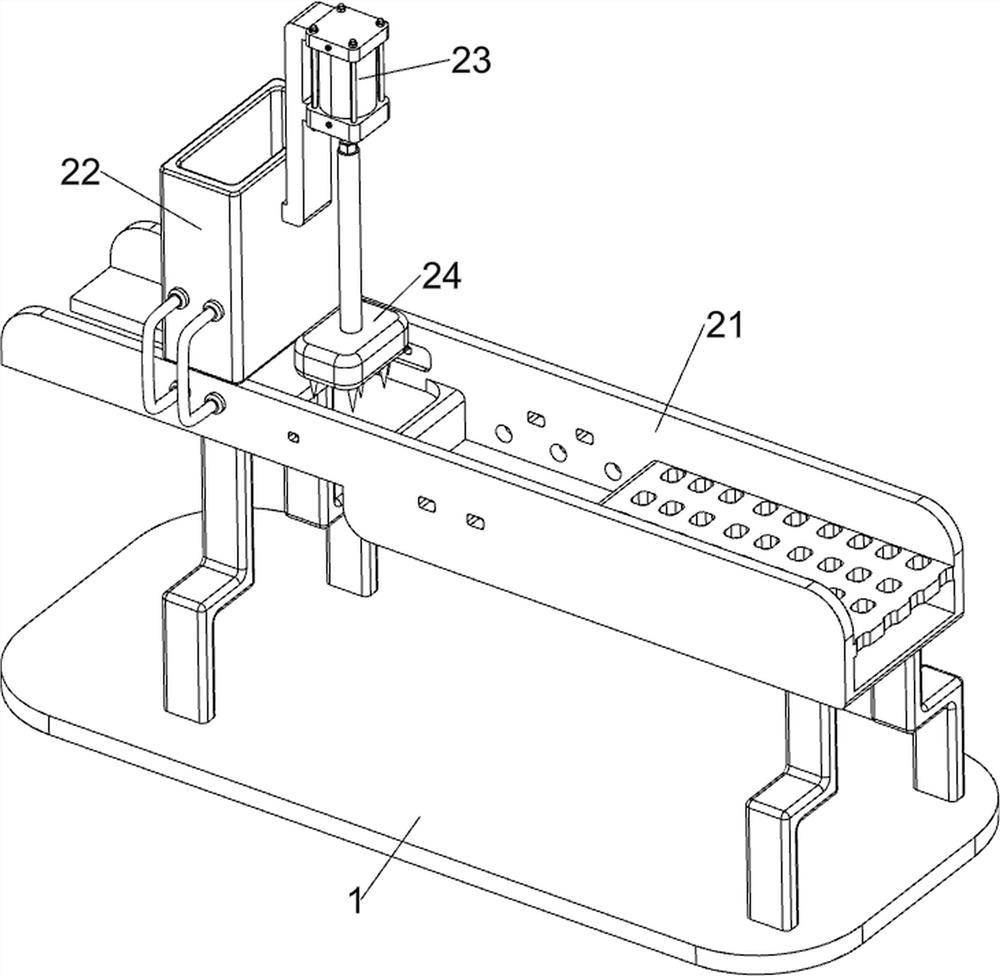

[0062] An equipment for the manufacture of small plastic Christmas tree base supports such as figure 1 As shown, it includes a base 1 , a pressing mechanism 2 and a clamping mechanism 3 , the pressing mechanism 2 is provided on the base 1 , and the clamping mechanism 3 is provided between the base 1 and the pressing mechanism 2 .

[0063] When people need to process the material, the material is placed on the clamping mechanism 3, and then the pressing mechanism 2 is started, and the pressing mechanism 2 drives the clamping mechanism 3 to clamp the material, and the pressing mechanism 2 presses and processes the material, and the processing is completed Finally, people close the pressing mechanism 2, and the clamping mechanism 3 releases the material, and people can take out the material.

Embodiment 2

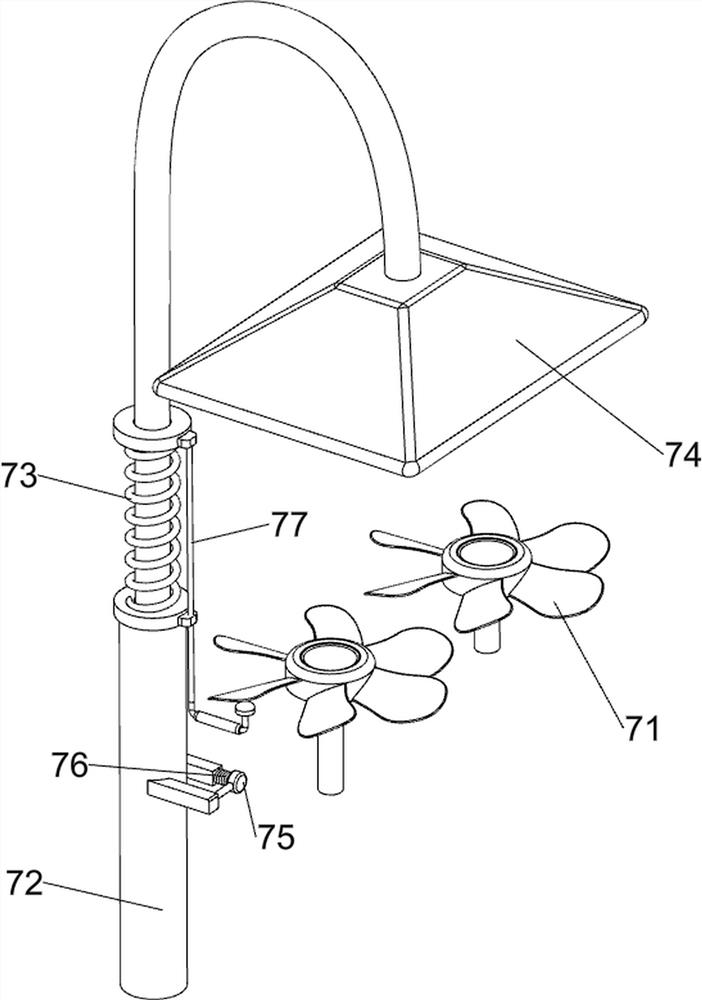

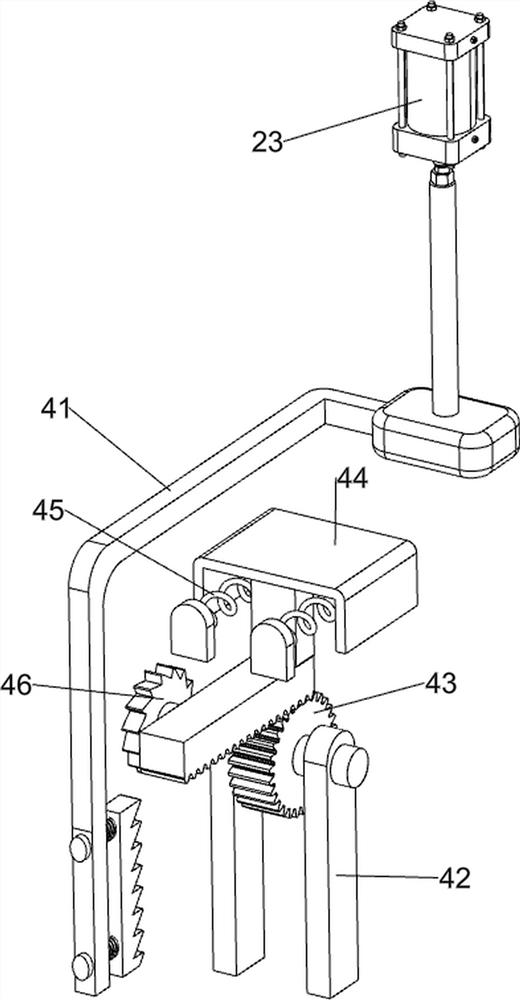

[0065] On the basis of Example 1, such as Figure 2 to Figure 7 As shown, the pressing mechanism 2 includes a support frame 21, a fixed frame 22, a cylinder 23 and a pressing block 24, the base 1 is provided with a support frame 21, the left part of the support frame 21 is provided with a fixed frame 22, and the right part of the fixed frame 22 is provided with a Cylinder 23, the bottom of cylinder 23 is provided with briquetting block 24.

[0066] When people need to process the material, they put the material on the support frame 21, then people start the cylinder 23, the cylinder 23 stretches, drives the pressing block 24 to move down, and the material can be processed, and the cylinder 23 shrinks and resets , Drive the briquetting block 24 to move upwards and reset, and people can take out the material from the support frame 21. After the material processing is completed, people close the cylinder 23, and the briquetting block 24 stops moving.

[0067] The clamping mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com