Piston rod cutting equipment for hydraulic oil cylinder production

A technology of cutting equipment and hydraulic cylinders, applied in metal processing equipment, large fixed members, maintenance and safety accessories, etc., can solve the problems of inconvenient operation, unreliable safety, single function, etc., and achieve the effect of easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

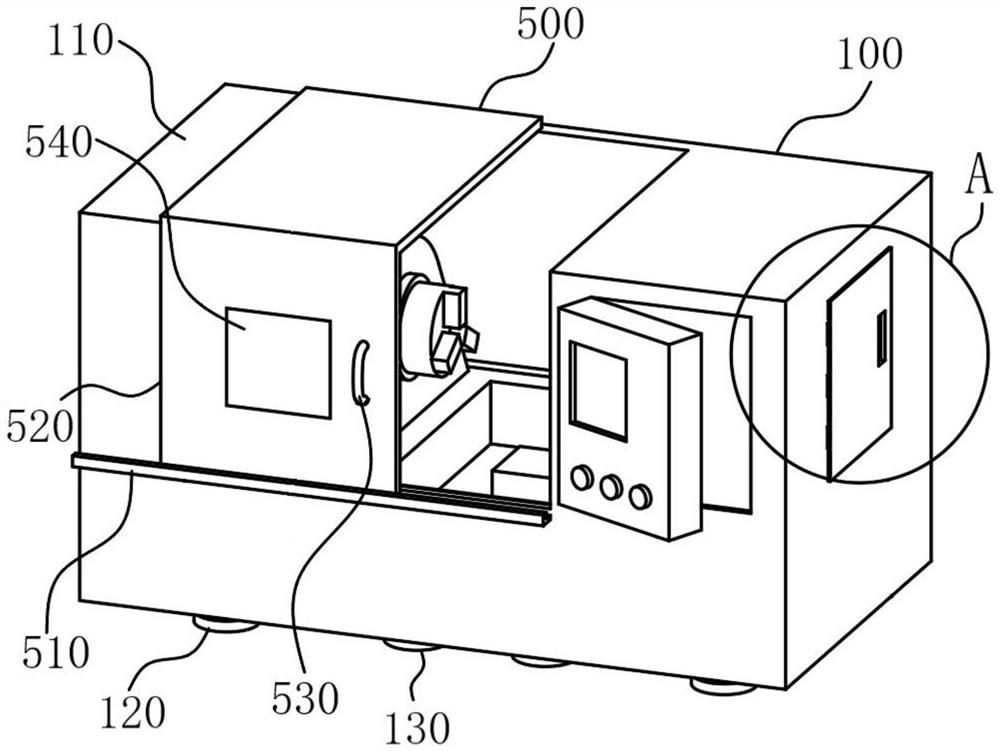

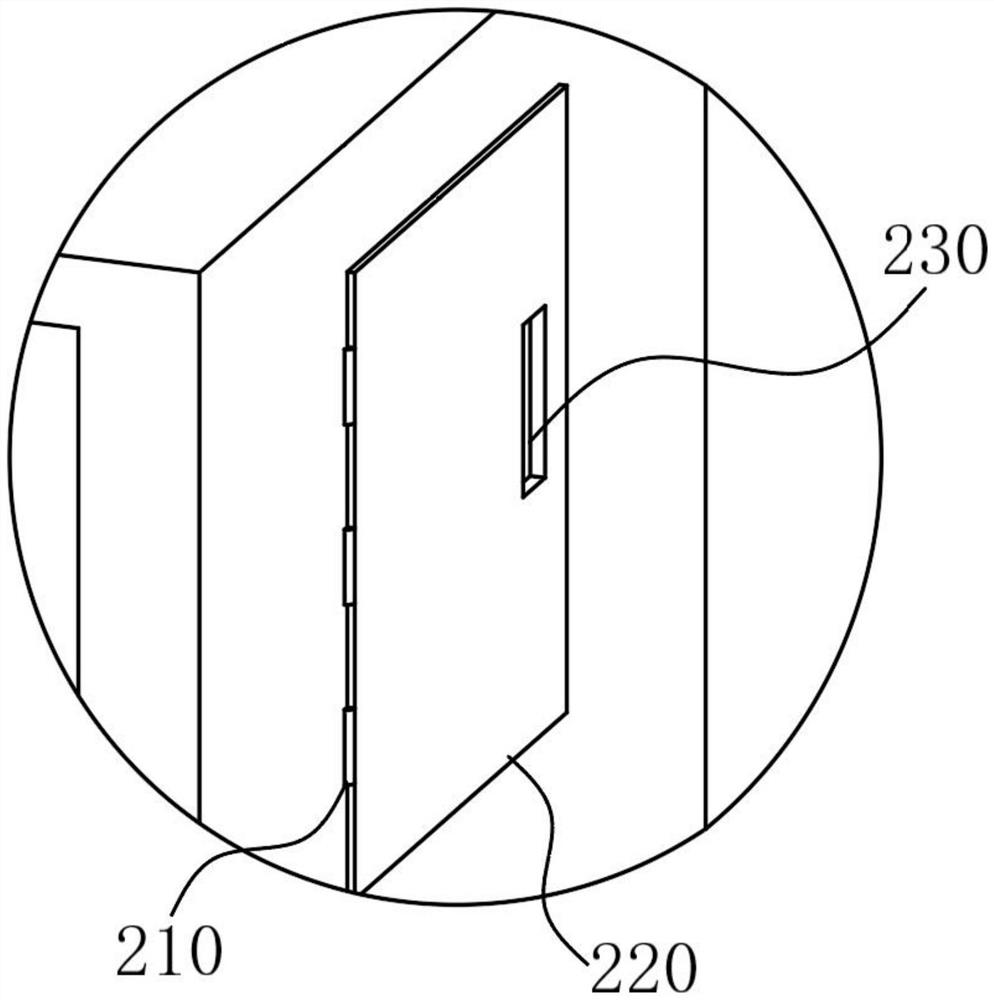

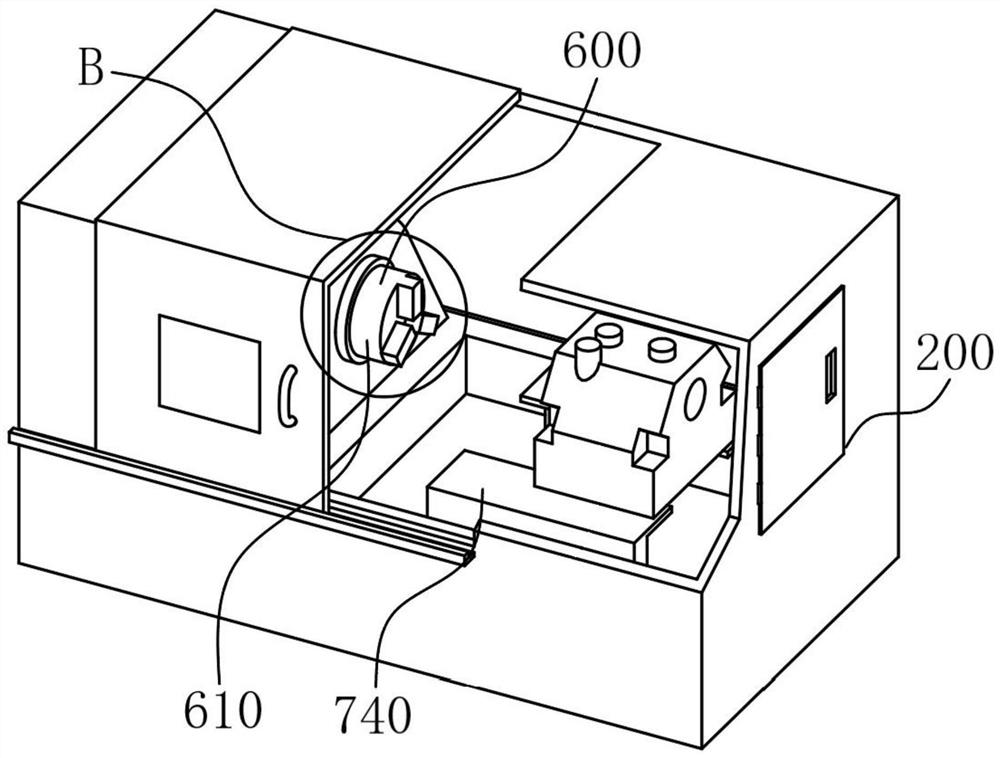

[0034] refer to figure 1—7. The present invention is a piston rod cutting equipment for hydraulic cylinder production, including a casing structure 100, a repair device 200, a control device 300, a power device 400, a sliding door mechanism 500, a cutting device 600, and a feeding device 700. The casing structure 100 includes a shell 110 and foot pads 120. The shell 110 is an internal hollow structure. One end of several foot pads 120 is welded to the outer lower surface of the shell 110. Among them, there are eight foot pads 120, and the foot pads 120 are mainly connected to the shell 110. connection, which plays the role of support. The repair device 200 includes a first hinge 210 and an alloy plate 220. One end of several first hinges 210 is connected to the outer surface of the shell 110, and several first hinges 210 are rotatably matched with the alloy plate 220. , wherein, there are three first hinges 210, the first hinge 210 is mainly connected with the alloy plate 220,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com