A method for preparing antibacterial particles containing ag on the surface of pure titanium or titanium alloy

An antibacterial particle, titanium alloy technology, applied in metal material coating process, coating and other directions, can solve the problems of complex process, high cost, low processing efficiency, etc., to achieve simple and fast operation, short preparation time, and wide application range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

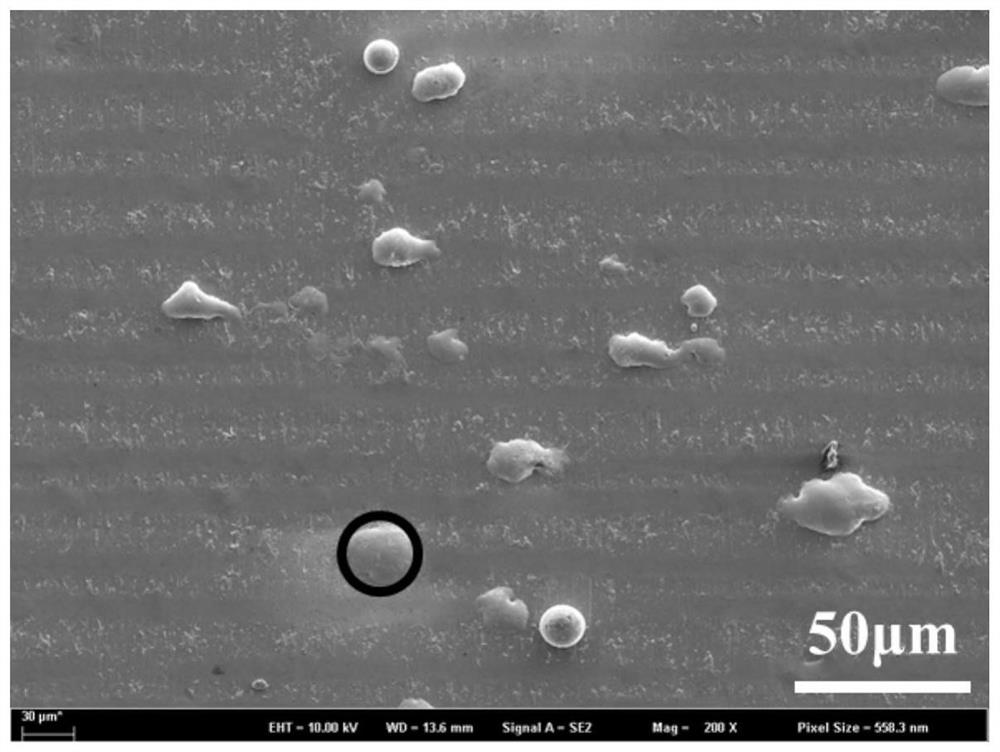

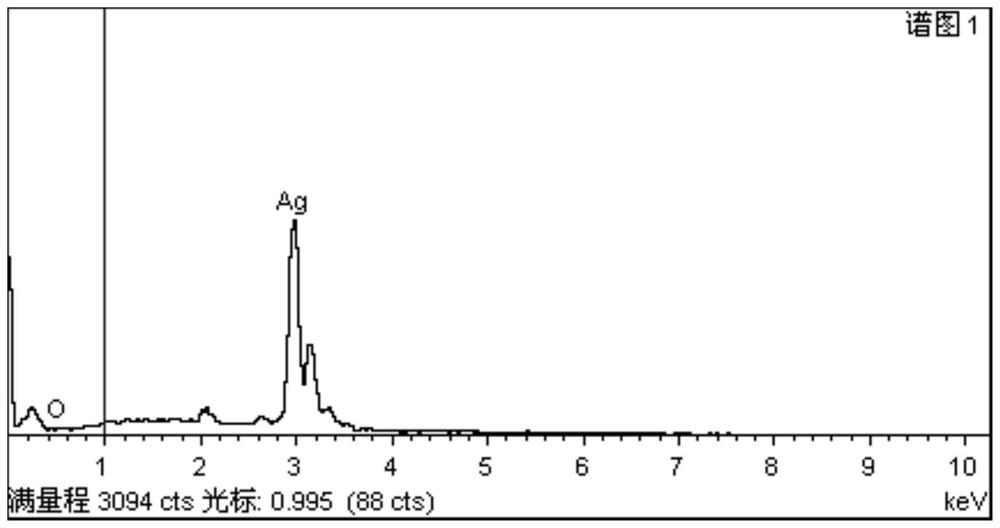

[0036] Embodiment 1: Preparation of Ag particles on the surface of Ti-6Al-4V alloy

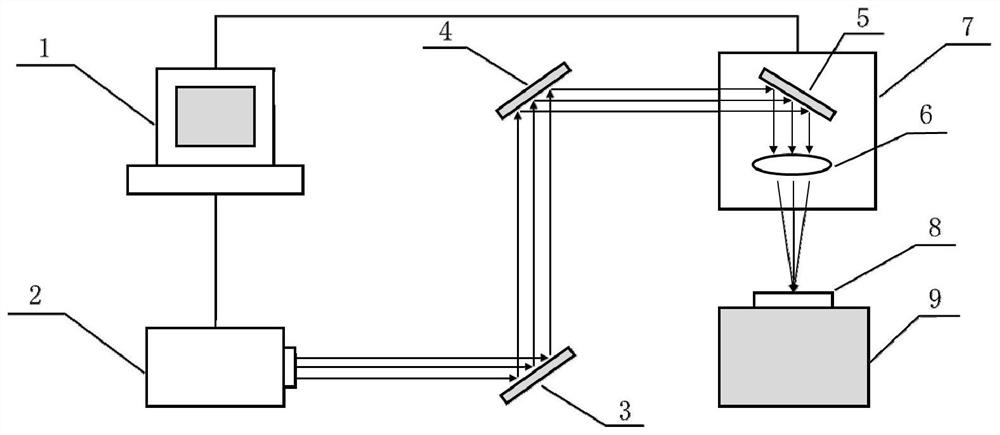

[0037] Such as figure 1 As shown, the structure of the fiber laser device used in the present invention includes a control computer 1, the control computer 1 is connected with the laser 2 and the vibrating mirror system 7, and the laser light emitted by the laser 2 is reflected to the vibrating mirror through the reflector 3, the reflector 4 and the reflector 5 The system 7 focuses on the titanium alloy sample 8 after passing through the focusing lens 6 , and the sample 8 is placed on the sample stage 9 .

[0038] The above-mentioned device is now used to test the Ti-6Al-4V alloy sample with a length × width × thickness of 10 × 10 × 1mm. The operation steps are as follows:

[0039] (1) Pretreatment of Ti-6Al-4V alloy samples: mechanically grind and polish the Ti-6Al-4V alloy samples, and then immerse them in acetone, alcohol and deionized water for 5 min, respectively, for ultrasonic cleaning...

Embodiment 2

[0043] Example 2: Ti-6Al-4V Alloy Selective Design Region Modification

[0044] The above-mentioned device is now used to test the Ti-6Al-4V alloy sample with a length × width × thickness of 10 × 10 × 1mm. The operation steps are as follows:

[0045] (1) Pretreatment of Ti-6Al-4V alloy samples: mechanically grind and polish the Ti-6Al-4V alloy samples, and then immerse them in acetone, alcohol and deionized water for 5 min, respectively, for ultrasonic cleaning, and then dry them for use;

[0046] (2) Silver foil attachment: Place the pretreated Ti-6Al-4V alloy sample on a clean plane with the polished side facing up, and then place the prepared silver foil on the Ti-6Al-4V alloy On the surface, place a layer of smooth paper on top of the silver foil, attach the silver foil to the surface of the Ti-6Al-4V alloy by pressing, remove the surface paper, and leave the silver foil attached sample for later use;

[0047] (3) Place Ag-attached Ti-6Al-4V alloy sample 8 in such as fi...

Embodiment 3

[0049] Embodiment 3: Preparation of Ag particles on the surface of pure titanium

[0050] The above-mentioned device is now used to test a pure titanium sample with a length × width × thickness of 10 × 10 × 1mm, and the operation steps are as follows:

[0051] (1) Pretreatment of pure titanium samples: mechanically grind and polish the pure titanium samples, then immerse them in acetone, alcohol and deionized water in order to perform ultrasonic cleaning for 5 minutes respectively, and then dry them for use;

[0052] (2) Silver foil attachment: Place the pretreated pure titanium sample on a clean plane with the polished side facing up, then place the prepared silver foil on the pure titanium surface, and place a pad on top of the silver foil. A smooth paper surface, attach the silver foil to the pure titanium surface by pressing, remove the surface paper surface, and leave the silver foil attached sample for later use;

[0053] (3) Place the pure titanium sample 8 attached wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com