Marine thermal expansion pipe compensation device

A compensation device and thermal expansion technology, which is applied in expansion compensation devices for pipelines, pipe components, pipes/pipe joints/fittings, etc., can solve the problems of bellows compensators that are easy to break, low safety performance, and high construction costs. Achieve the effect of reducing the difficulty of laying and installation, low cost and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

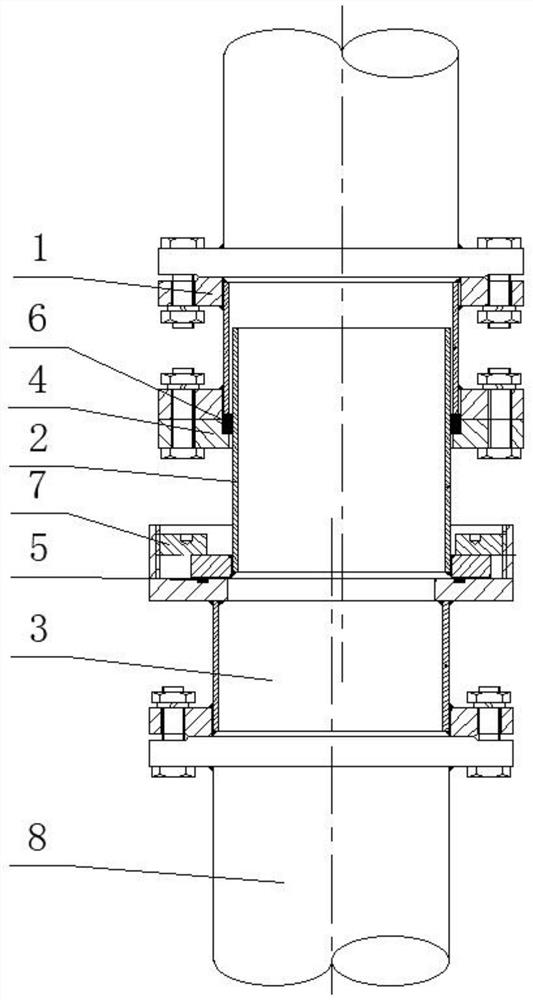

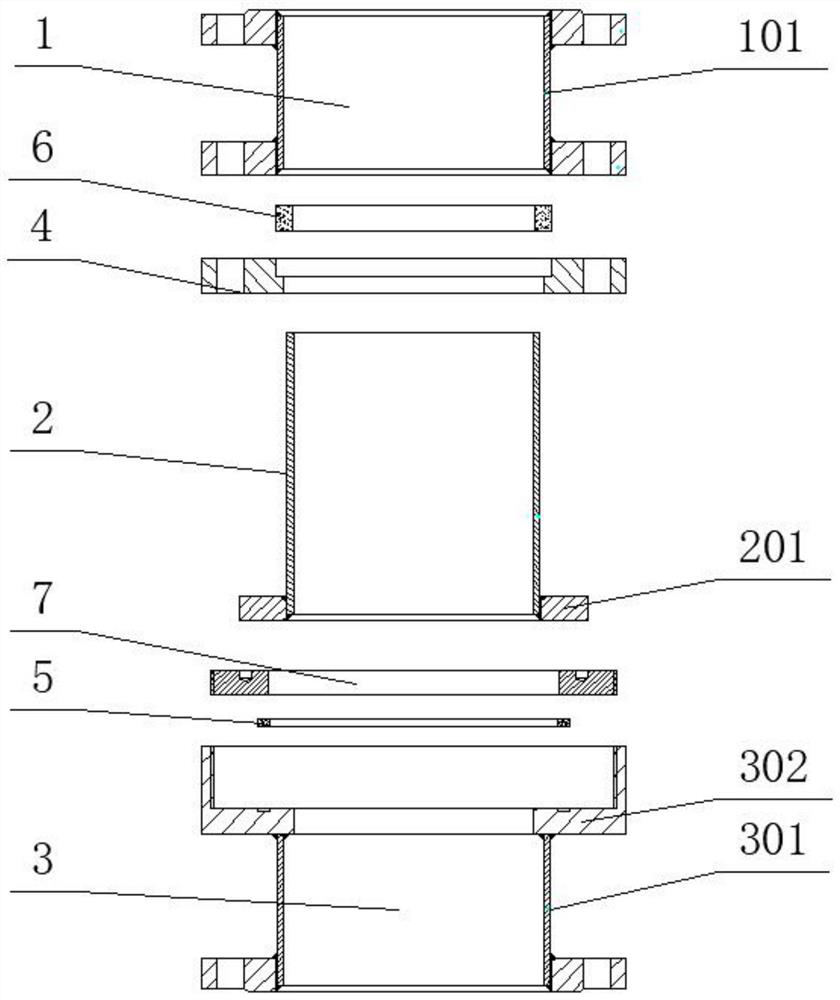

[0032] The technical solutions in this embodiment will be clearly and completely described below in conjunction with the accompanying drawings in this embodiment. However, this should not be construed as limiting the present invention to specific embodiments, but only for explanation and understanding:

[0033] Such as figure 1 and figure 2 As shown, this embodiment provides a marine thermal expansion tube compensation device, including a first base body 1, a sliding tube 2, a second base body 3, a gland 7, a loose flange 4, a flat sealing ring 5 and a radial Sealing ring 6.

[0034] The first seat body 1 includes a first pipe body 101 and two flanges. The first pipe body 101 is in the shape of a round pipe and is made of stainless steel. The two flanges can be made of 20# steel or stainless steel. The flanges are respectively welded to both ends of the first pipe body 101 .

[0035] The sliding tube 2 is in the shape of a circular tube, and the outer diameter of the slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com